Novel flue gas desulfurization method

A flue gas, a new type of technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of no obvious cooling, low desulfurization efficiency, huge equipment, etc., to extend the flue gas flow path and improve the desulfurization effect , Improve the effect of processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

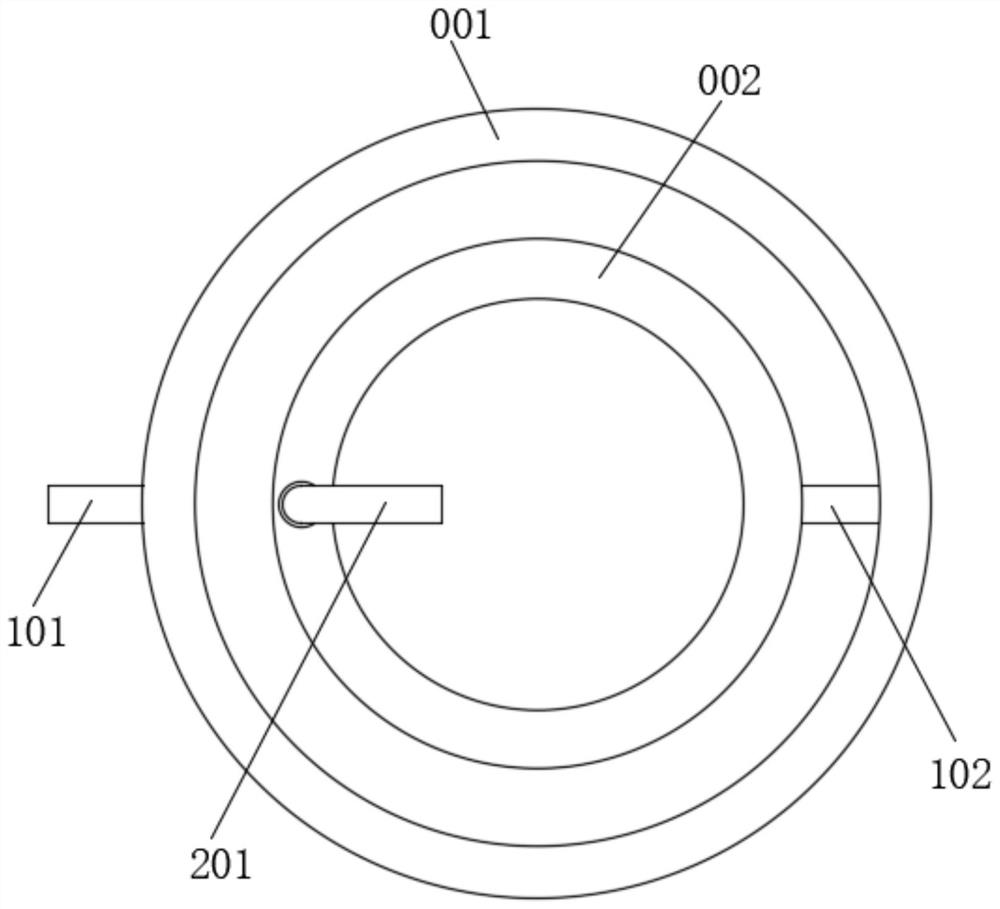

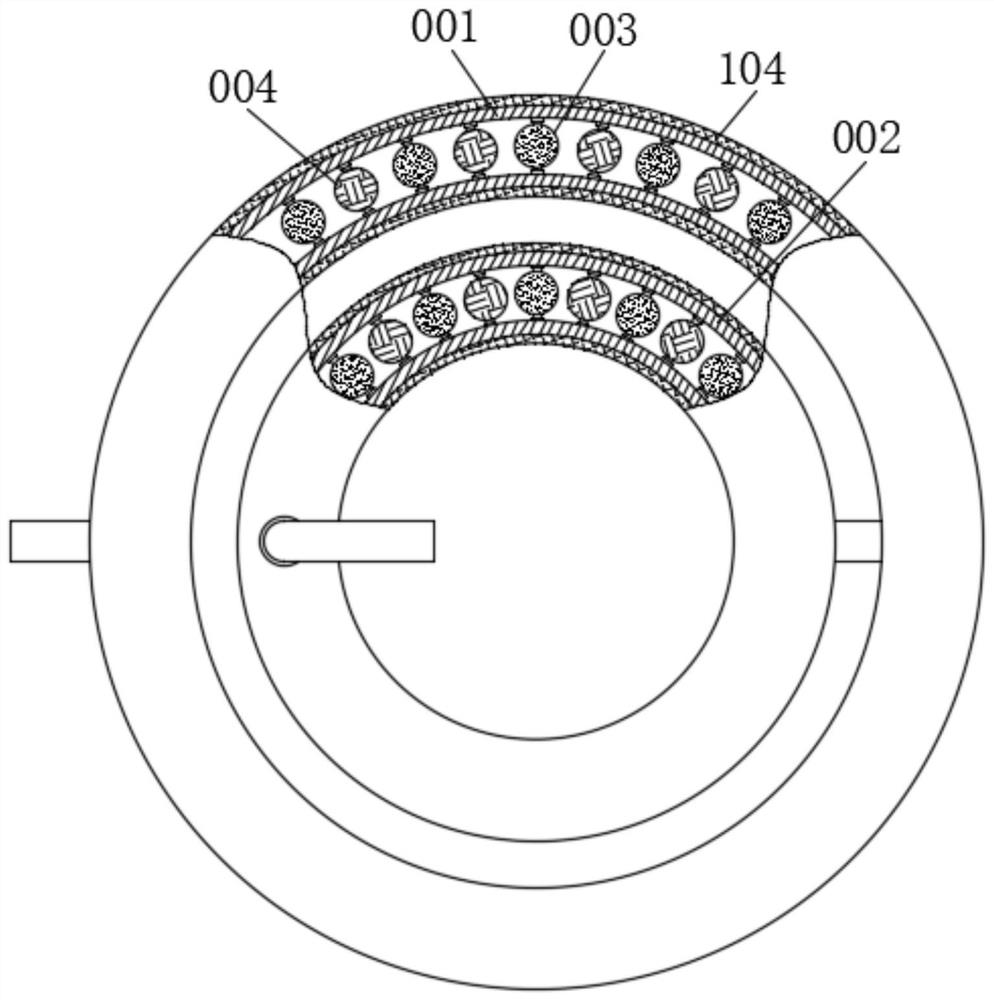

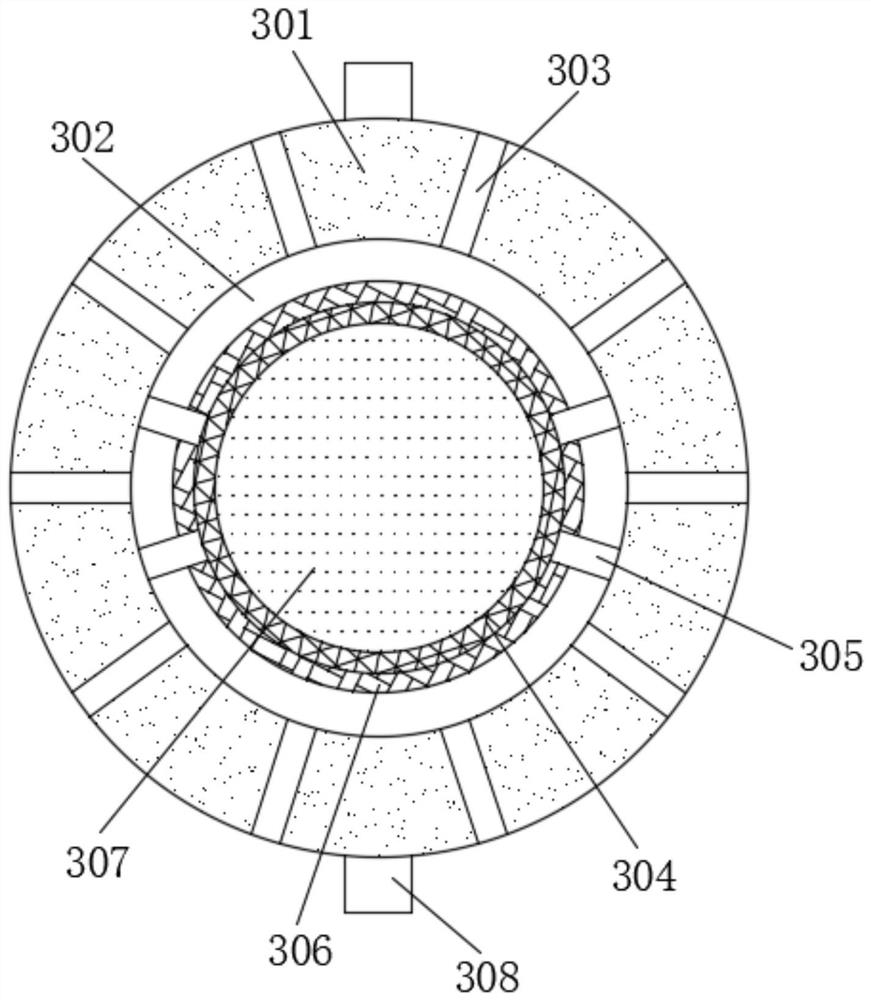

[0044] see Figure 1-5 , a new flue gas desulfurization method, comprising a desulfurization device, the desulfurization device includes a large annular pipe 001, a small annular pipe 002, the small annular pipe 002 is arranged inside the large annular pipe 001, through the large annular pipe 001, the intake pipe 101, the guide The arrangement of air pipe 102, small annular pipe 002 and air outlet pipe 201 can extend the flue gas flow path and improve the desulfurization effect, and has a simple structure and a small footprint. The air outlet pipe 201 is set in an L shape, and the air outlet pipe 201 is far from the small ring The direction of one end of the pipe 002 is opposite to the direction of the end of the intake pipe 101 away from the large annular pipe 001, so as to facilitate the discharge of flue gas after desulfurization treatment. The outer walls of the large annular pipe 001 and the small annular pipe 002 are both provided with an insulating layer 103 for heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com