High-formwork angle monitoring device capable of being quickly disassembled and assembled and monitoring method thereof

A technology of angle monitoring and high support formwork, applied in measuring devices, optical devices, surveying and navigation, etc., can solve the problems of easy falling off monitoring costs, reduce equipment usage, inconvenient disassembly and assembly, and achieve simple and labor-saving disassembly. The effect of reducing equipment usage and improving equipment usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

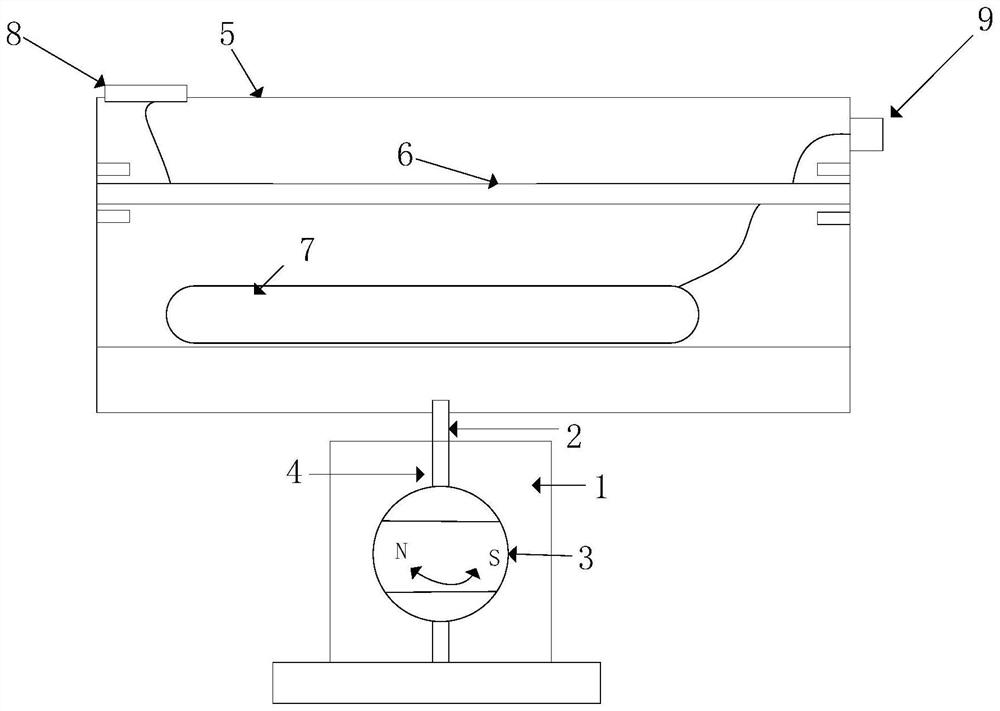

[0053] see figure 1 , the present embodiment provides a quick disassembly and assembly high formwork angle monitoring device, the monitoring device is used to monitor a high formwork and obtain relevant parameters of the high formwork. The surface of the monitoring device can be provided with a corrosion-resistant waterproof coating, so as to avoid the impact of the external environment of the high formwork on the monitoring device, especially to prevent rainwater and the like from damaging the device. Wherein, the monitoring device mainly includes a detection mechanism and a disassembly mechanism, and the two mechanisms are fixedly connected. Of course, in some embodiments, the monitoring device may also include some other mechanisms, which need to be set up according to actual needs.

[0054] The detection mechanism is used to detect the monitoring parameters of the high formwork. The monitoring parameters include the angle and level of the high formwork. In other embodimen...

Embodiment 2

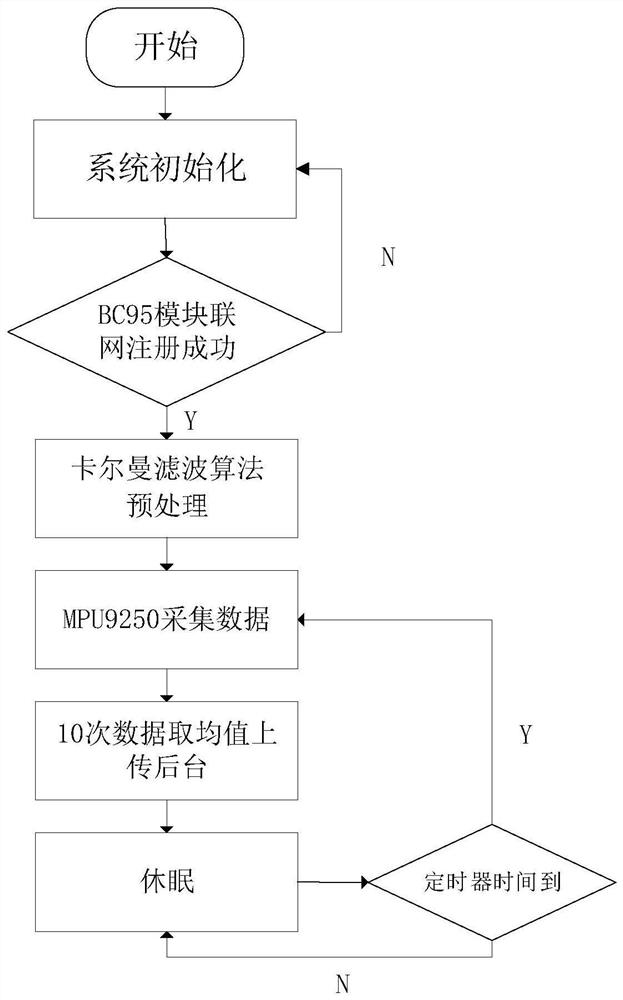

[0068] see figure 2 , this embodiment provides a quick disassembly high formwork angle monitoring device, on the basis of Embodiment 1, a controller is added to the device. Among them, the controller is used to first judge whether the detection mechanism is successfully registered in a remote background, and if so, it drives the detection mechanism to collect the data of the monitoring parameters, then performs Kalman filter processing on the data of the monitoring parameters, and finally converts the data after multiple filtering Take the average value and transmit it to the remote background. When the detection organization fails to register successfully, the controller continues to make the detection organization try to register until the registration is successful. Before each registration, the controller initializes the system. After the registration is successful, the controller will perform preprocessing through the Kalman filter algorithm, and then drive the MPU9250...

Embodiment 3

[0070] This embodiment provides a quick disassembly and assembly high formwork angle monitoring device, on the basis of Embodiment 1, a camera is added to the monitoring device. The camera belongs to a part of the detection mechanism, which is installed on the shell 5 and is used to take external images of the high-support formwork. The number of cameras is generally one, and sometimes the number of cameras can be set to be multiple in order to obtain a more comprehensive image with a high-end model. The images collected by the camera will be transmitted to the background through the BC95 module, and the user can visually check the situation of the high-branch formwork in the background, especially when the high-branch formwork is deformed, the deformed image can be found immediately, so that It is helpful to deal with the emergency situation of the high branch formwork and ensure the stability of the high branch formwork.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com