Bearing lubrication structure for screw blower or vacuum pump

A bearing lubrication and blower technology, which is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, can solve the problems of occupying the axial length space of the bearing, occupied, and multi-bearing axial space, etc. The effect of small space occupation, convenient manufacture and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

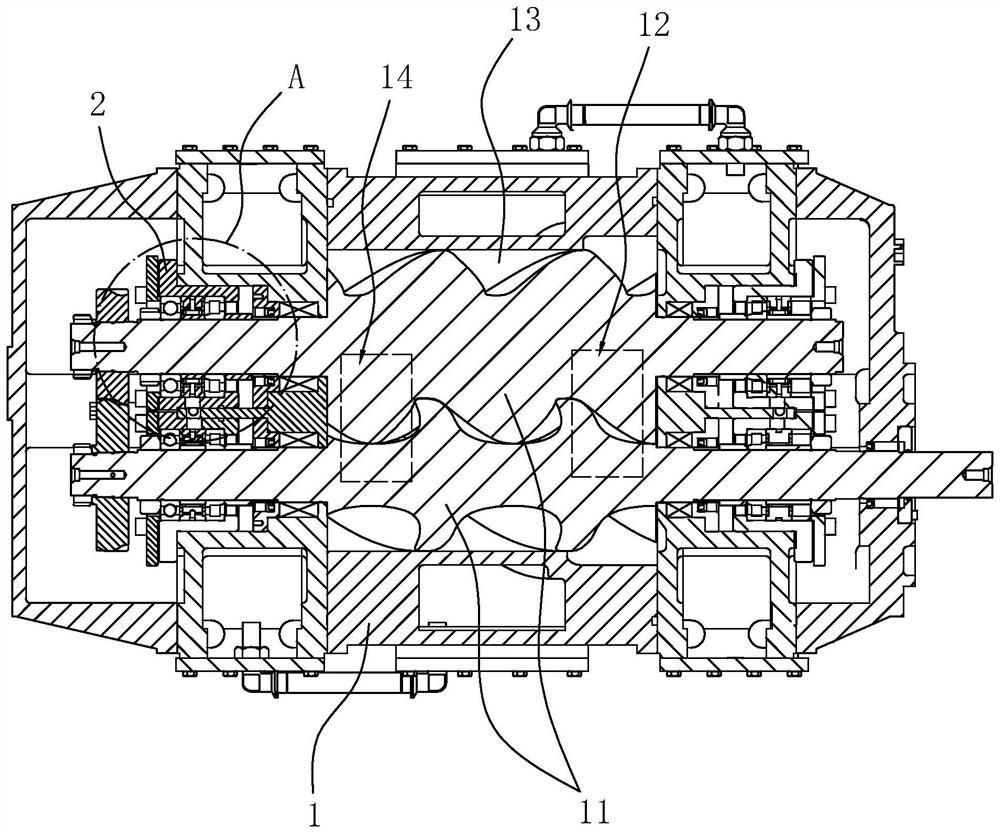

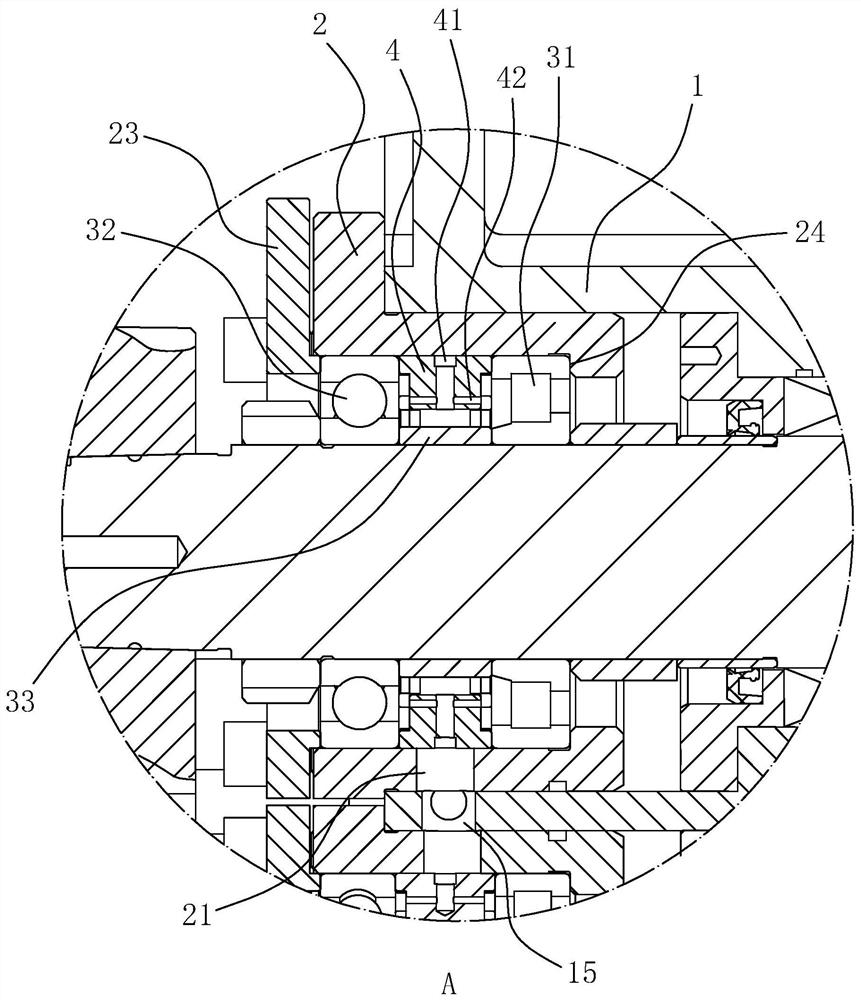

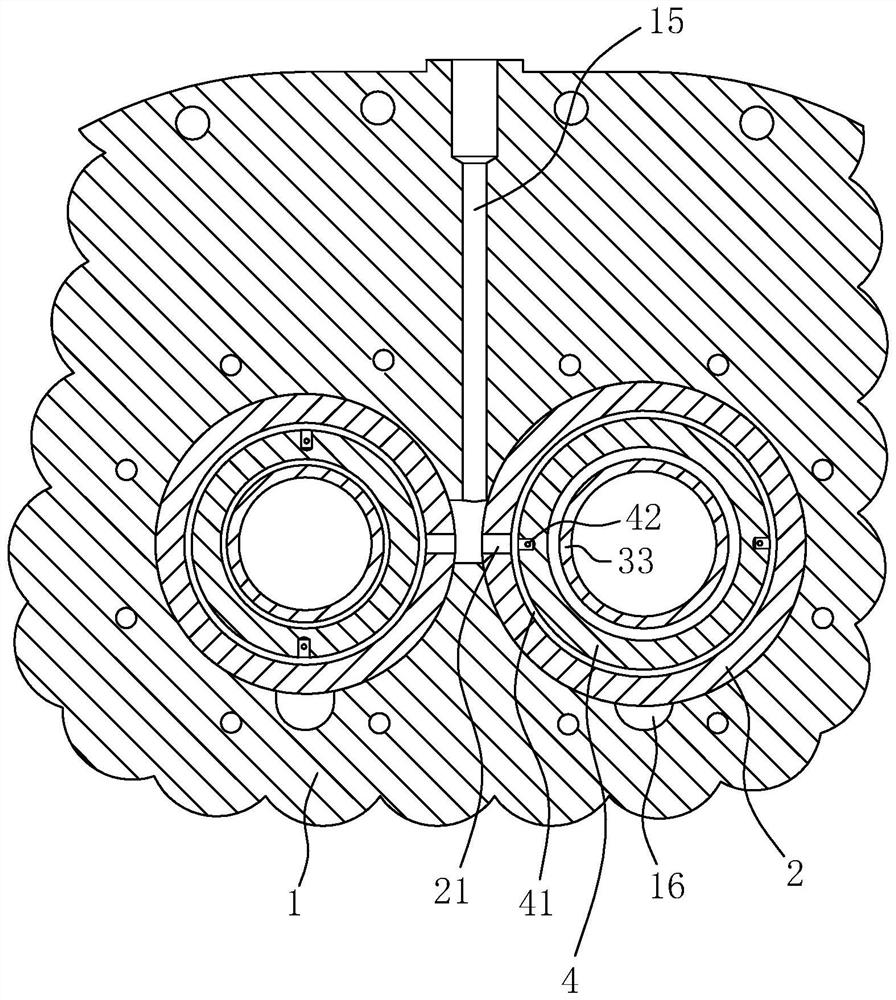

[0038] refer to figure 1 , is a bearing lubricating structure of a screw blower or a vacuum pump disclosed by the present invention, including a casing 1 and a bearing seat 2. Two screws 11 are arranged in parallel in the casing 1, and the rotating shafts of the two screws 11 are at the same height. The number of bearing seats 2 corresponds to the number of ends of the screw rods 11 , and the rotating shafts of the screw rods 11 penetrate into the bearing seats 2 in a one-to-one correspondence. The casing 1 is provided with an air inlet 12, a compression chamber 13, and an exhaust port 14 that communicate with each other. The compression chamber 13 is a working chamber for the screw 11 to rotate. The length direction of the compression chamber 13 is along the length direction of the screw rod 11. The end of 13 is the position close to the exhaust port 14, which is the compression end of the screw 11. When the screw blower or vacuum pump is running, the end of the compression c...

Embodiment 2

[0048] A bearing lubrication structure for a screw blower or a vacuum pump, the difference between Embodiment 2 and Embodiment 1 is:

[0049] refer to Figure 6 , the casing 1 is provided with a sliding hole 17, the sliding hole 17 is located above the oil inlet hole 21, the sliding hole 17 connects the oil inlet passage 15 with the end area of the compression chamber 13, the sliding hole 17 and the oil inlet passage 15 intersect to form a cross , the sliding hole 17 is provided with a spring 51 and a piston rod 52 for sliding, wherein the end of the piston rod 52 communicates with the compression chamber 13, the spring 51 is located on the side of the piston rod 52 away from the compression chamber 13, and the spring 51 is located in the sliding hole 17 bottom of the hole. The piston rod 52 establishes a sliding seal with the sliding hole 17 through the sealing ring. The side wall of the piston rod 52 is provided with a port 521 for oil supply to pass through. The sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com