Construction method and system for roof reinforcement system conversion of immersed tube prefabrication

A system conversion and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as roof reinforcement construction, and achieve the effects of high work efficiency, convenient operation, and reduced construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

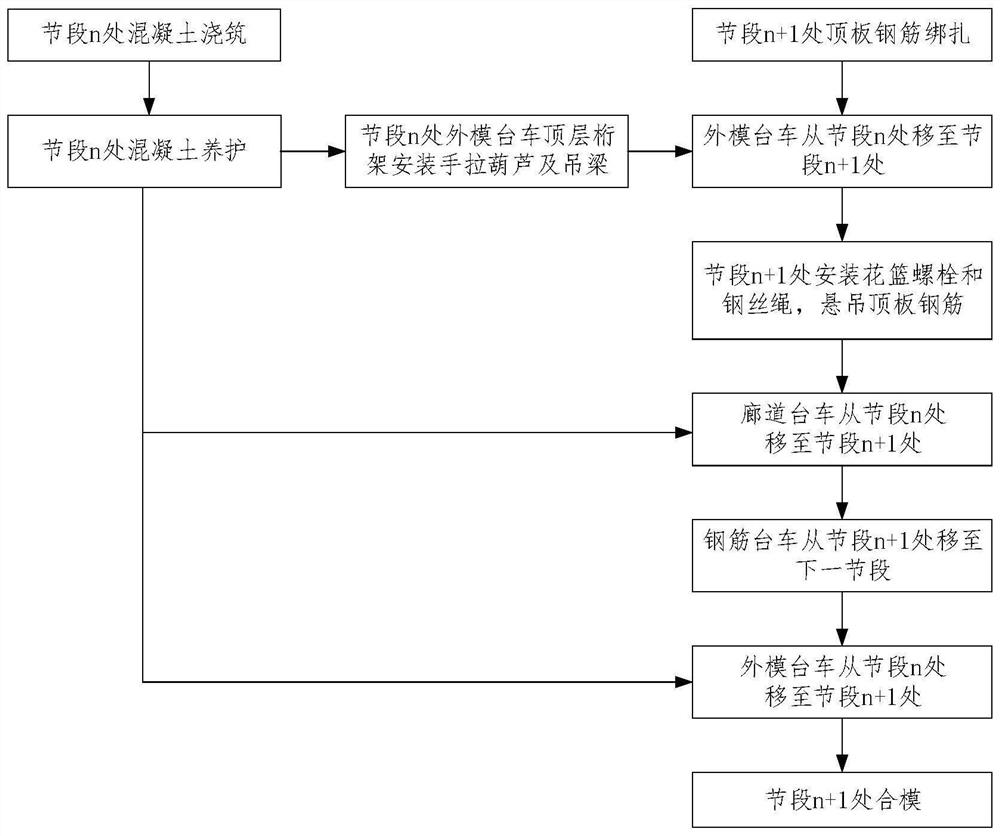

[0048] Such as figure 1As shown, the present invention provides a construction method for the transformation of steel bar system of immersed tube prefabricated roof. Self-expandable and self-propelled.

[0049] Include the following steps:

[0050] Step 1, such as Figure 4 and Figure 5 As shown, the construction content of segment n before the outer mold is demoulded

[0051] Step 1.1, Segment n+1 floor steel bar and vertical wall steel bar binding, after the bottom plate steel bar and vertical wall steel bar binding is completed, install the support frame 18 of the middle pipe gallery, the support frame 18 of the middle pipe gallery is made of section steel, and the support frame 18 of the middle pipe gallery The root is welded to the middle partition wall skeleton 19, and the center line of the support frame coincides with the center line of the immersed tube.

[0052] Step 1.2: After the binding of the steel bars on the bottom plate and the vertical wall of section n...

Embodiment 2

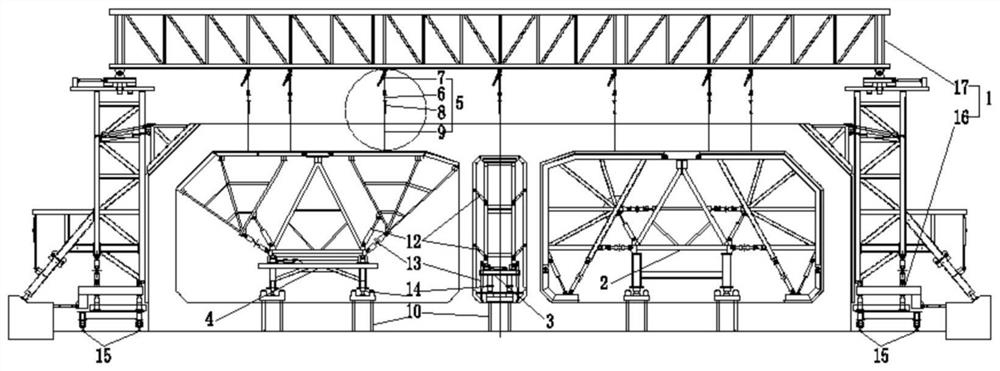

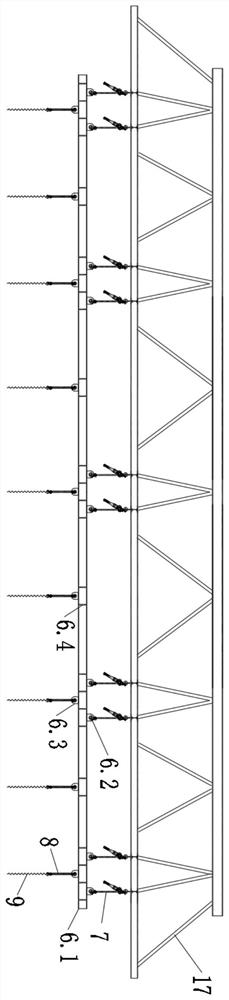

[0067] Construction systems for conversion of immersed tube prefabricated roof reinforcement systems, such as figure 2 and image 3 As shown, it includes: outer mold trolley 1, inner mold trolley 2, corridor trolley 3, reinforcement trolley 4 and spreader 5 for system conversion;

[0068] The inner mold trolley 2, the corridor trolley 3 and the reinforcement trolley 4 all adopt a walking mode, that is, they are pushed by their respective hydraulic systems, and their respective fixed legs 10 and movable legs 11 are mutually inverted. Way to walk, the inner mold trolley 2, corridor trolley 3 and reinforcement trolley 4 are all provided with a self-shrinkable support cylinder 12 and a self-shrinkable support screw 13.

[0069] Wherein the fixed support leg 10 and the movable support leg 11 walk in the way of mutual inversion, taking the inner mold trolley 2 as an example, specifically: 1. The movable support leg 11 oil cylinder lifts the cylinder, so that the movable support le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com