Paint for projection screen and preparation method thereof

A technology for projection screens and coatings, applied in fire-resistant coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve the problems of indoor darkening and low brightness, and achieve improved brightness coefficient, excellent performance, light reflectivity and The effect of both refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

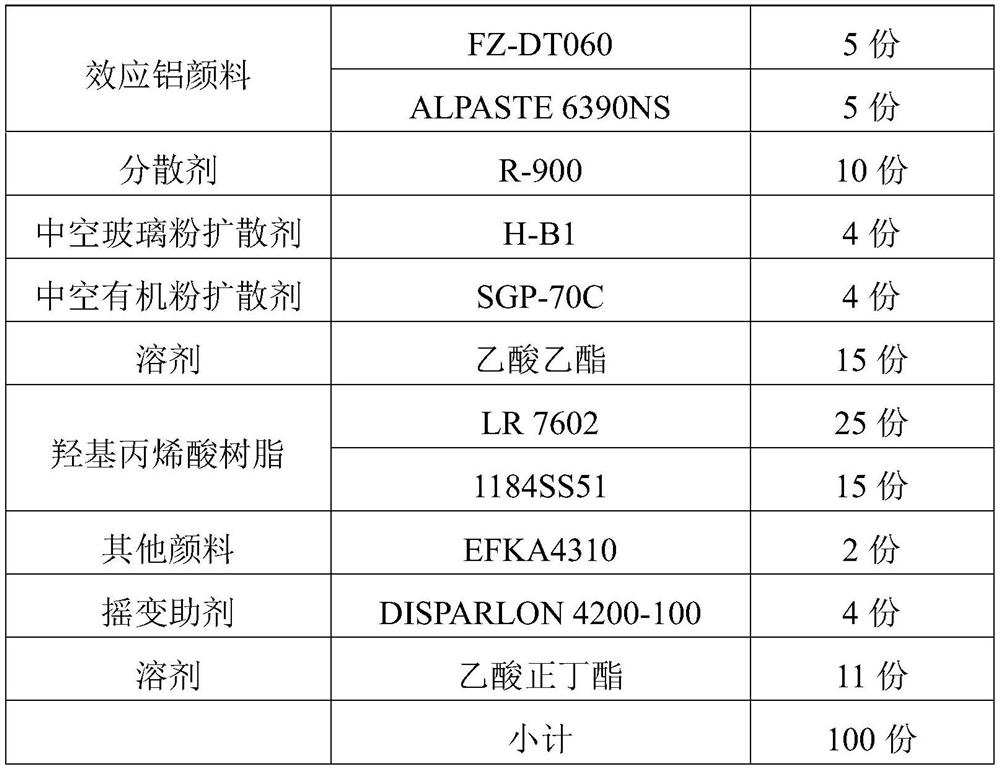

[0035] A coating composition for a projection screen, which is composed of a component A resin paint and a component B curing agent in a weight ratio of 100:25;

[0036] Wherein, the A component resin paint comprises the following components and parts by weight:

[0037]

[0038] The curing agent of the B component includes the following components and parts by weight:

[0039]

[0040] A method for preparing a coating composition for a projection screen specifically comprises the following steps:

[0041] (1) Add effect aluminum pigment, effect pearl powder, hollow glass powder diffusing agent, hollow organic powder diffusing agent, titanium dioxide and other pigments and dispersants and hydroxyl acrylic resin into the dispersion tank by weight, and stir evenly , then add relevant solvents, stir at low speed for 20-30min, and then stir at high speed for 25-35min, then import it into a sand mill disperser to grind and disperse to a fineness below 30μm, add thixotropic a...

Embodiment 2

[0045] A coating composition for a projection screen, which is composed of a component A resin paint and a component B curing agent in a weight ratio of 100:25;

[0046] Wherein, the A component resin paint comprises the following components and parts by weight:

[0047]

[0048] The curing agent of the B component includes the following components and parts by weight:

[0049]

[0050]

[0051] A method for preparing a coating composition for a projection screen specifically comprises the following steps:

[0052] (1) Add effect aluminum pigment, effect pearl powder, hollow glass powder diffusing agent, hollow organic powder diffusing agent, titanium dioxide and other pigments and dispersants and hydroxyl acrylic resin into the dispersion tank by weight, and stir evenly , then add relevant solvents, stir at low speed for 20-30min, and then stir at high speed for 25-35min, then import it into a sand mill disperser to grind and disperse to a fineness below 30μm, add t...

Embodiment 3

[0056] A coating composition for a projection screen, which is composed of a component A resin paint and a component B curing agent in a weight ratio of 100:25;

[0057] Wherein, the A component resin paint comprises the following components and parts by weight:

[0058]

[0059]

[0060] The curing agent of the B component includes the following components and parts by weight:

[0061]

[0062] A method for preparing a coating composition for a projection screen specifically comprises the following steps:

[0063] (1) Add effect aluminum pigment, effect pearl powder, hollow glass powder diffusing agent, hollow organic powder diffusing agent, titanium dioxide and other pigments and dispersants and hydroxyl acrylic resin into the dispersion tank by weight, and stir evenly , then add relevant solvents, stir at low speed for 20-30min, and then stir at high speed for 25-35min, then import it into a sand mill disperser to grind and disperse to a fineness below 30μm, add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com