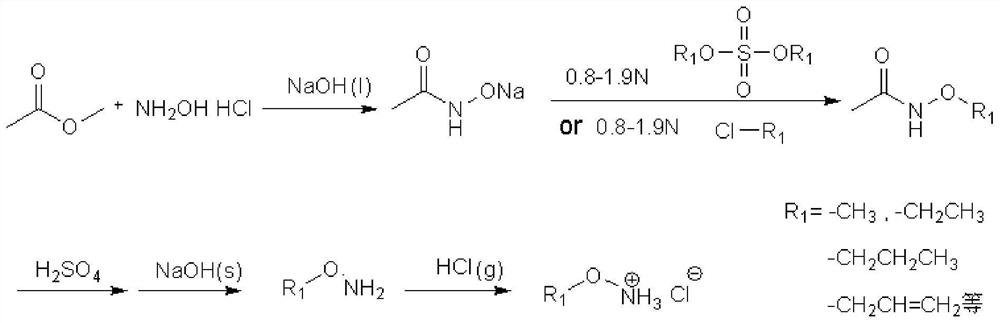

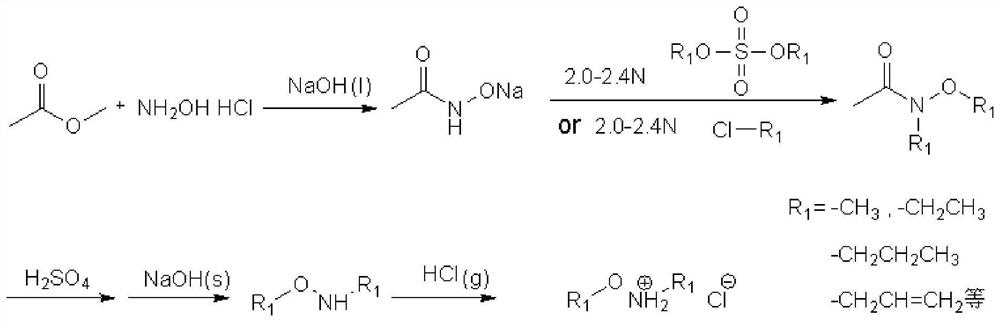

One-pot method for preparing O-alkyl hydroxylamine hydrochloride and N,O-dialkyl hydroxylamine hydrochloride

A technology of dialkylhydroxylamine hydrochloride and alkylhydroxylamine hydrochloride, which is applied in the field of preparing O-alkylhydroxylamine hydrochloride and N in one pot, can solve problems such as difficult industrialization, and achieve small molecular weight and few impurities , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of N, O-dimethylhydroxylamine hydrochloride

[0033]First mix 35.0g of hydroxylamine hydrochloride with 36.0g of water and 37.0g of methyl acetate, stir at 25°C, add dropwise 113.3g of 30% sodium hydroxide solution, add dropwise for 2 hours, and react for 1 hour. Add 160.0g dimethyl sulfate dropwise to the reaction kettle, and add dropwise 104.3g 50% sodium hydroxide solution at the same time. After passing the reaction for 5 hours, add 49g concentrated sulfuric acid dropwise and heat up to 76°C for hydrolysis for 5 hours. After passing the test, slowly Add 80 g of 50% liquid caustic soda to adjust the pH to 12, steam N, O-dimethylhydroxylamine under normal pressure, and collect fractions from 43 to 70°C. Acidify with hydrochloric acid gas, cool to crystallize, filter, wash twice with 20ml of cold ethanol, and dry to obtain 37.1g of N,O-dimethylhydroxylamine hydrochloride, yield 76.1%, white crystal, melting point 113.2-114.4°C, infrared T...

Embodiment 2

[0034] Embodiment 2: the preparation of N, O-diethylhydroxylamine hydrochloride

[0035] First mix 70.0g of hydroxylamine hydrochloride with 72.0g of water and 80.0g of methyl acetate, stir at 30°C, add dropwise 240.0g of 30% sodium hydroxide solution, add dropwise for 1 hour, and react for 3 hours. Add 323.4g of diethyl sulfate dropwise to the kettle, and add dropwise 200.5g of 50% sodium hydroxide solution at the same time. After the dropwise addition time is 2 hours, after the reaction is qualified, add 98.0g of concentrated sulfuric acid dropwise and raise the temperature to 80°C for 3 hours for hydrolysis, and the test is qualified Then slowly add 87.0 g of caustic soda to adjust the pH to 12, steam N, O-diethylhydroxylamine under normal pressure, and collect fractions from 60 to 90°C. Acidify with hydrochloric acid gas, cool and crystallize, filter and dry to obtain 98.2 g of N, O-diethylhydroxylamine hydrochloride, yield 78.2%, white crystal, melting point 123.4-125.2 °...

Embodiment 3

[0036] Embodiment 3: the preparation of N, O-dipropyl hydroxylamine hydrochloride

[0037] First mix 700.0g of hydroxylamine hydrochloride with 800.0g of water and 810.0g of methyl acetate, stir at 20°C, add 2200.0g of 40% sodium hydroxide solution dropwise, add dropwise for 2.3 hours, and react for 1.5 hours. Add 3075g, 1-bromopropane, add 400.0g sodium hydroxide flake alkali at the same time, reflux reaction for 8 hours, after passing the test, cool down, add 980.0g concentrated sulfuric acid dropwise and heat up to 60°C for hydrolysis for 7 hours, slowly add 1200.0 Adjust the pH to 12 with g caustic soda, steam N, O-dipropylhydroxylamine under atmospheric pressure, and collect fractions from 60 to 99°C. Acidify with hydrochloric acid gas, cool and crystallize, filter and dry to obtain 1246.5 g of N, O-dipropylhydroxylamine hydrochloride, yield 81.1%, white crystal, melting point 146.2-148.1 ° C, infrared spectrum consistent with the standard spectrum, water content 0.48 %,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com