A method for increasing the concentration of monodisperse carbon nanotube dispersion

A technology of carbon nanotubes and dispersion liquid, which is applied in the direction of carbon nanotubes, multi-walled carbon nanotubes, nanocarbons, etc., can solve the problem of difficult dispersion and preparation of monodisperse carbon nanotube solutions, reduce the separation efficiency and output of carbon nanotubes, etc. problems, to achieve efficient preparation and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

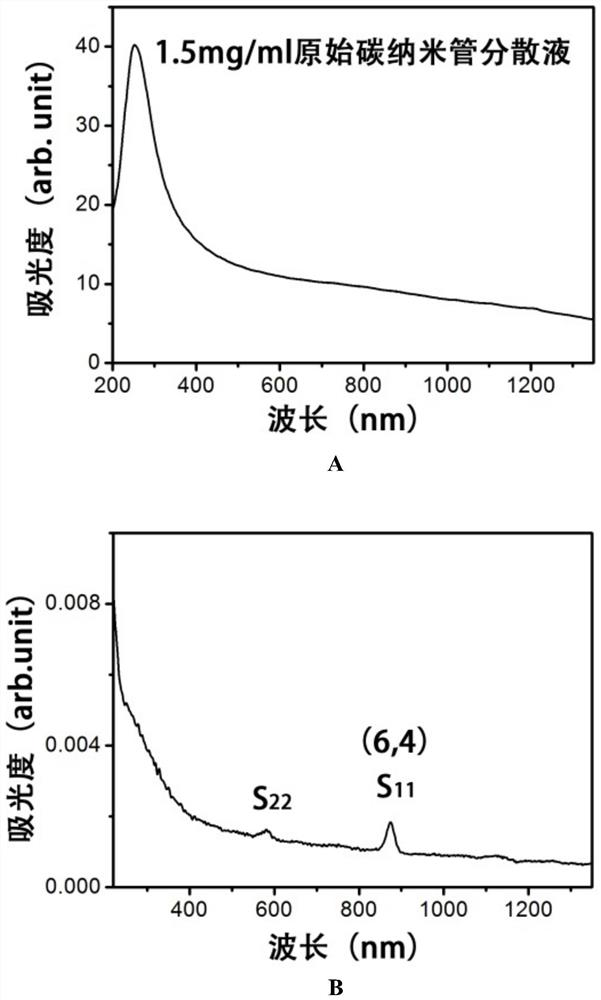

Embodiment 1

[0046] This embodiment is used to specifically illustrate the preparation method of a high-concentration carbon nanotube dispersion liquid with high dispersibility, wherein the specific steps are as follows Figure 8 shown in the flow chart.

[0047] 1) Weigh 200 mg of commercially available carbon nanotube powder (GNH series, Beijing North Guoneng Co., Ltd.) and 2 g of sodium dodecyl sulfate (SDS) powder, add them to 100 mL of water together, and use an ultrasonic breaker (Sonifire 450D, Branson ) at a power of 30W / cm 2 Ultrasonic dispersion of the above solution for 16 hours;

[0048] 2) Centrifuge to remove impurities such as metal catalyst particles, carbon nanotube bundles and amorphous carbon in the dispersion in step 1), set the centrifugal force to 210000g, and take 90wt% of the supernatant for 30 minutes;

[0049] 3) Ultrasonic dispersion is carried out on the upper dispersion liquid obtained in step 2), with a power of 30W / cm 2 , the above solution was dispersed i...

Embodiment 2

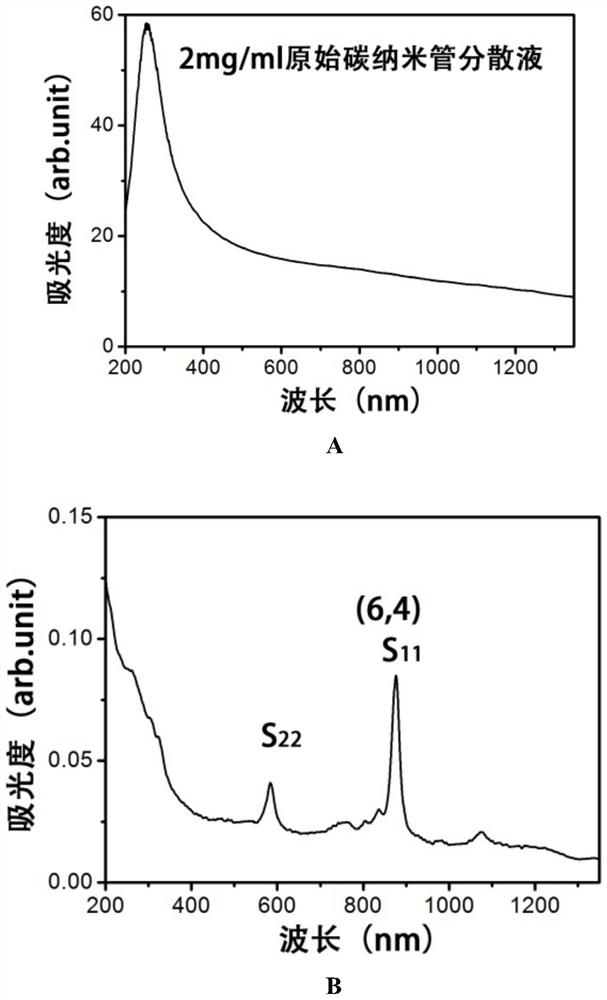

[0056] This example is used to specifically illustrate the dispersion conditions of the present invention for preparing a high-dispersion carbon nanotube dispersion liquid concentration.

[0057] 1) Weigh 6 mg of commercially available carbon nanotube powder (GNH series, Beijing North Guoneng Co., Ltd.), 0.004 g of sodium cholate and 0.012 g of sodium lauryl sulfate powder, add them to 4 mL of water together, and use an ultrasonic breaker ( Sonifire 450D, Branson) with a power of 2W / cm 2 Ultrasonic dispersion of the above solution for 120 minutes;

[0058] 2) Centrifuge to remove impurities such as metal catalyst particles, carbon nanotube bundles, and amorphous carbon in the dispersion in step 1), set the centrifugal force to 1,050,000 g for 2 minutes, remove the solid precipitation at the bottom, and take all the upper layer;

[0059] 3) Ultrasonic dispersion is carried out on the upper dispersion liquid obtained in step 2), power 2W / cm 2 , ultrasonically disperse the abov...

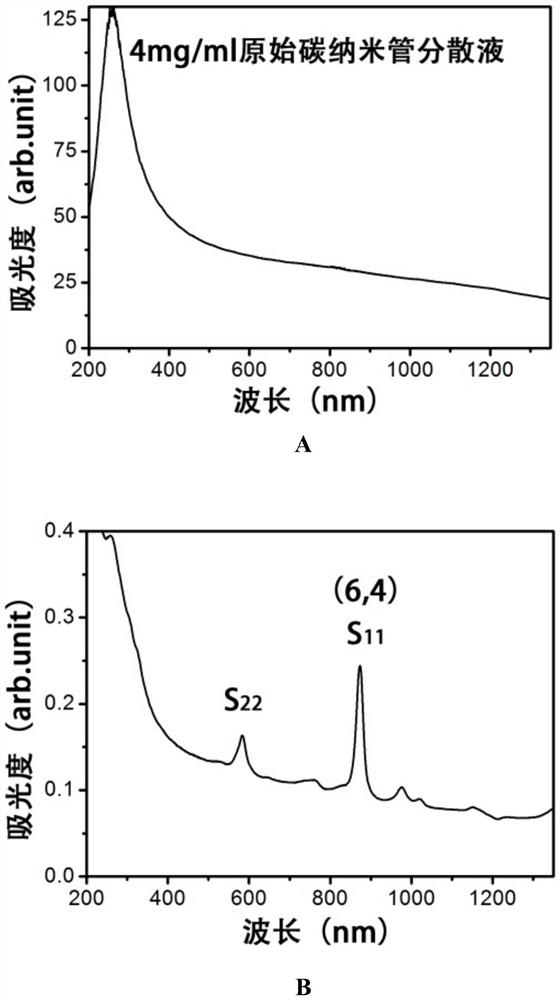

Embodiment 3

[0063] This example is used to specifically illustrate the end value of the concentration of the carbon nanotube dispersion liquid with high dispersibility and the corresponding dispersion conditions of the present invention.

[0064] 1) Weigh 400 mg of commercially available carbon nanotube powder (GNH series, Beijing North Guoneng Co., Ltd.) and 2 g of sodium lauryl sulfate powder, add them to 100 mL of water together, and use an ultrasonic breaker (Sonifire 450D, Branson) to 30W / cm 2 Ultrasonic dispersion of the above solution for 32 hours;

[0065] 2) Centrifuge to remove impurities such as metal catalyst particles, carbon nanotube bundles and amorphous carbon in the dispersion in step 1), set the centrifugal force to 210000g, and take 90wt% of the supernatant for 30 minutes;

[0066] 3) Ultrasonic dispersion is carried out on the upper dispersion liquid obtained in step 2), with a power of 30W / cm 2 , ultrasonically disperse the above solution for 3 hours;

[0067] 4) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com