H grade cti600 epoxy glass cloth laminated board and its production method

A technology of epoxy glass cloth and production method, which is applied in glass/slag layered products, lamination, layered products, etc., can solve the problem of insufficient thermal stability of prepreg, poor insulation of substrate, and low resistance to tracking voltage. and other problems, to achieve the effect of reducing uneven glue, high anti-tracking voltage and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

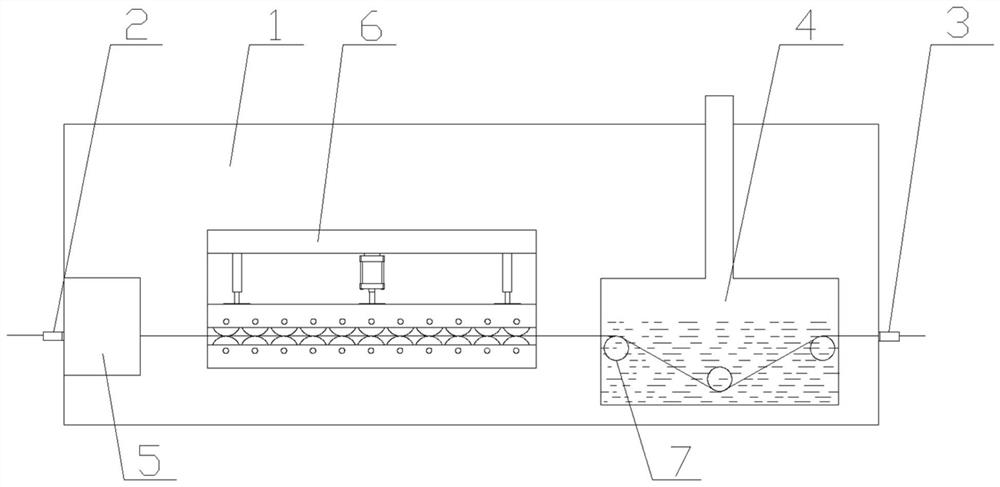

Image

Examples

Embodiment 1

[0175] 1. Glue formula:

[0176]

[0177] 2. Control parameters of the prepreg:

[0178] drying temperature Dipping speed Resin content Dipping time mobility Volatile 170℃ 16m / min 41% 100s 21% 0.3%

[0179] When the glass cloth is dipped, the vacuum-assisted gluing method is adopted;

[0180] 3. Hot pressing parameters:

[0181] The first pressure parameters are:

[0182] Hot pressing temperature pressure Hot pressing time 180℃ vacuum hot pressing 30kg / cm 2

45min

[0183] The second pressure parameters are:

[0184] Hot pressing temperature pressure Hot pressing time 150℃ vacuum hot pressing 10kg / cm 2

Embodiment 2

[0186] 1. Glue formula:

[0187]

[0188] 2. Control parameters of the prepreg:

[0189] drying temperature Dipping speed Resin content Dipping time mobility Volatile 180℃ 18m / min 45% 97s 23% 0.35%

[0190] When the glass cloth is dipped, the vacuum-assisted gluing method is adopted; 3. Hot pressing parameters:

[0191] The first pressure parameters are:

[0192] Hot pressing temperature pressure Hot pressing time 178℃ vacuum hot pressing 43kg / cm 2

61min

[0193] The second pressure parameters are:

[0194] Hot pressing temperature pressure Hot pressing time 142℃ vacuum hot pressing 20kg / cm 2

Embodiment 3

[0196] 1. Glue formula:

[0197]

[0198]

[0199] 2. Control parameters of the prepreg:

[0200] drying temperature Dipping speed Resin content Dipping time mobility Volatile 200℃ 20m / min 42% 95s 24% 0.37%

[0201] When the glass cloth is dipped, the vacuum-assisted gluing method is adopted;

[0202] 3. Hot pressing parameters:

[0203] The first pressure parameters are:

[0204] Hot pressing temperature pressure Hot pressing time 175℃ vacuum hot pressing 50kg / cm 2

100min

[0205] The second pressure parameters are:

[0206] Hot pressing temperature pressure Hot pressing time 135℃ vacuum hot pressing 25kg / cm 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com