Base plate and packaging structure

A substrate and substrate surface technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as product failure, large substrate warpage, and semiconductor product damage, and avoid delamination of packaging glue and substrate , Guarantee the placement quality, and suppress the effect of substrate warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

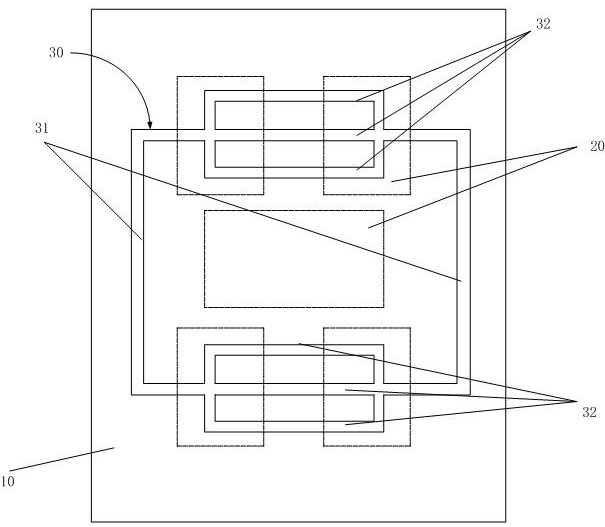

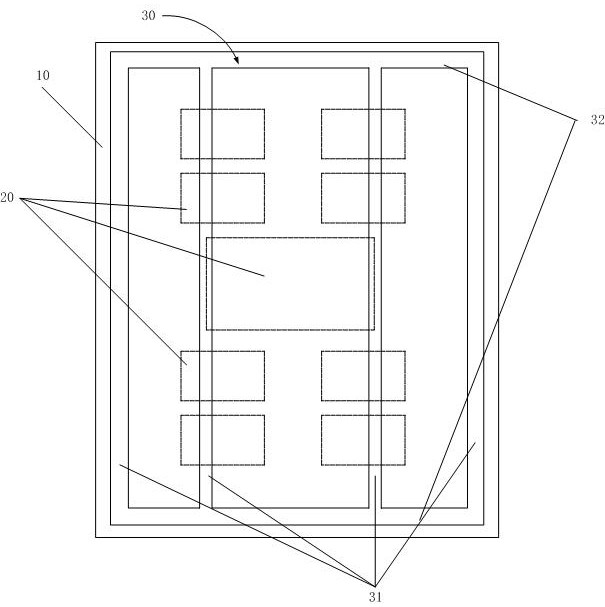

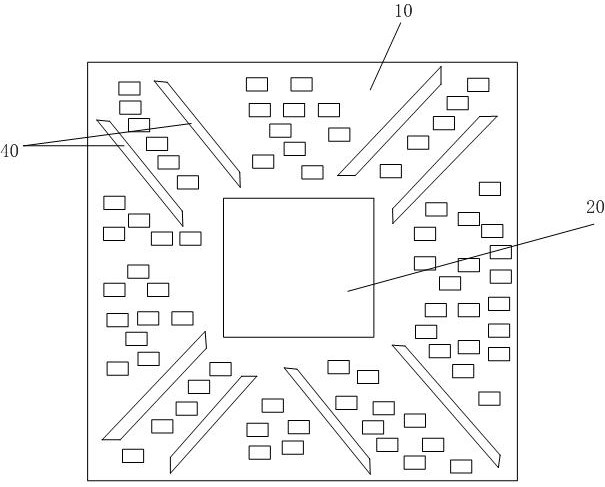

[0026] The application will be further described in detail below with reference to the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the related invention, but not to limit the invention. In addition, it should be noted that, for ease of description, only the parts related to the invention are shown in the drawings.

[0027] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present application will be described in detail with reference to the drawings and in conjunction with embodiments.

[0028] reference Figure 5 The package structure includes a substrate 100 and a chip 200 and passive components arranged on the substrate carrying surface. The substrate 100 has an interconnected metal conductive layer, and the conductive layer connecting the chip 200 and the passive component is exposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com