Sealing structure and method for refrigerating rotor compressor

A sealing structure and rotor sealing technology, applied in the field of rotor compressors, can solve the problems of inability to use rolling rotor compressors, increase the difficulty of assembly and processing, increase the frictional resistance of the end face, etc. Consistent performance and improved efficiency, reduced friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

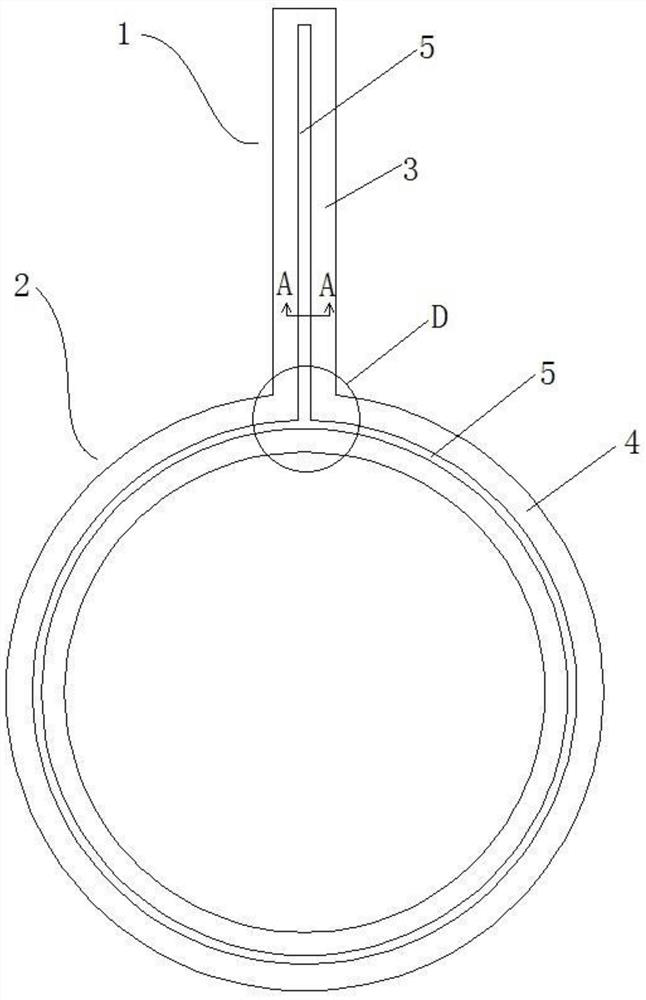

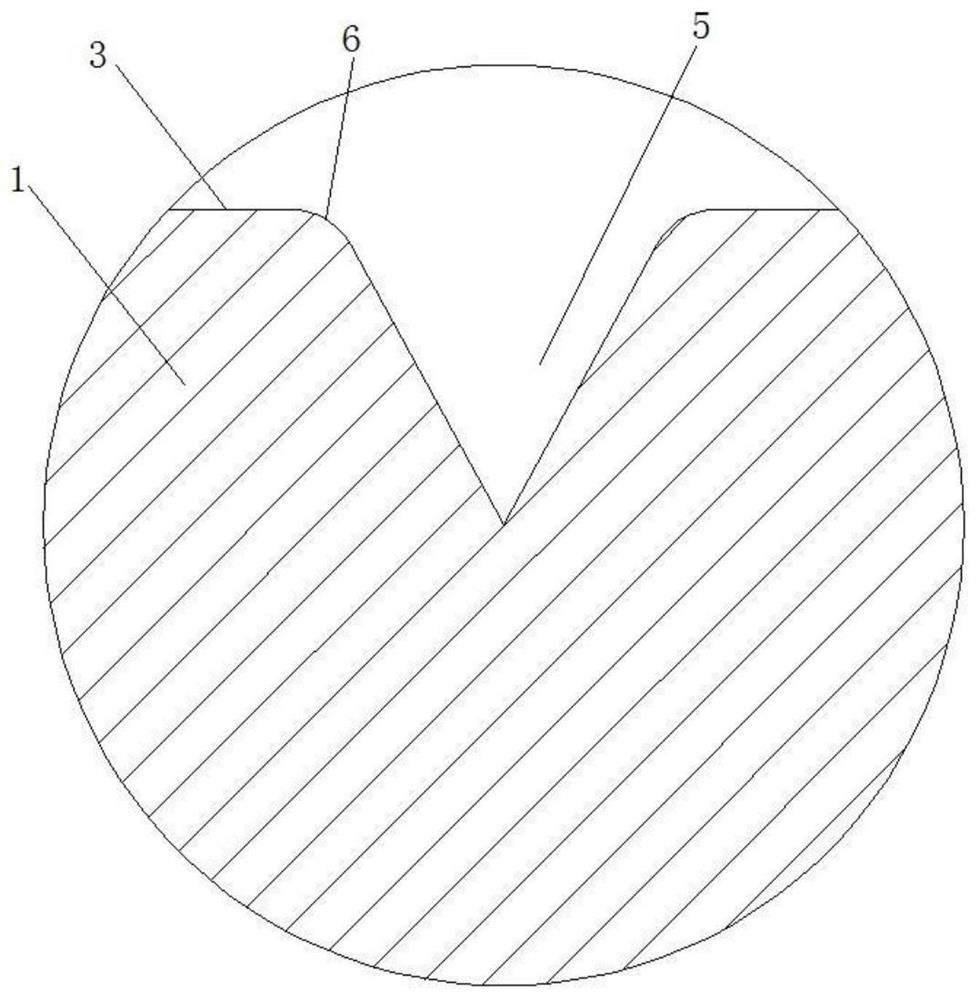

[0052] Such as figure 1 As shown, a sealing structure for a refrigeration rotary compressor, the rotary compressor has a rotor 2 and a slider 1 integrally formed; the slider 1 and the same side of the rotor 2 have sliders respectively The sealing end face 3 and the rotor sealing end face 4, the sealing structure is to set an oil groove 5 in the middle of the slider sealing end face 3 and the rotor sealing end face 4, the oil groove 5 contains the oil film, and the oil groove 5 contains a small amount Oil.

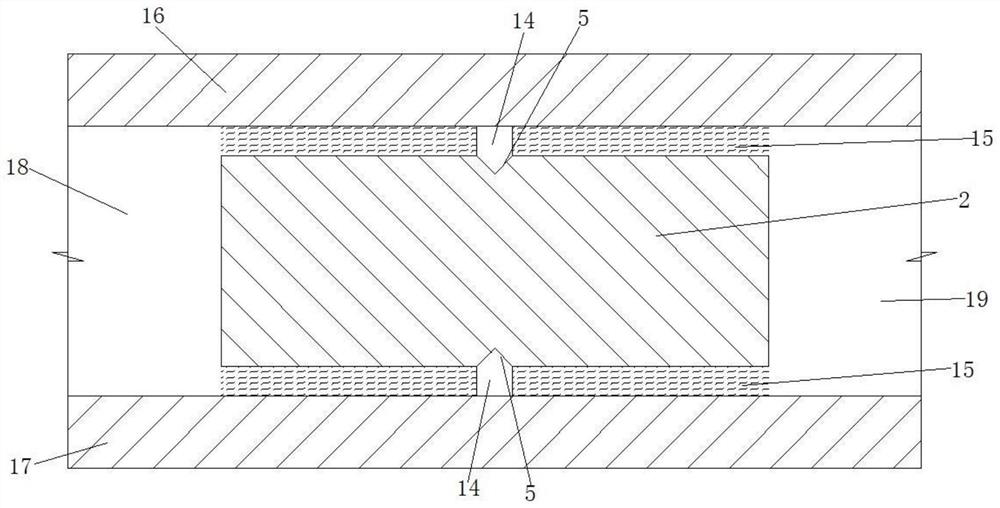

[0053] Specific design cases, such as figure 2 As shown, it is a partially enlarged schematic diagram of the oil tank 5 containing the oil film 15 in a certain state. The rotor 2 forms rotor sealing end faces between the upper end cover 16 and the lower end cover 17 of the compressor respectively. The left and right sides of the rotor 2 They are the suction cavity and the exhaust cavity respectively, and there is an air pressure difference between the suction cavity and ...

Embodiment 2

[0064] The difference between this embodiment and the first embodiment is that the shape of the oil groove is different.

[0065] specific as Image 6 As shown, the slope of the oil groove 5 on the sealing end surface 3 of the slider near the suction end is smaller than the slope near the exhaust end.

[0066] The slopes of the two side walls of the oil groove 5 are set to be different, which can change the tendency of the oil in the oil groove 5 to form an oil film, and the slope near the suction end (i.e. the high pressure end) side is smaller, which is conducive to the formation of an oil film this time. To counteract the oil film blown away by high-pressure gas.

[0067] Such as Figure 7 As shown, it is an arc-shaped oil groove 5. The arc-shaped oil groove 5 has no sharp corners and sharp corners. During the long-term reciprocating motion, the phenomenon of stress concentration is less, which is more conducive to maintaining the structural stability of the rotor and sli...

Embodiment 3

[0069] The difference between this embodiment and the first embodiment is that an oil storage structure is provided.

[0070] specific as Figure 8 As shown, the bottom of the oil tank 5 is also provided with an oil storage structure 7; the oil storage structure 7 is a through groove corresponding to and communicating with the oil groove 5, and the through groove is circular.

[0071] The oil storage structure 7 can store more oil to continuously replenish the lost oil film, reducing the frequency of oil replenishment and prolonging the use time;

[0072] Adopting the structure of the through groove, on the one hand, it can be processed and shaped; on the other hand, it can ensure the correspondence and communication with each section of the oil groove, forming a uniform oil supply, and will not cause oil accumulation in some areas and less oil in some areas Case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com