Fully assembled recyclable enclosure wall and construction method

A technology of full assembly and enclosure, applied in the parts of lighting devices, fences, lighting devices, etc., can solve the problems of difficult construction and installation, impossible construction, long construction period, etc., to meet the needs of use, facilitate hoisting construction, and construction efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical scheme and advantages of the present invention clearer, the following will be combined with the attached Figure 1-4 Embodiments of the present invention are further described in detail.

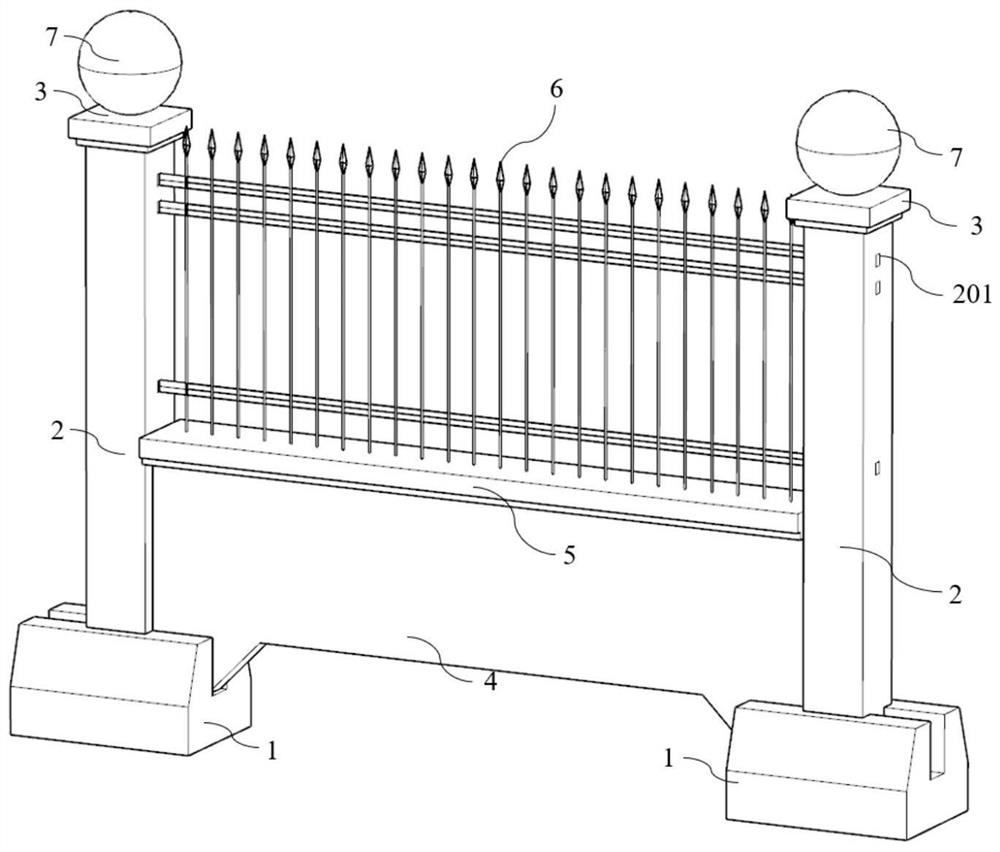

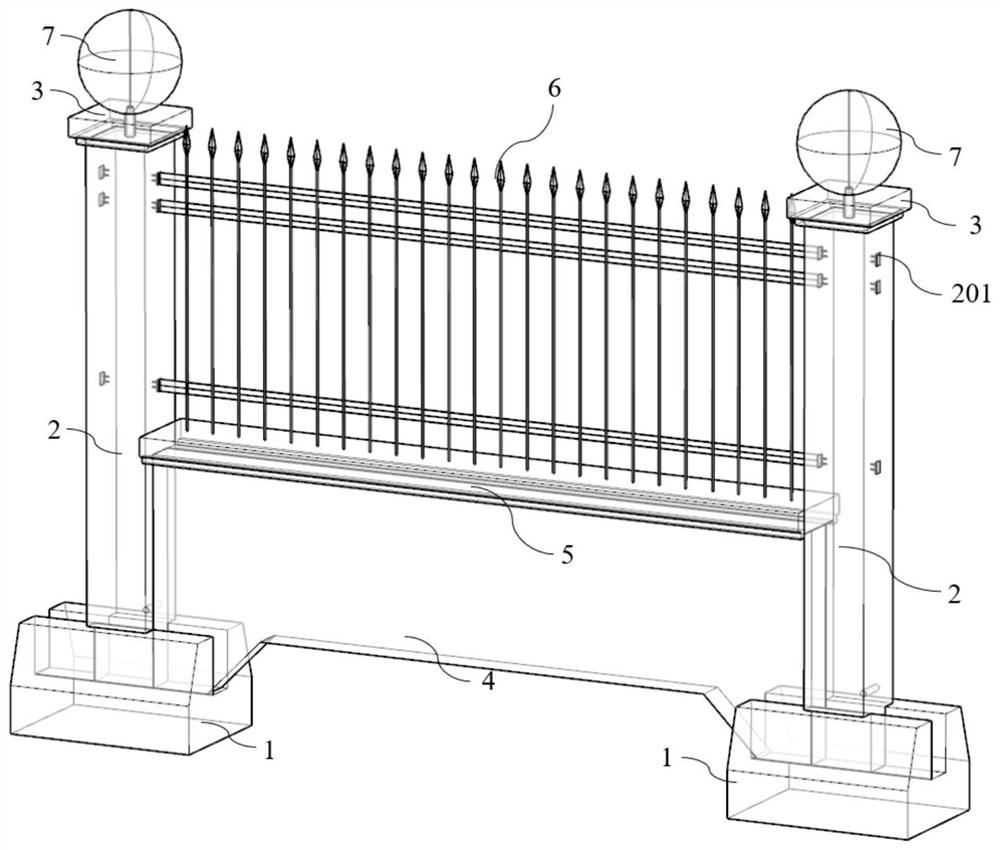

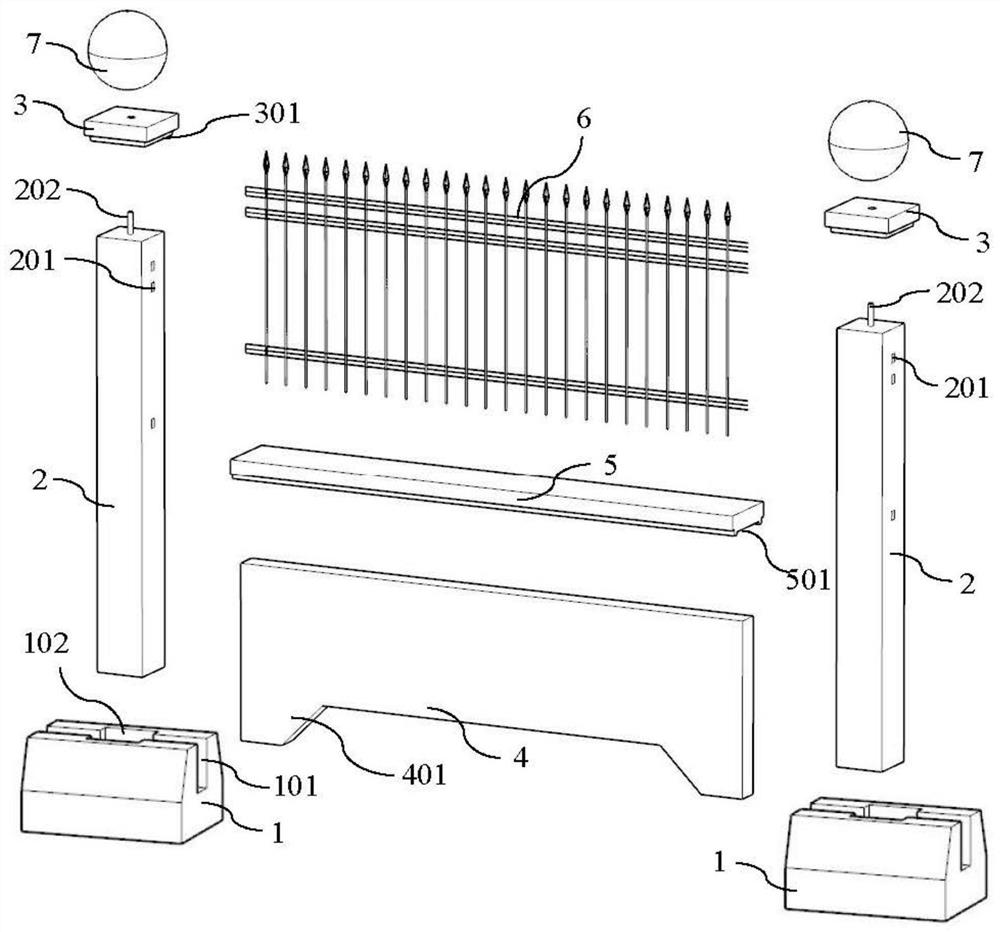

[0049] see Figure 1-Figure 3 The fully-assembled recyclable wall provided by the preferred embodiment of the present invention includes a PC component base 1, a PC component column 2, a PC component column cover 3, a PC component wall wall 4, a PC component wall wall cover 5, Fence fence 6, fence lighting 7.

[0050] Depend on figure 2 , image 3 As shown, the PC component base 1 of the present invention is horizontally provided with a square groove 101 connected at both ends, and the center position of the square groove 101 extends longitudinally to both sides to form a square hole groove 102; specifically, the PC component The appearance size of the base 1 is: 1000mm*700mm*550mm; the size of the square groove 101 in the top view and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com