Gallium ferrite nanofiber, manufacturing method and application of gallium ferrite nanofiber

A technology of nanofibers and manufacturing methods, which is applied in the field of gallium ferrite, can solve problems affecting the ferroelectric properties of materials, and achieve the effect of convenient operation, simple device, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

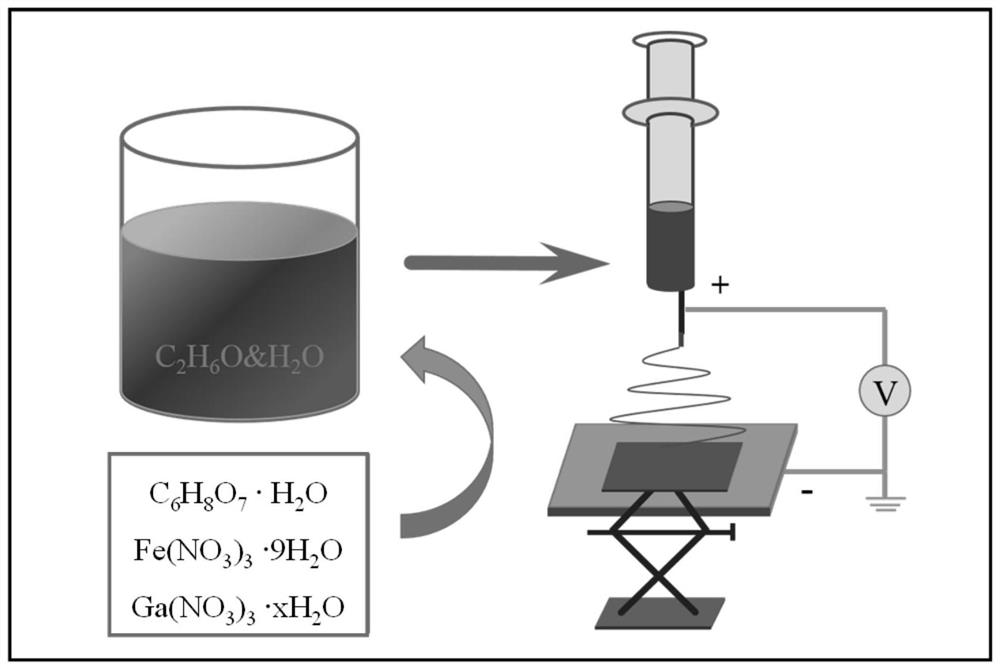

[0073] The second embodiment of the present invention discloses a method for producing a ferrous gallium ferrium nanofiber, comprising the steps of:

[0074] Step 1, a ferroacemonic acid solution is prepared using a sol gel method;

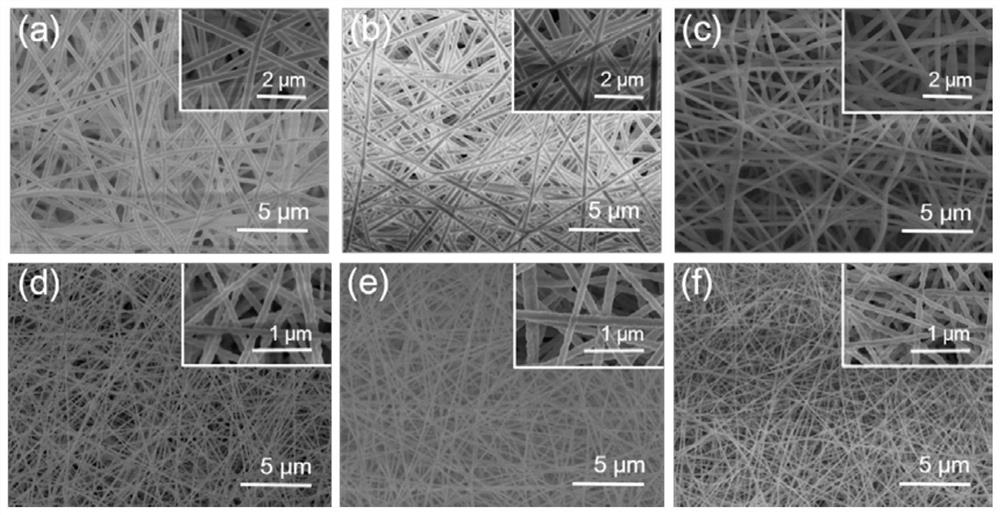

[0075] Step 2, the sufficiently aging iron gallium agglomerate solution is electrostatically spun, obtain a ferroelectric somatic fiber wire having a diameter of the first fiber structure;

[0076] Step three, the ferrous gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium gallium nanofibers are obtained, and the ferrous gallium nanofibers have room temperature monologue multi iron ferroelectric and ferromagnetic properties and have second. The fiber structure diameter is smaller than the diameter of the first fiber structure, and the second fiber structure of the ferrous nanofiber is 300 nm or less.

[0077] Preferably, the second fiber structure diameter relative to the first fiber structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com