Preparation system and method of solid fuel for cement clinker production

A cement clinker and solid fuel technology, which is applied in the field of solid fuel preparation system for cement clinker production, can solve the problems of difficult utilization of gasified fly ash and high cost of fuel preparation, achieve effective utilization, reduce coal consumption, Easy to Build Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

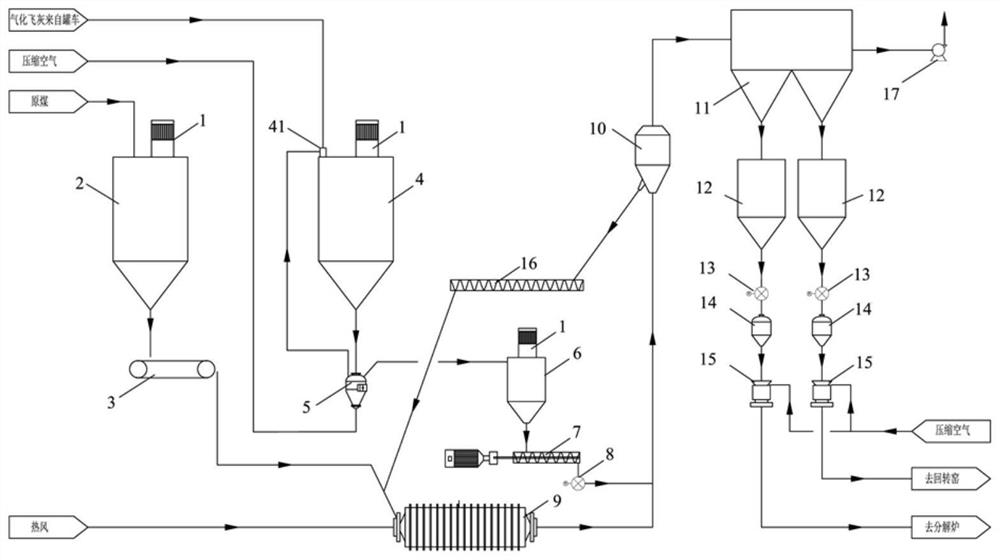

[0035] Such as figure 1 As shown, a solid fuel preparation system for cement clinker production includes a raw coal feeding device, which transports the raw coal to the coal grinding device; the raw coal feeding device is connected to the coal grinding device, and the coal grinding device Raw coal is ground into coal powder; the outlet of the coal grinding device is connected to the inlet of the fuel delivery device through the separation device, and the preparation system also includes a gasification fly ash feeding device, which is connected to the fuel delivery device through the separation device The device is connected, the raw coal and gasification fly ash are fully mixed and separated in the separation device, and the mixture obtained meets the fuel standard required for cement clinker production, and then is transported to the rotary kiln or calciner and other fuel-requiring facilities through the fuel delivery device. place to go. The system mixes gasified fly ash an...

Embodiment 2

[0048] Basically the same as in Example 1, in this implementation, a variable frequency star feeder 8 is also set between the screw feeder 7 and the pipeline, and the gasified fly ash is quantitatively transported to the frequency conversion star feeder through the screw feeder 7 8, and then through the secondary quantitative delivery of the frequency conversion star feeder 8 to the pipeline passing through the cyclone separator 10, the amount of gasified fly ash entering the pipeline is stable and accurate, and it is convenient to fully mix with coal powder. Furthermore, the top of the gasification fly ash bin 4 is provided with a collector 41, and the gasified fly ash produced by coal gasification enters into the gasification fly ash bin 4 through the collector 41 to ensure that the gasification fly ash enters the gasification fly ash bin 4. The sealing performance of the process of the gasification fly ash bin 4 avoids environmental pollution and waste caused by the leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com