Die-casting forming device for superhard grinding wheel with ordered microgroove structure

A die-casting forming and grinding wheel technology, which is applied in the field of die-casting forming devices for superhard grinding wheels with ordered micro-grooves, can solve the problem that it is difficult to realize grinding wheels with ordered micro-grooves structure on the surface, and cannot detect and control the damage of abrasive particles in real time and the distribution of abrasives in the grinding wheel. Unequal problems, to achieve the effect of improving grinding quality and grinding efficiency, strong process repeatability, and uniform abrasive distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

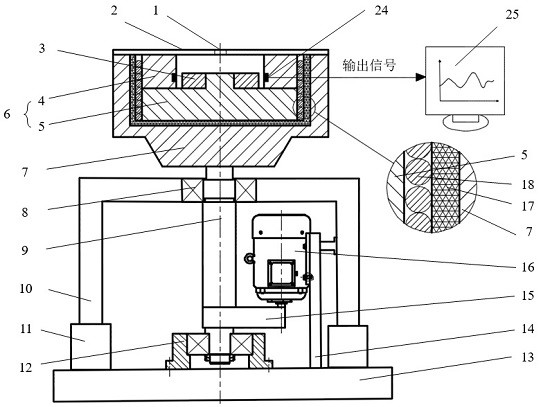

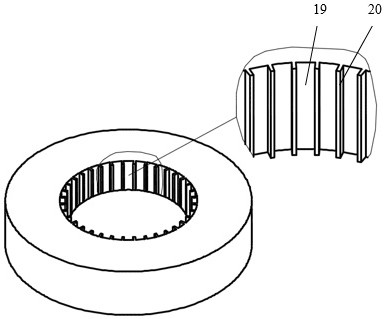

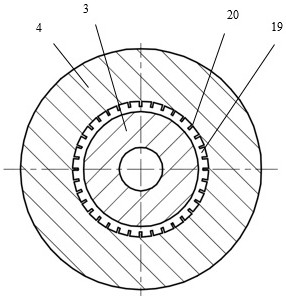

[0027] Such as Figure 1 to Figure 5 As shown, a die-casting device for a superhard grinding wheel with an ordered micro-groove structure is composed of a mold forming mechanism, a centrifugal die-casting mechanism and a temperature control system; the mold forming mechanism includes a mold 6 and a pressing plate 2; the mold 6 includes an upper mold 4 and the lower mold 5, a large number of thin slices are evenly distributed on the inner circumference of the upper mold 4, that is, the mold flakes 20, and the mold grooves 19 are formed between the mold flakes, and the mold grooves 19 correspond to the emery wheel 23 abrasive layer protrusions. The position of the block 21; the mold sheet 20 corresponds to the position of the abrasive layer groove 22; the center of the lower mold 5 protrudes and cooperate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com