Solid hydrogen storage tank

A hydrogen storage tank and hydrogen storage technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, ship construction details, etc., can solve the problem of poor heat transfer performance of the hydrogen storage material bed, annular porous mass transfer It is difficult to fill the modules evenly and affect the life and safety of the tank, which is beneficial to batch preparation, improves the performance of hydrogen charging/discharging, and improves the service life and safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

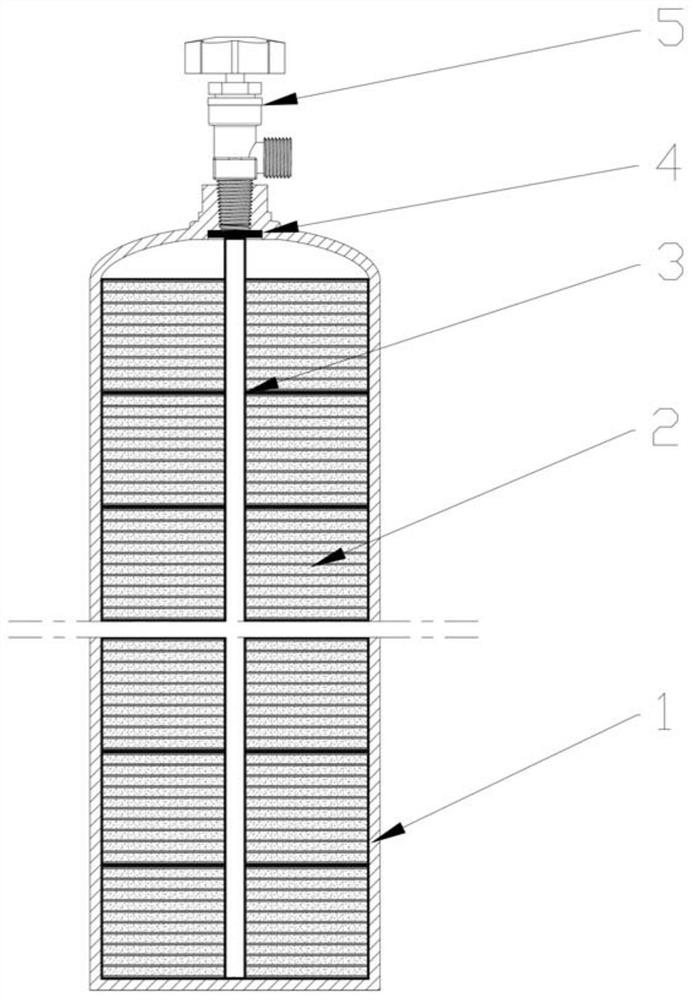

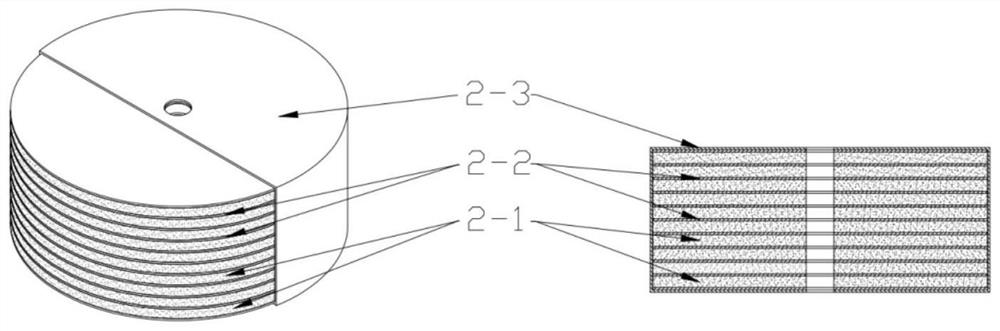

[0045] figure 1 A solid hydrogen storage tank according to Embodiment 1 of the present invention is shown, wherein the size of the tank body 1 is: outer diameter 70mm, wall thickness 3mm, length 425mm, and 10 hydrogen storage bed elements 2 and 1 airway3. Such as figure 2 As shown, the size of the hydrogen storage bed element 2 is: an outer diameter of 64 mm and a thickness of 42 mm. There is a through hole with a diameter of 8 mm in the center of the hydrogen storage bed element 2, and a total of 10 layers of storage tanks are placed in the hydrogen storage bed element 2. Hydrogen material layer 2-1, each layer placed 45g (TiZr) 1 (VFeMn) 2 Hydrogen storage material powder, the heat conduction layer 2-2 is aluminum foil with a diameter of 63 mm and a thickness of 0.3 μm, a total of 11 pieces; the flexible wrapping layer 2-3 is a 200-mesh brass mesh; the size of the air guide tube 3 is: The outer diameter is 8 mm, the total length is 420 mm, and the filtration precision i...

Embodiment 2

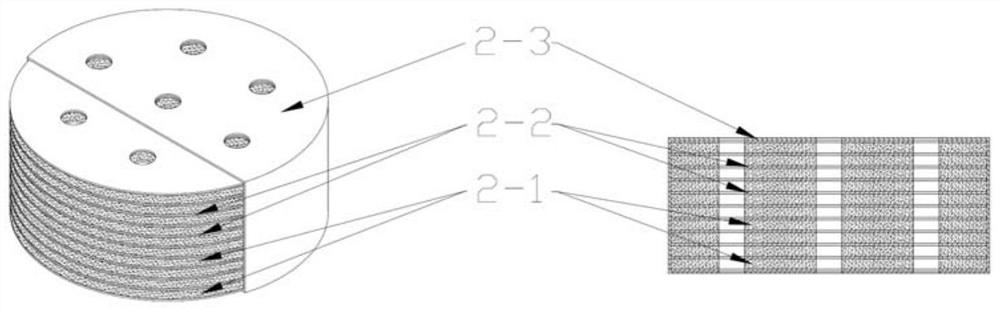

[0049] figure 1 It shows another solid hydrogen storage tank of the present invention, wherein the size of the tank body 1 is: outer diameter 133mm, wall thickness 4mm, length 1350mm, and 28 hydrogen storage bed elements 2 are placed in the tank body 1 . Such as figure 2 As shown, the size of the hydrogen storage bed element 2 is: outer diameter 125mm, thickness 46mm, the hydrogen storage bed element 2 is provided with 7 through holes with a diameter of 10mm, and one through hole is arranged in the center, 6 through holes are evenly distributed on the circumference with a radius of 40mm; a total of 15 layers of hydrogen storage material layers 2-1 are placed in the hydrogen storage bed element 2, and 135g (TiZr) is placed in each layer 1 (VFeMn) 2 Hydrogen storage material powder, thermal conduction layer 2-2 is a thin copper disc with a diameter of 122 mm and a thickness of 1 mm, a total of 16 pieces, and the flexible wrapping layer 2-3 is a 100-mesh copper mesh. The siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com