Marine water pump test device

A test device and water pump technology, which is applied to the components of the pumping device for elastic fluid, pump testing, pump components, etc., can solve the problem of increased logistics, management and operation costs, high failure rate of torque meters, pollution of workshop environment, etc. problems, to achieve the effect of saving storage space, reducing processes, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

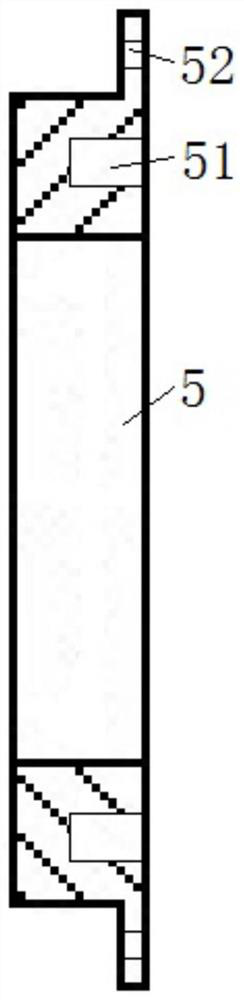

[0031] As a preferred embodiment of the present invention, three driving cylinders 61 are fixed on the side of the sliding seat 6 close to the water pump 10 to be tested, and the three driving cylinders 61 are evenly distributed in a concentric circle centered on the center hole of the sliding seat 6. circle on. The end of the piston rod 62 of the drive cylinder 61 is fixedly connected with the pressing plate 63. The pressing plate 63 is provided with three second mounting holes 65 connected with the first flange 71. The middle part of the pressing plate 63 is provided with A through hole, one end of the through hole communicates with the rigid water inlet pipe 7 , and the other end communicates with the water inlet hole of the first flange 71 . For the same product, after the water pump 10 to be tested is fixed on the mounting plate 5, the positive action button is activated, and the piston rod 62 of the drive cylinder 61 stretches out, driving the pressing plate 63 to move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com