Steel structure fabricated residual prefabricated concrete-filled steel tubular column and manufacturing method thereof

A technology of concrete-filled steel tubular columns and factory prefabrication, which is applied to columns, piers, pillars, etc., can solve the problems of many construction procedures, poor grouting, and large impact, and achieve the goal of improving construction progress, reducing project costs, and reducing occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

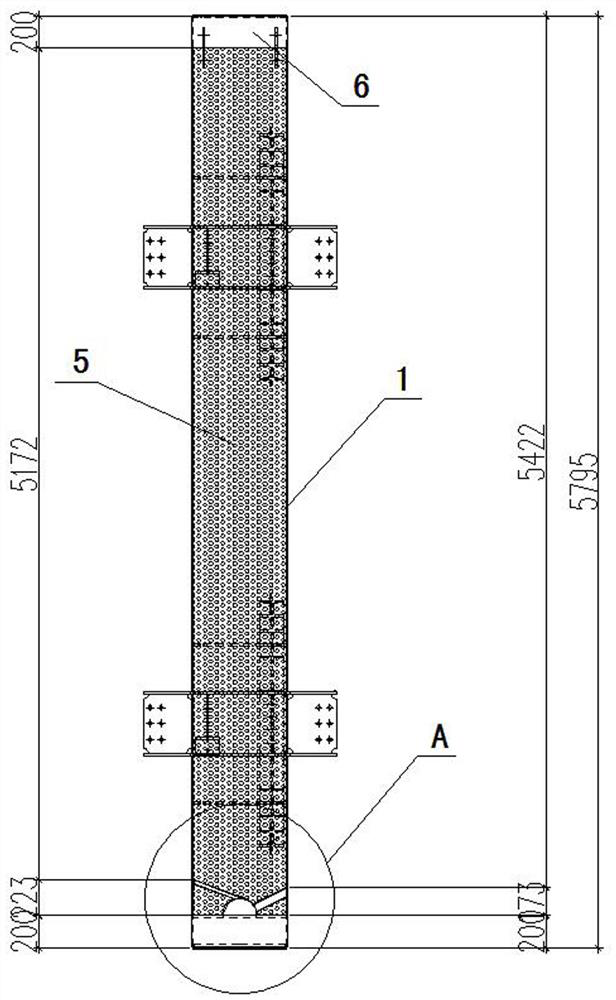

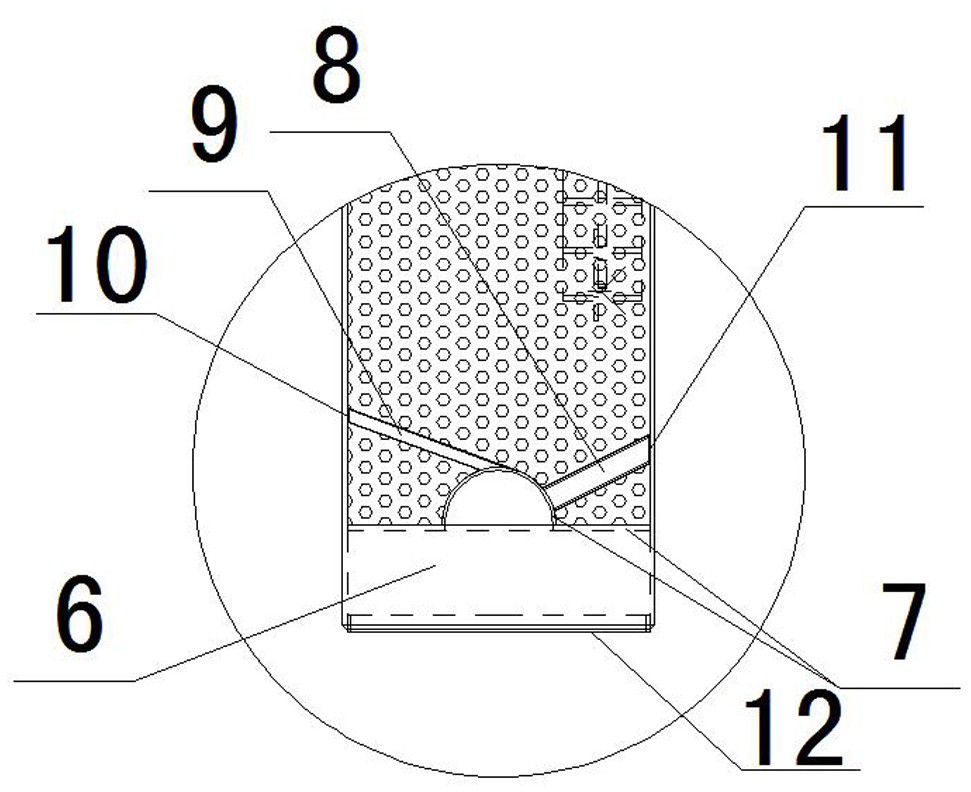

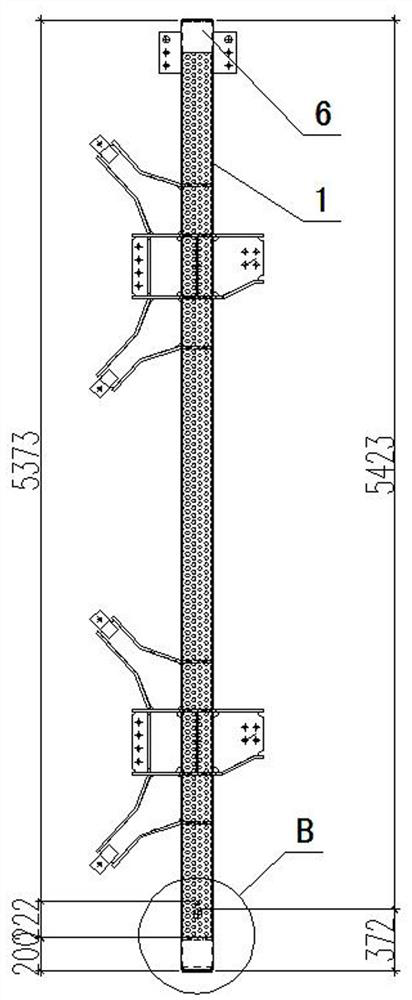

[0034] see Figure 1 to Figure 16 , a prefabricated steel pipe concrete column in a steel structure assembly house factory, including a steel pipe column 1, a grouting hole 3 and a vibration hole 4 are opened on the top plate 2 of the steel pipe column 1, and a concrete layer 5 is poured inside the steel pipe column 1, and the upper and lower butt joints There are docking cavities 6 at both ends, and special-shaped sealing plates 7 for sealing the concrete layer 5 are arranged in the lower docking cavities 6. The special-shaped sealing plates 7 are respectively provided with prefabricated observation panels connected with the lower docking cavities 6. The pipe 8 and the prefabricated grouting pipe 9, the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com