Compound, display panel and display device

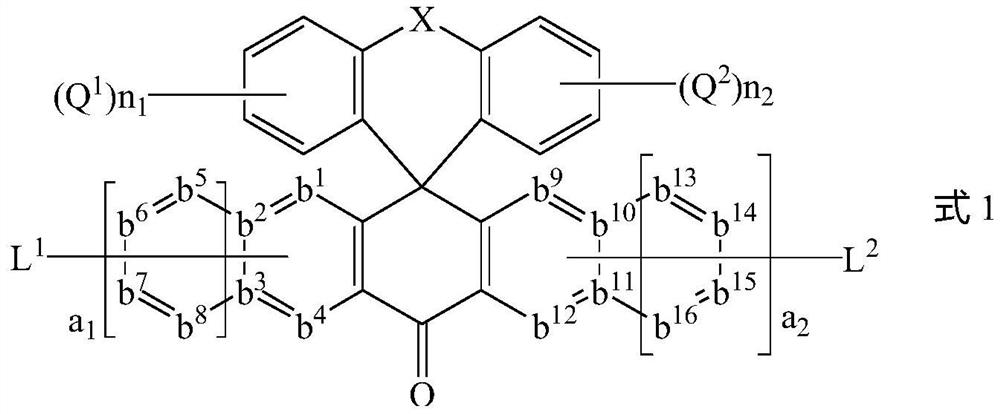

A display panel and compound technology, which is applied in the fields of compounds, display panels and display devices, can solve the problems of affecting OLED luminous quantum efficiency, reducing component efficiency and thermal stability, and reducing exciton formation efficiency, so as to achieve suppression of electron transport performance and Reduced exciton formation efficiency, enhanced electron injection and transport capabilities, and effects of high exciton utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Embodiment 1: the synthesis of compound H-25

[0131] (one)

[0132] Under nitrogen atmosphere, add re-2 (5mmol) to 100mL anhydrous THF, stir at -78°C for 10min, wait for the reaction solution to cool down, add 1.6M n-BuLi (5mmol) dropwise, and wait until the dropwise addition is complete, React at -78°C for 2h; dissolve re-1 (5mmol) into 50mL of anhydrous THF solution, and then drop it into the low-temperature reaction solution with a syringe. After the addition is complete, continue the reaction at low temperature for 1h, and then warm up to room temperature for reaction 6h. After the reaction is completed, add a small amount of water to quench, add water and dichloromethane to extract, collect the organic phase and dry it with anhydrous sodium sulfate, collect the filtrate by suction filtration, and spin off the solvent to obtain a crude product.

[0133] Add the above crude product into 80mL acetic acid under nitrogen, stir and heat, react at 120°C for 2h, then ...

Embodiment 2

[0139] Embodiment 2: the synthesis of compound H-50

[0140] (two)

[0141] The preparation method was similar to that of Example 1, except that re-3 in step (2) of Example 1 was replaced with an equimolar amount of re-4 to finally obtain the target compound H-50 (yield 78%).

[0142] LC-MS: m / z: Calculated: C58H36N4OS: 837.00, Found: 836.79.

[0143] Elemental analysis results of the compound: calculated value: C58H36N4OS (%): C 83.23, H 4.34, N 6.69; test value: C 83.24, H 4.35, N 6.70.

Embodiment 3

[0144] Embodiment 3: the synthesis of compound H-53

[0145] (two)

[0146] The preparation method was similar to that of Example 1, except that re-3 in step (2) of Example 1 was replaced with an equimolar amount of re-5 to finally obtain the target compound H-53 (yield 75%).

[0147] LC-MS: m / z: Calculated: C56H34N6OS: 838.97, Found: 838.61.

[0148] Compound elemental analysis results: calculated value: C56H34N6OS (%): C 80.17, H 4.08, N 10.02; test value: C 80.18, H 4.07, N 10.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com