Bamboo pipe slitter

A strip cutting machine and bamboo tube technology, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of machine contact injury, hand soreness, injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

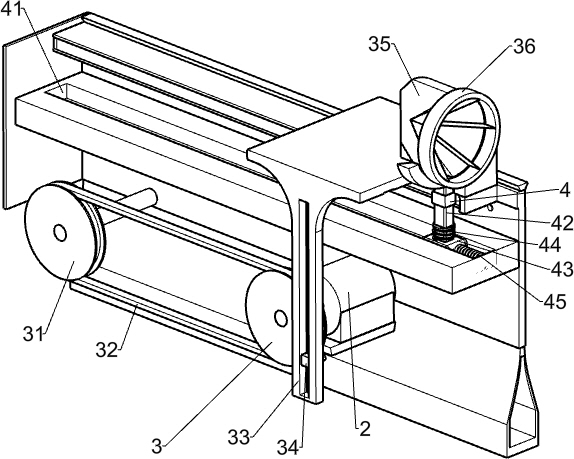

[0023] see figure 1 with figure 2 , a bamboo tube cutting machine, comprising a frame 1, a motor 2, a cutting assembly 3 and a support assembly 4, a cutting assembly 3 is provided between the top and the front of the frame 1, and the upper inside of the frame 1 is provided with Support assembly 4, support assembly 4 cooperates with sectioning assembly 3, motor 2 is installed on the right side of the lower part of the rear side of frame 1 by bolt connection, and the output shaft of motor 2 is connected with sectioning assembly 3 through coupling.

[0024] Cutting assembly 3 comprises belt pulley 31, transmission belt 32, slide frame 33, first slide block 34, concave push block 35 and conical combined knife 36, and the sliding type is provided with slide frame between frame 1 top front and rear sides 33. A concave push block 35 is fixedly connected to the middle part on the right side of the top of the sliding frame 33, and the concave push block 35 cooperates with the support...

Embodiment 2

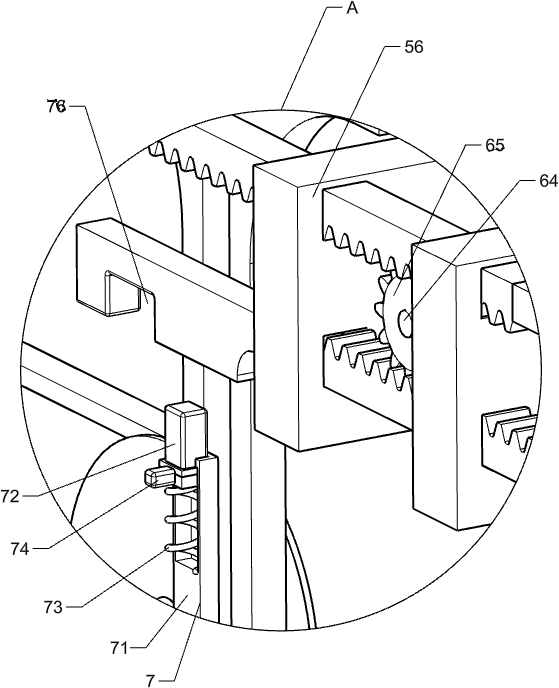

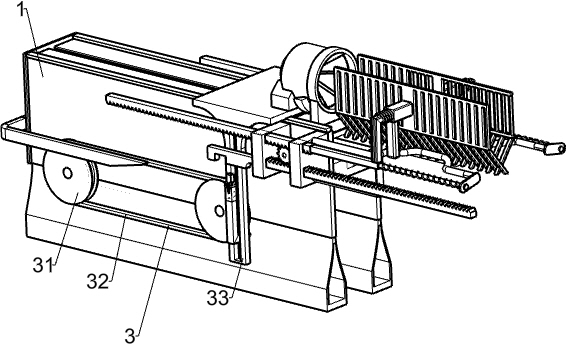

[0030] see image 3 with Figure 4 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a clamping assembly 5 is also included, and the clamping assembly 5 includes a splint 51, an L-shaped guide sleeve 52, a special-shaped connecting rod 53, and a limit rod 54 , the third spring 55, the mounting plate 56 and the transmission assembly 6, two mounting plates 56 are fixedly connected to the upper right side of the front and rear sides of the frame 1, and the transmission assembly 6 is arranged between the mounting plates 56 on the left and right sides, and the right side The middle part of the right side of the mounting plate 56 is fixedly connected with the limit rod 54, and the outside of the right part of the limit rod 54 is slidably matched with the transmission assembly 6. There is an L-shaped guide sleeve 52, and the inner end of the L-shaped guide sleeve 52 is fixedly connected with a splint 51. The splints 51 on the front and re...

Embodiment 3

[0035] see image 3 with Figure 4 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, it also includes a locking assembly 7, and the locking assembly 7 includes an L-shaped connecting rod 71, a third slider 72, a fifth Spring 73, connecting block 74 and limit block 75, frame 1 outer left side lower part is fixedly connected with limit block 75, the first slide block 34 front side is fixedly connected with L-shaped connecting rod 71, L-shaped connecting rod 71 outer front The upper side sliding type is provided with a third slider 72, and the lower part of the front side of the third slider 72 is fixedly connected with a connecting block 74. A fifth spring 73 is connected inside, and a groove 76 is formed on the left side of the bottom of the first rack 61 , and the groove 76 cooperates with the third sliding block 72 .

[0036] When the bamboo strips fell between the front and rear side clamping plates 51, the bamboo t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com