A hardware component cleaning device

A cleaning device and component technology, applied in cleaning methods and tools, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as leaving gaps in hardware structures, single ultrasonic treatment for cleaning structural frame grooves, and interference with cleaning quality, etc. , to achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

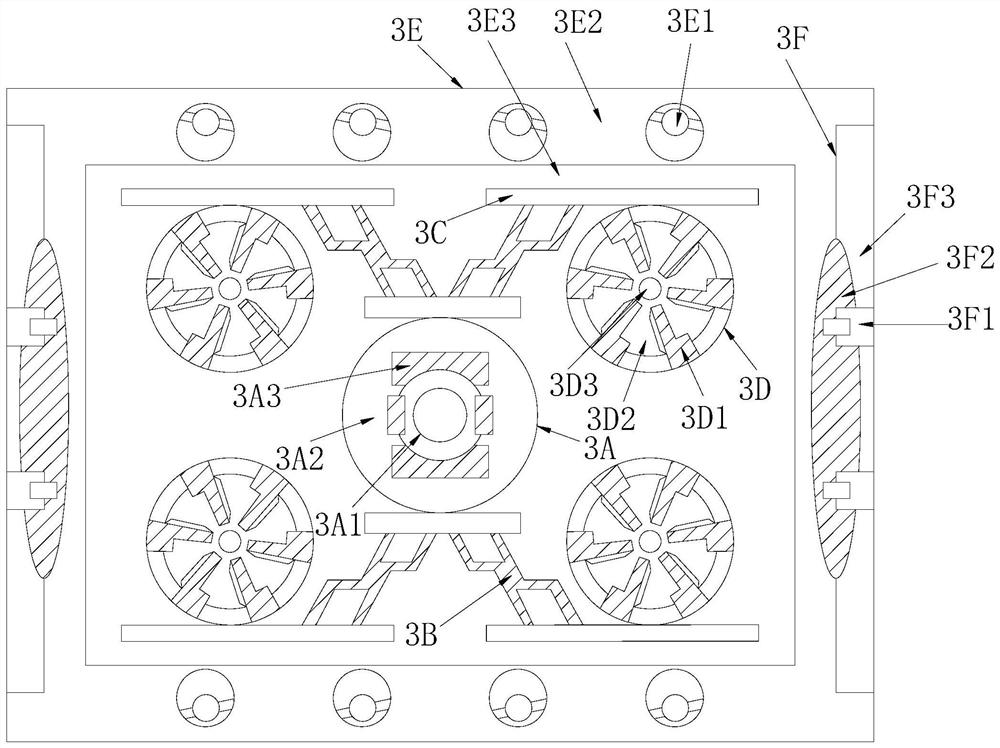

[0033] see Figure 1-Figure 6, the invention provides a cleaning device for hardware components, the structure of which includes: an aluminum shell square groove 1, a top cover plate 2, an inner groove of a vortex vibrating screen 3, an electric control panel 4, a facade baffle 5, a switch valve handle 6, a row The flow tube 7, the inner tank 3 of the vortex vibrating screen is installed in the square tank 1 of the aluminum shell, the electric control panel 4 is installed in the upper right corner of the square tank 1 of the aluminum shell, and the top cover plate 2 is nested in the vortex vibrating screen. On the top of the screen inner tank 3, the facade baffle plate 5 is closely attached to the square tank 1 of the aluminum shell and is on the same vertical plane, and the drain pipe 7 is inserted in the lower left corner of the square tank 1 of the aluminum shell And communicate with each other, the switch valve handle 6 is mechanically connected with the inner groove 3 of ...

Embodiment 2

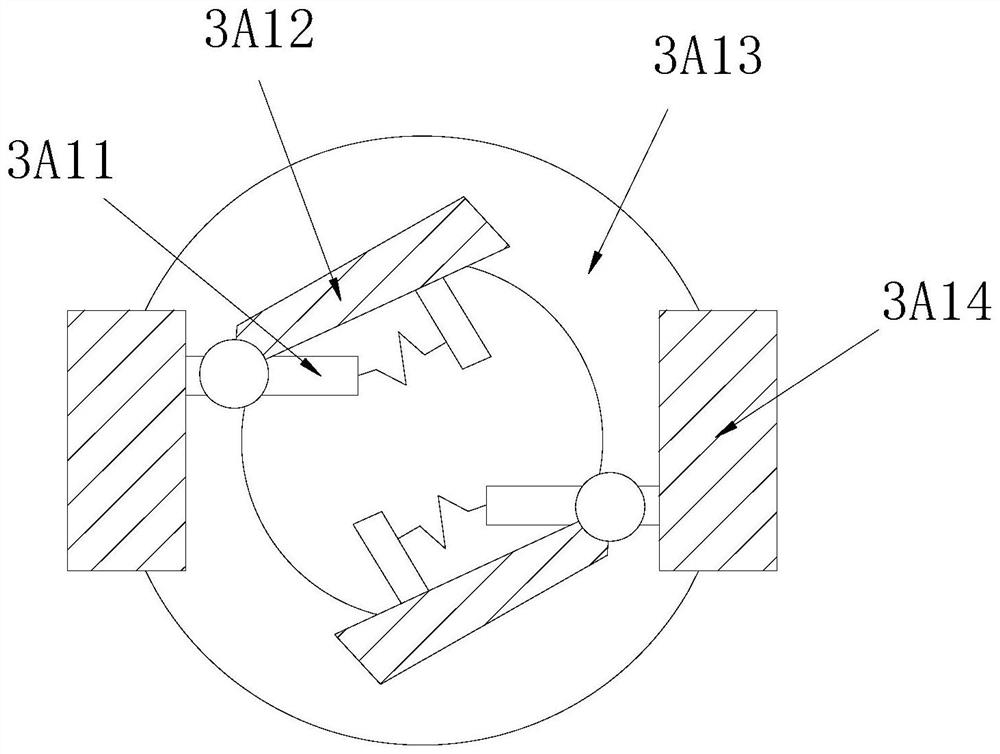

[0040] see Figure 1-Figure 6 , the present invention provides a hardware component cleaning device, other aspects are the same as in Embodiment 1, the difference is:

[0041] see figure 2 , the ultrasonic cushion 3F is composed of a sound wave generator 3F1, a flat ellipsoid 3F2, and a foam sound insulation board 3F3, and the flat ellipsoid 3F2 is nested on the left side of the foam sound insulation 3F3 and is on the same vertical plane Above, the sound wave generator 3F1 is embedded in the flat ellipsoid 3F2, and the sound wave generator 3F1 is inserted into the flat ellipsoid 3F2 to form the horizontal output of longitudinal air pressure to ensure the quality of ultrasonic waves and the frequency conversion of electronic control. operate.

[0042] see Figure 6 , the acoustic wave generator 3F1 is composed of a converging tube groove 3F11, a casing block 3F12, a cyclone inner chamber 3F13, and a photoelectric resonance tube 3F14, and the converging tube groove 3F11 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com