High-temperature storage method of lithium manganate battery

A lithium manganate battery and lithium manganate technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of poor cycle performance of batteries, poor storage performance of lithium manganate batteries, etc., and achieve improved The effect of chemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

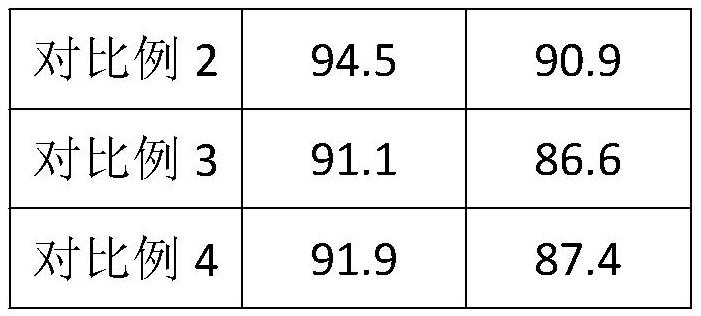

Examples

Embodiment 1

[0029] 1) Heat the assembled lithium manganate battery to 40°C;

[0030] 2) injecting the first electrolytic solution at normal temperature, the solvent of the first electrolytic solution is ethylene carbonate, which contains 5% by mass of bromobutyrolactone;

[0031] 3) Adjust the temperature of the battery to 10°C, charge the battery with a constant current of 1C to a first predetermined voltage, and the first predetermined voltage is 3.64V;

[0032] 4) Adjust the temperature of the battery to 40°C, and charge the battery at a constant voltage at the first predetermined voltage until the current is lower than the cut-off current by 0.01C;

[0033] 5) Inject the second electrolyte solution at normal temperature, the volume ratio of the first electrolyte solution and the second electrolyte solution is 65:35. The solvent of the second electrolyte solution is dimethyl carbonate, which contains 6% by mass of 1, 4-butane sultone;

[0034] 6) Adjust the temperature of the battery...

Embodiment 2

[0039] 1) Heat the assembled lithium manganate battery to 50°C;

[0040] 2) injecting the first electrolytic solution at normal temperature, the solvent of the first electrolytic solution is ethylene carbonate, which contains 8% by mass of bromobutyrolactone;

[0041] 3) Adjust the battery temperature to 10°C, and charge the battery with a constant current of 1C to the first predetermined voltage, and the first predetermined voltage is 3.68V;

[0042] 4) Adjust the temperature of the battery to 50°C, and charge the battery at a constant voltage at the first predetermined voltage until the current is lower than the cut-off current by 0.01C;

[0043] 5) Inject the second electrolyte solution at normal temperature, the volume ratio of the first electrolyte solution and the second electrolyte solution is 75:25. The solvent of the second electrolyte solution is dimethyl carbonate, which contains 10% by mass of 1, 4-butane sultone;

[0044] 6) Adjust the battery temperature to 10°...

Embodiment 3

[0049] 1) Heat the assembled lithium manganate battery to 45°C;

[0050] 2) Inject the first electrolyte solution at normal temperature, the solvent of the first electrolyte solution is ethylene carbonate, which contains 7% by mass of bromobutyrolactone;

[0051] 3) Adjust the battery temperature to 5°C, and charge the battery with a constant current of 1C to the first predetermined voltage, and the first predetermined voltage is 3.66V;

[0052] 4) Adjust the battery temperature to 45°C, and charge the battery at a constant voltage at the first predetermined voltage until the current is lower than the cut-off current by 0.01C;

[0053] 5) inject the second electrolytic solution at normal temperature, the volume ratio of the first electrolytic solution and the second electrolytic solution is 7:3, the solvent of the second electrolytic solution is dimethyl carbonate, which contains 9% by mass of 1, 4-butane sultone;

[0054] 6) Adjust the temperature of the battery to 5°C, cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com