A dry gas sealed self-cooling structure and method

A dry gas sealing, self-cooling technology, applied in the direction of machine/engine, leakage prevention, mechanical equipment, etc., can solve the limited temperature tolerance of flexible plastic sealing ring, can not meet the application requirements of supercritical carbon dioxide turbine high temperature conditions, etc. problem, to achieve the effect of solving the dynamic sealing problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

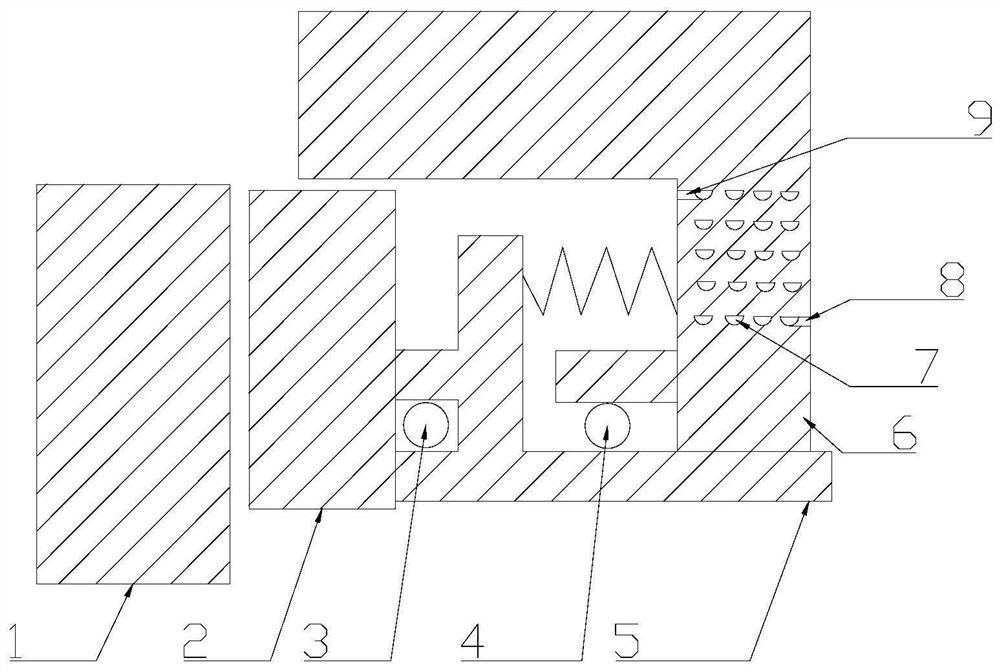

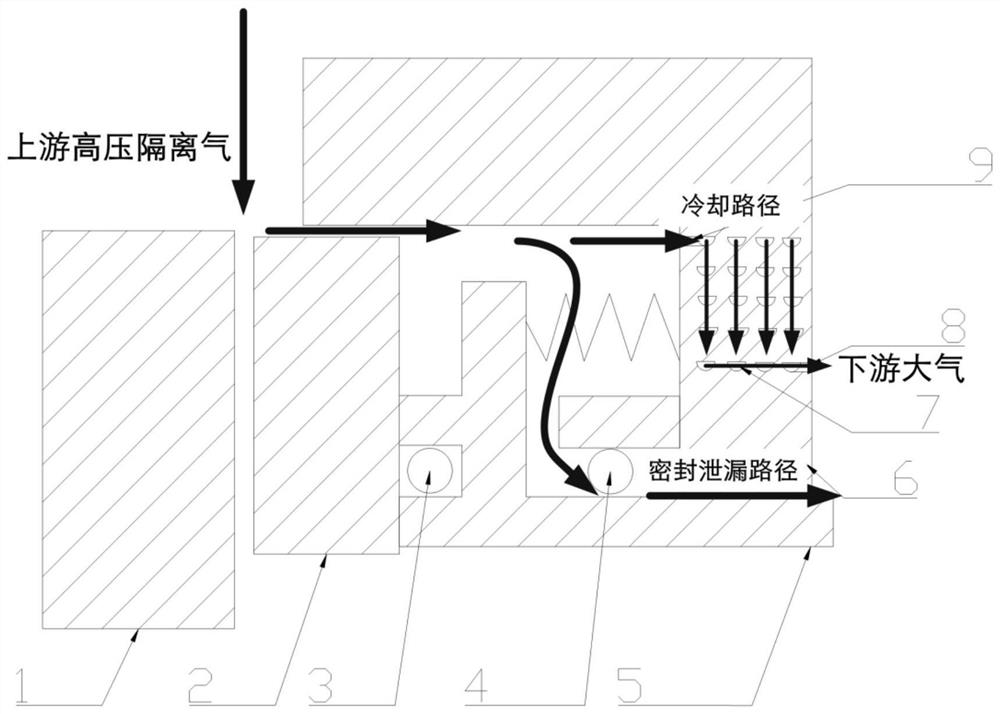

[0037] Such as Figure 1 ~ Figure 3 As shown, the dry gas seal is moving ring 1, static ring 2, push ring 5, and spring seat 6 from left to right. The gas sealing function between the push rings 5, the second sealing gasket 4 is placed between the push ring 5 and the spring seat 6, and plays the gas sealing function between the push ring 5 and the spring seat 6. The push ring 5 is connected with the fixed spring seat 6 through a spring, so that the push ring 5 can move with the static ring 2 and play a role of dynamic sealing.

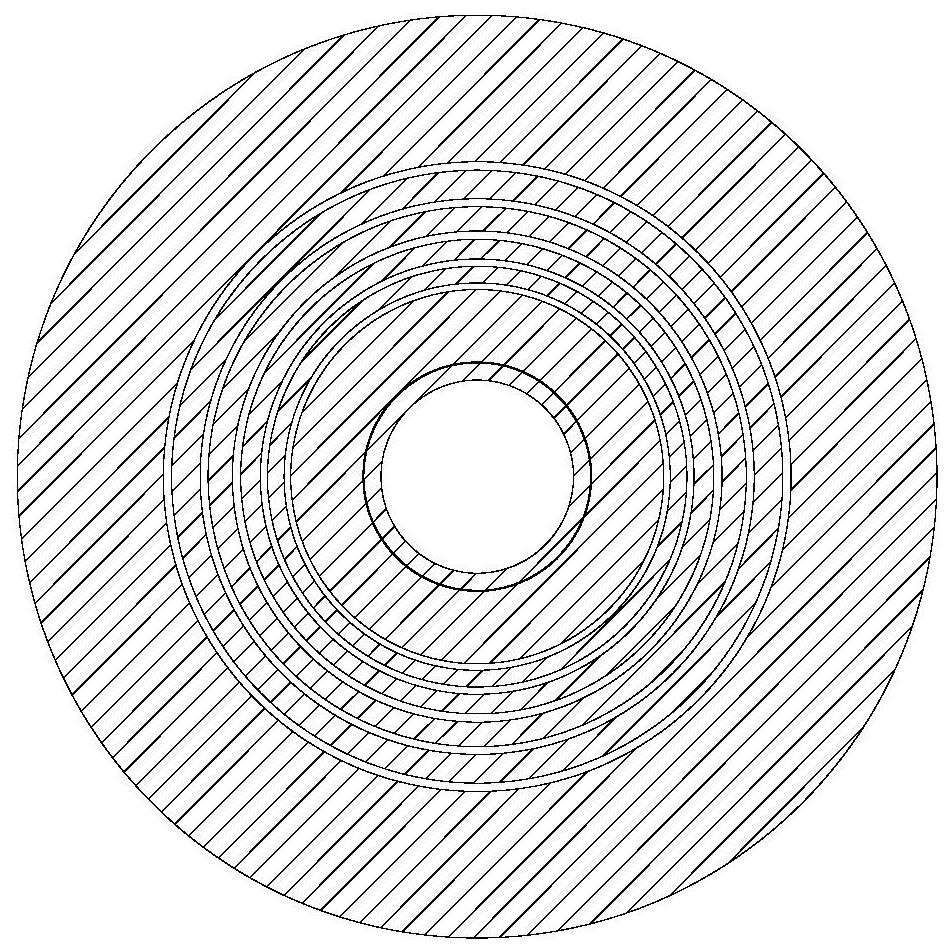

[0038] The spring seat 6 is provided with 5 rows of internal cooling micro-ring holes 7 from the inside to the outside in the radial direction, and the hole diameter is 0.2mm. Each row of internal cooling micro-ring holes 7 is provided with 5 rows of internal cooling micro-ring holes 7 according to the width of the spring seat 6. Constitute the internal cooling micro-ring hole matrix. The internal cooling micro-annular holes 7 are connected to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com