Fire-proof physical connection type composite disassembling-free thermal insulation formwork and production and manufacture technology thereof

A technology of thermal insulation formwork and physical connection, applied in thermal insulation, fire protection, building structure and other directions, can solve the problems of difficulty in forming a safe and reliable connection, the quality of the dismantling-free thermal insulation formwork becomes larger, and the external fire protection capability is not enough. Effects of fire risk and hazards, increased thickness, and reduced breakage rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

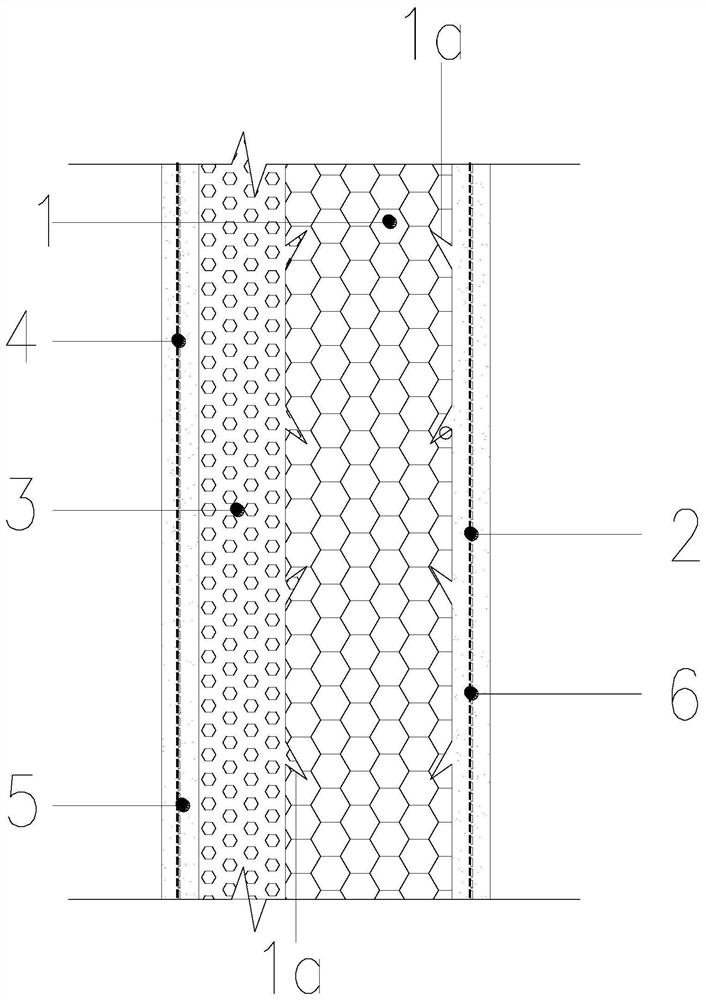

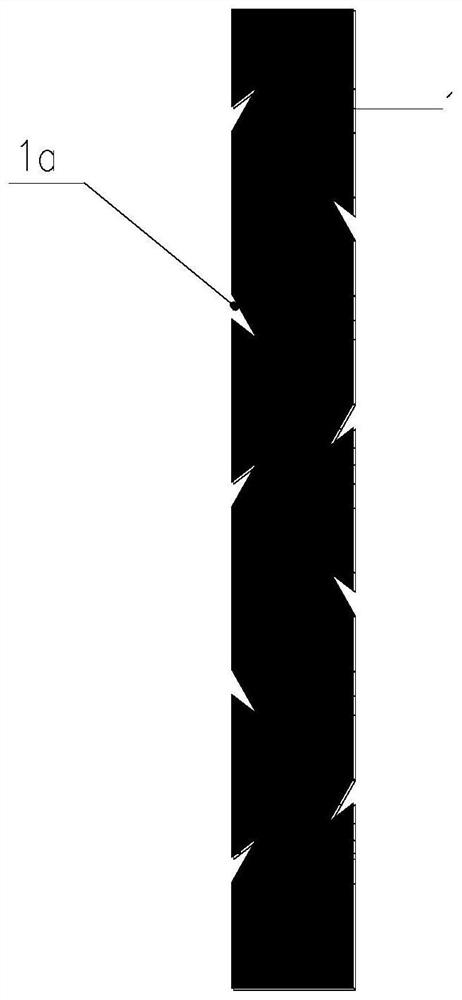

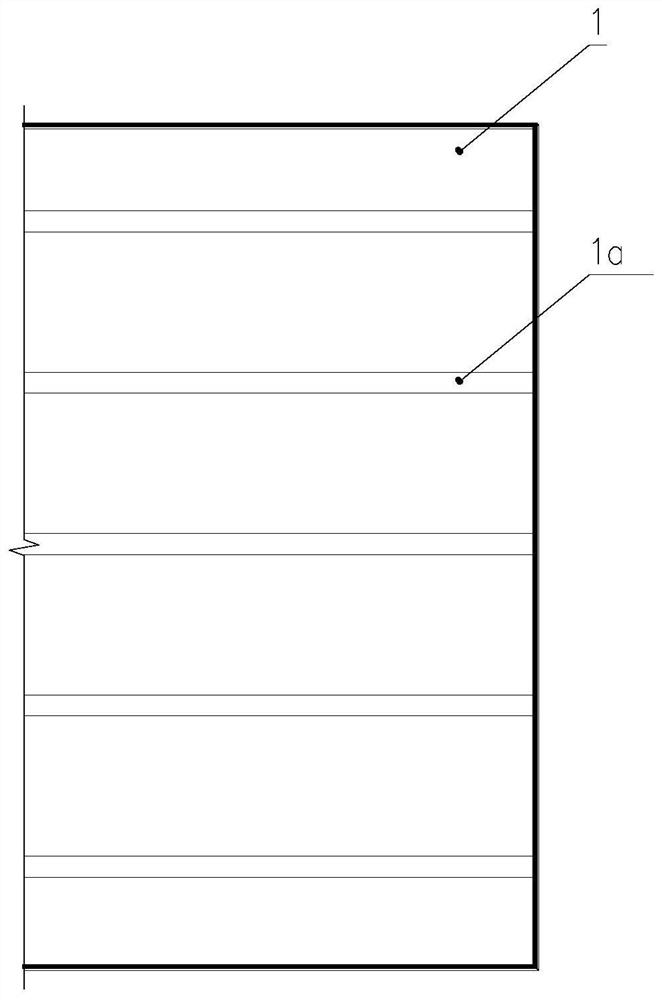

[0028] Referring to the accompanying drawings, a fire-proof physically connected composite non-dismantling thermal insulation formwork includes a thermal insulation core material 1 arranged in the middle. The groove 1a is an oblique triangular groove, and the adjacent oblique triangular grooves on the same side are arranged symmetrically up and down. The length of the projection of the groove 1a in the thickness direction of the insulation core material 1 is greater than the projection length of the notch. The inner surface of the insulation core material 1 A stress protection layer 6 is set, and the inner side of the stress protection layer 6 is placed in the slot 1a; two layers are arranged on the outer side of the thermal insulation core material 1 from the inside to the outside, and the inner layer of the two layers is the fireproof structure layer 3 and the outer layer. The layer is the protective layer 5, the fireproof insulation layer composed of the fireproof structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com