Transparent ion-conductive cellulose hydrogel and its preparation method and application

A cellulose hydrogel, ionic conduction technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, fluid pressure measurement using piezoelectric devices, etc. The effect of low requirements, wide and cheap raw material sources, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

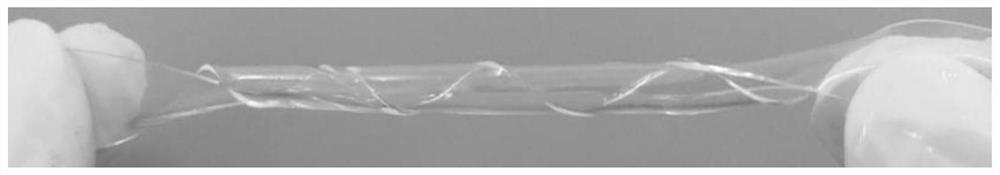

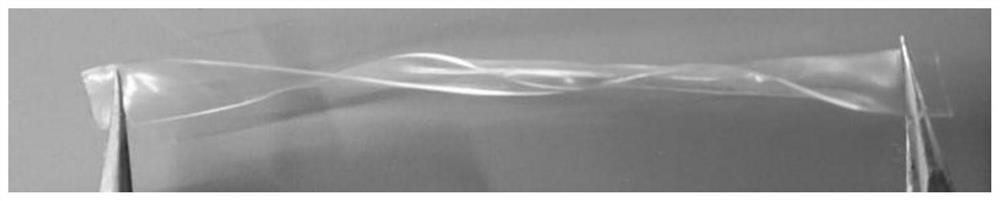

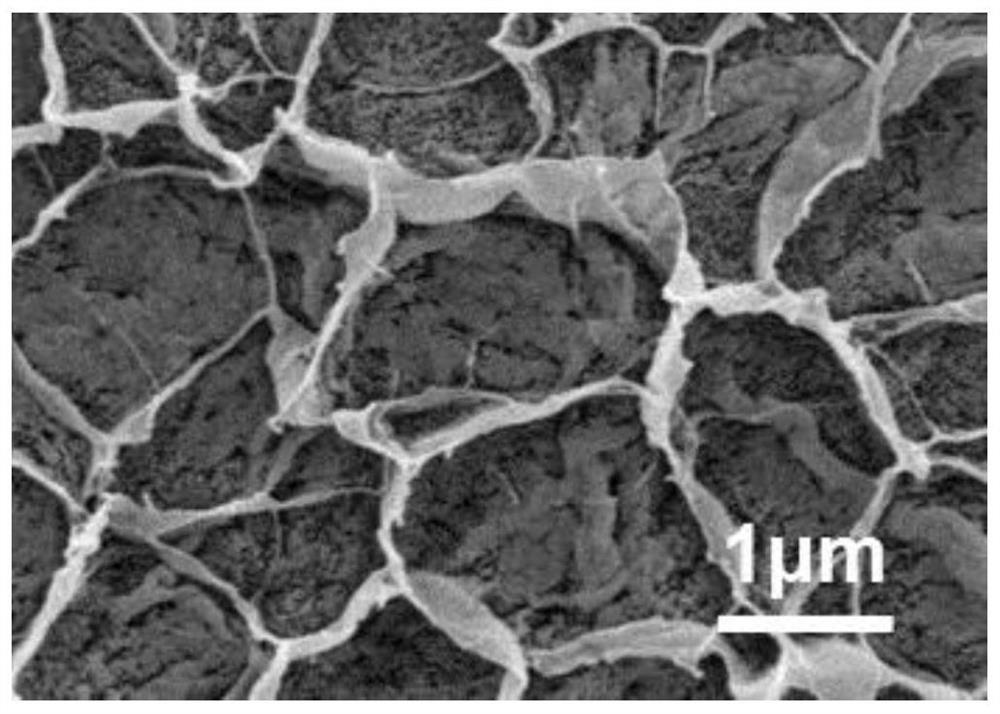

[0041] Set the molecular weight to 1.08×10 5 The cotton linter cellulose is dispersed in 1.88mol / L benzyltrimethylammonium hydroxide aqueous solution, frozen at -24°C for 12 hours until the dispersion is completely frozen, then thawed at room temperature, centrifuged and defoamed to obtain a clear and transparent of cellulose solution. Add 0.4 mL of epichlorohydrin dropwise to 15 g of cellulose solution, stir in an ice-water bath to disperse the epichlorohydrin evenly in the cellulose solution, and mix the obtained epichlorohydrin / cellulose The mixed solution was degassed by centrifugation at 0 °C, and the obtained clear solution was spread on a glass plate by the continuous flow method. First put it in a windless environment at 20°C, put it in a coagulation bath of 1mol / L NaCl aqueous solution after 2 hours, and then put the coagulation bath in a refrigerator at 0°C for 24 hours, and the obtained cellulose ionized water coagulates The tensile strength of the adhesive is 2.5...

Embodiment 2

[0043] Set the molecular weight to 1.08×10 5The cotton linter cellulose is dispersed in 1.88mol / L benzyltrimethylammonium hydroxide aqueous solution, frozen at -24°C for 12 hours until the dispersion is completely frozen, then thawed at room temperature, centrifuged and defoamed to obtain a clear and transparent of cellulose solution. Add 0.4 mL of epichlorohydrin dropwise to 15 g of cellulose solution, stir in an ice-water bath to disperse the epichlorohydrin evenly in the cellulose solution, and mix the obtained epichlorohydrin / cellulose The mixed solution was degassed by centrifugation at 0 °C, and the obtained clear solution was spread on a glass plate by the continuous flow method. First put it in a windless environment at 20°C, put it in a coagulation bath of 3mol / L NaCl aqueous solution after 2 hours, and then put the coagulation bath in a refrigerator at 0°C for 24 hours, and the obtained cellulose ionized water coagulates The tensile strength of the glue is 5.2MPa, ...

Embodiment 3

[0045] Set the molecular weight to 1.08×10 5 The cotton linter cellulose is dispersed in 1.88mol / L benzyltrimethylammonium hydroxide aqueous solution, frozen at -24°C for 12 hours until the dispersion is completely frozen, then thawed at room temperature, centrifuged and defoamed to obtain a clear and transparent of cellulose solution. Add 0.5 mL of glycidyl ether dropwise to 15 g of cellulose solution, stir in an ice-water bath to disperse the glycidyl ether evenly in the cellulose solution, and after 20 min, place the obtained glycidyl ether / cellulose mixed solution in Centrifuge and defoam at 0°C, and the resulting clear solution is spread on a glass plate by the continuous flow method. First place it in a windless environment at 20°C, and then put it into a coagulation bath of 2.5mol / L NaCl / water / ethylene glycol solution after 2 hours, wherein the mass ratio of water to ethylene glycol is 60 Ratio of 40, then put the coagulation bath into the refrigerator at 0°C and let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| Freeze resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com