Method for preparing hydrotalcite-assisted vanadium-phosphorus-oxygen catalyst

A technology of vanadium phosphorus oxide and hydrotalcite, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of insignificant effect, achieve selectivity and conversion rate improvement, simple synthesis, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

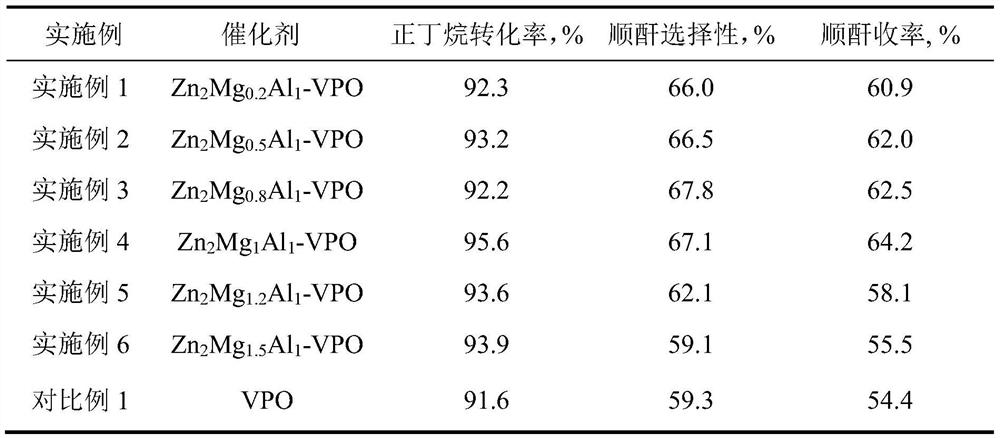

Examples

preparation example Construction

[0017] An embodiment of the present invention provides a method for preparing a hydrotalcite-assisted vanadium-phosphorus-oxygen catalyst, which includes the following steps:

[0018] Preparation of vanadium phosphorus oxide precursor: vanadium source, benzyl alcohol and C 3 ~C 8 The monohydric alcohol is mixed to obtain a mixture, then a phosphorus source is added, the temperature is raised to 100°C to 200°C, the reaction is continued, the product is filtered and dried, and the vanadium phosphorus oxide precursor is obtained;

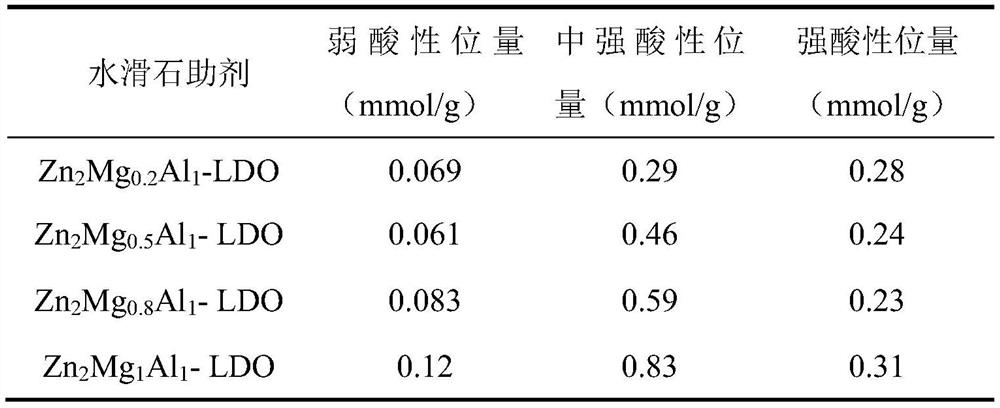

[0019] Preparation of hydrotalcite additive: Dissolve water-soluble inorganic zinc source, inorganic magnesium source, and inorganic aluminum source in water, add alkali source, heat to 65-200°C for reaction, age for 6-12 hours after cooling down, filter, wash, dry, and Roasting at 350-550°C to obtain the hydrotalcite additive;

[0020] The hydrotalcite additive is mixed with the vanadium phosphorus oxygen precursor according to a mass ratio of 1-10:...

Embodiment 1

[0031] Preparation of Vanadium Phosphate Precursor

[0032] Weigh 13.5g V 2 o 5 Mix with benzyl alcohol and isobutanol, heat and reflux at 135°C for 3h under mechanical stirring, then cool down to 80°C, add 9.4mL of phosphoric acid with a mass fraction of 85wt%, raise the temperature to 135°C, and heat to reflux for 16h under continuous stirring Afterwards, the obtained product is filtered and dried to obtain a solid and dried to obtain a vanadium phosphorus oxide precursor.

[0033] Preparation of hydrotalcite additives: Zn 2 Mg 0.2 Al 1 -LDO

[0034] Molebi Zn 2+ :Mg 2+ :Al 3+ Weigh Zn(NO 3 ) 2 ·6H 2 The mass of O is 11.91g, Mg(NO 3 ) 2 ·6H 2 The mass of O is 1.03g, Al(NO3 ) 2 9H 2 The quality of O is 7.5g, the metal salt that weighs is put into 500mL there-necked flask, then adds 12.68g urea (n 尿素 =3.3×n(Zn 2+ +Mg 2+ +Al 3+ )) Then add 200mL of water, react at 120°C for 6h under magnetic stirring, then age for 12h, filter with suction, wash, and dry to o...

Embodiment 2

[0038] Preparation of Vanadium Phosphate Precursor

[0039] Weigh 13.5g V 2 o 5 Mix with benzyl alcohol and isobutanol, heat and reflux at 135°C for 3h under mechanical stirring, then cool down to 80°C, add 9.4mL of phosphoric acid with a mass fraction of 85%wt, raise the temperature to 135°C, and heat to reflux for 16h under continuous stirring Afterwards, the obtained product is filtered and dried to obtain a solid and dried to obtain a vanadium phosphorus oxide precursor.

[0040] Preparation of hydrotalcite additives: Zn 2 Mg 0.5 al 1 -LDO

[0041] Molebi Zn 2+ :Mg 2+ :Al 3+ Weigh Zn(NO 3 ) 2 ·6H 2 The mass of O is 11.91g, Mg(NO 3 ) 2 ·6H 2 The mass of O is 2.56g, Al(NO 3 ) 2 9H 2 The quality of O is 7.5g, the metal salt that weighs is put into 500mL there-necked flask, then adds 13.87g urea (n 尿素 =3.3×n(Zn 2+ +Mg 2+ +Al 3+ )), reacted at 120°C for 6h under magnetic stirring, then aged for 12h, suction filtered, washed, and dried to obtain Zn 2 Mg 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com