Hydrogel ultrafiltration membrane as well as preparation method and application thereof

A technology of ultrafiltration membranes and hydrogels, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of low flux of ultrafiltration membranes and poor oil-water separation effect, and achieve large water fluxes , Excellent oil-water separation effect, high oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

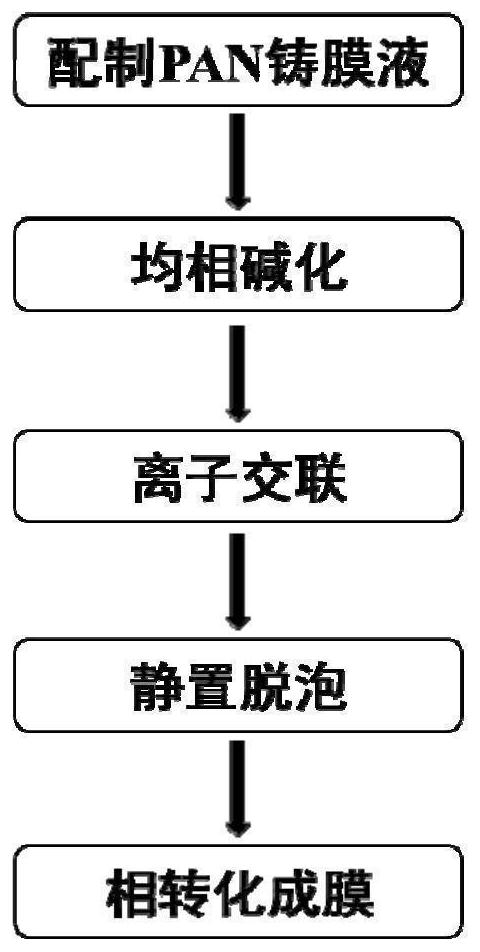

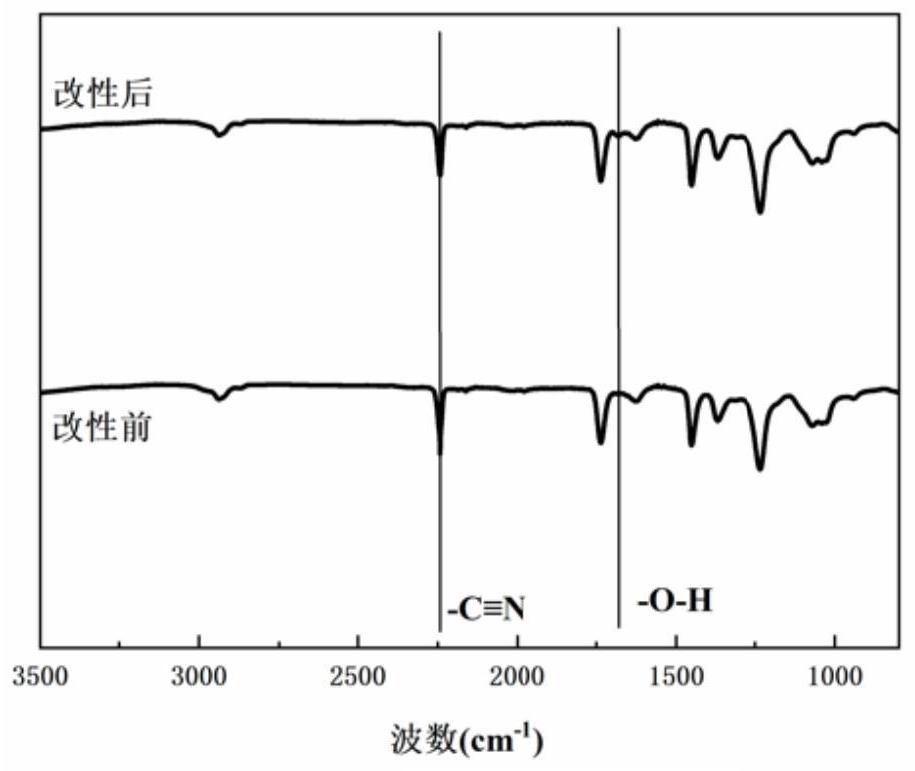

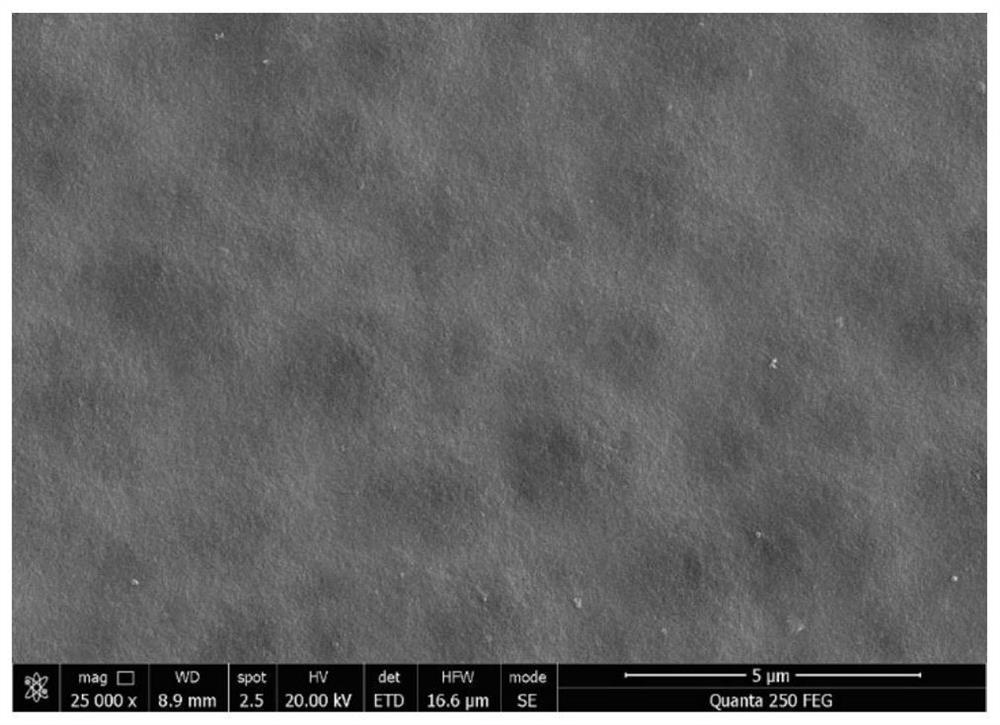

[0052] figure 1 Prepare flow chart for hydrogel ultrafiltration membrane of the present invention, as figure 1 Shown, the preparation method of the hydrogel ultrafiltration membrane of the present embodiment is as follows:

[0053] 1) Preparation of polyacrylonitrile casting solution: polyacrylonitrile (PAN) was dissolved in DMF to prepare a PAN casting solution with a concentration of 10 mg / mL and a volume of 10 mL;

[0054] 2) Under the condition of stirring at 90°C, add 0.4 mL of NaOH aqueous solution (NaOH / H 2 (2, 0.1mol / L) and then continue to react for 4h;

[0055] 3) then dripping 0.6mL concentration is the cupric chloride solution of 0.2mol / L, and described cupric chloride solution is that cupric chloride is dissolved in DMF and prepares (CuCl 2 / DMF, 0.2mol / L), continue to react for 4h and then stand at 90°C for 2h for defoaming.

[0056] 4) Pour the casting solution obtained after step 3) on a dry and clean glass plate, scrape it flat with a casting knife, then i...

Embodiment 2

[0061] The preparation method of the hydrogel ultrafiltration membrane of the present embodiment is as follows:

[0062] 1) Prepare PAN casting solution: dissolve PAN in DMF to prepare a PAN casting solution with a concentration of 18mg / mL and a volume of 10mL;

[0063] 2) Under the condition of stirring at 80°C, add 0.4 mL of NaOH aqueous solution (NaOH / H 2 (2, 0.6mol / L) and then continue to react for 5h;

[0064] 3) then dripping 0.8mL concentration is the cupric chloride solution of 0.1mol / L, and described cupric chloride solution is to be prepared by dissolving cupric chloride in DMF (CuCl 2 / DMF, 0.1mol / L), continue to react for 3h and then stand at 80°C for 5h for defoaming.

[0065] 4) Pour the casting solution obtained after step 3) on a dry and clean glass plate, scrape it flat with a casting knife, then immediately soak the glass plate and the scraped film into deionized water for phase inversion, and finally put the film Store in deionized water.

Embodiment 3

[0067] The preparation method of the hydrogel ultrafiltration membrane of the present embodiment is as follows:

[0068] 1) Prepare PAN casting solution: dissolve PAN in DMF, prepare PAN casting solution with a concentration of 16mg / mL, and the volume is 10mL;

[0069] 2) Under the condition of stirring at 60°C, add 0.4 mL of NaOH aqueous solution (NaOH / H 2 (2, 0.25mol / L) and then continue to react for 3h;

[0070] 3) then dripping 0.8mL concentration is the ferric chloride solution of 0.6mol / L, and described cupric chloride solution is to be prepared by dissolving cupric chloride in DMF (FeCl 3 / DMF, 0.6mol / L), continue to react for 5h and then stand at 60°C for 3h for defoaming.

[0071] 4) Pour the casting solution obtained after step 3) on a dry and clean glass plate, scrape it flat with a casting knife, then immediately soak the glass plate and the scraped film into deionized water for phase inversion, and finally put the film Store in deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com