Method for preparing patterned silicon structure and silicon-based photovoltaic cell

A patterned, silicon-structured technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of increasing the manufacturing cost of photovoltaic cells, limited anti-reflection performance, low contrast, etc., to improve photoelectric conversion efficiency and avoid viewing angles. Problem, effect of improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

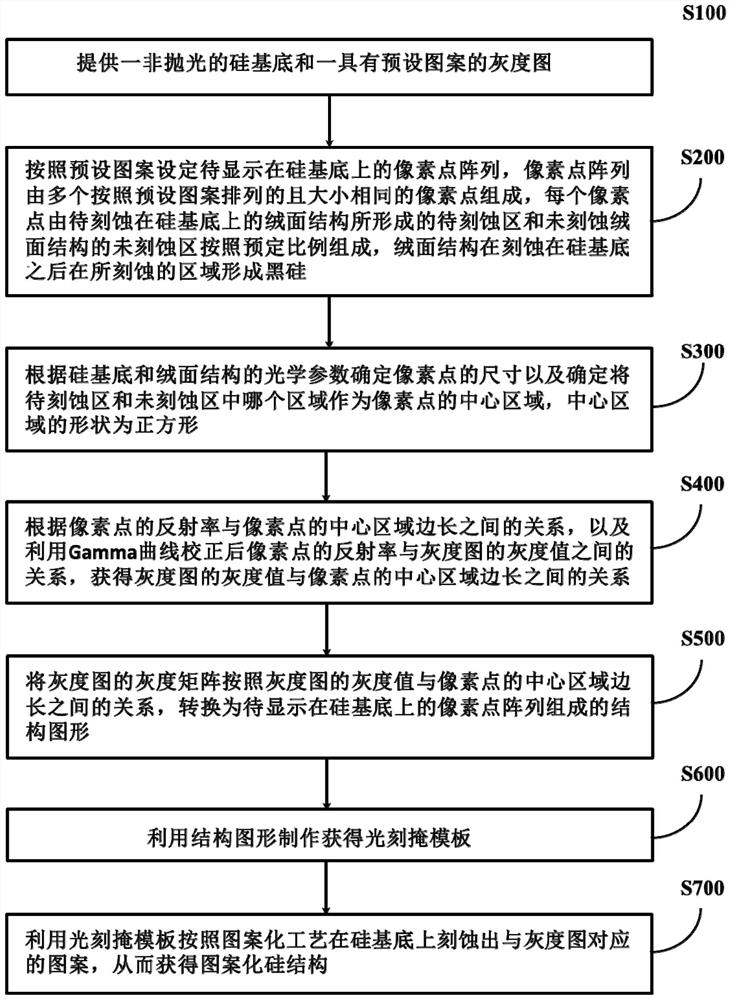

[0063] figure 1 A schematic flowchart of a method for fabricating a patterned silicon structure according to an embodiment of the present invention is shown. This preparation method is used to display a grayscale image on a non-polished silicon substrate, and the pattern displayed on the silicon substrate is composed of a plurality of pixels with different reflectivities, such as figure 1 Shown, this preparation method comprises:

[0064] Step S100, providing a non-polished silicon substrate and a grayscale image with a preset pattern;

[0065] Step S200, setting the pixel point array to be displayed on the silicon substrate according to the preset pattern, the pixel point array is composed of a plurality of pixels arranged according to the preset pattern and having the same size, and each pixel point is formed by the silicon substrate to be etched The region to be etched formed by the textured structure on the substrate and the unetched region of the textured structure not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com