Target material secondary utilization method

A technology of target material and splicing method, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of easy mixing of impurities and affecting the purity of metals, and achieve high recycling rate, cost saving, and two Guaranteed performance for the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

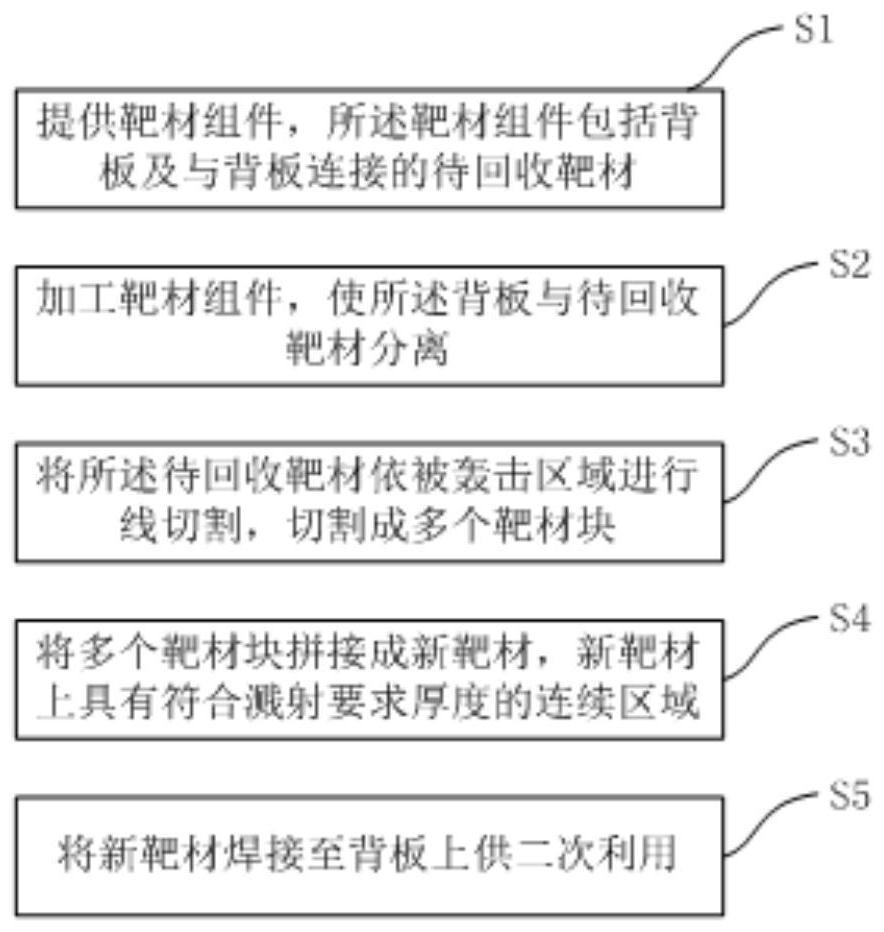

[0029] see Figure 1 to Figure 5 As shown, the present invention provides a target secondary utilization method, comprising the following steps:

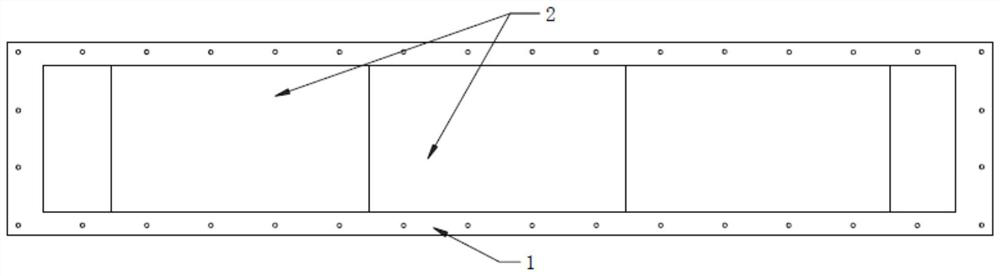

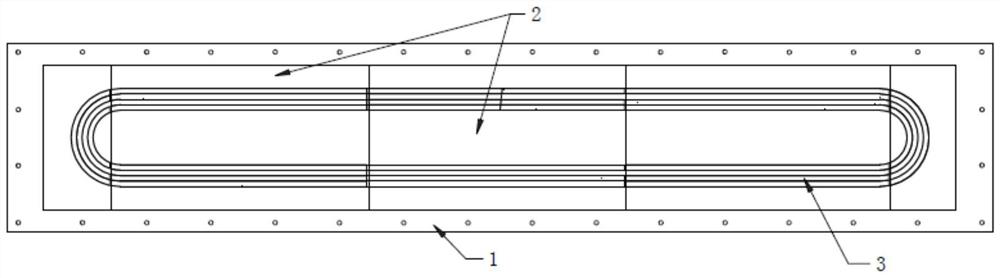

[0030] S1: Provide a target assembly, the target assembly includes a backplane 1 and a target to be recovered 2 connected to the backplane 1, wherein the target to be recovered 2 has a bombarded area 3, and the thickness of the bombarded area 3 is smaller than other areas ;

[0031] S2: Process the target assembly to separate the back plate 1 from the target 2 to be recovered;

[0032] S3: wire-cut the target material 2 to be recovered according to the bombarded area 3, and cut it into multiple target material blocks;

[0033] S4: Splicing a plurality of target blocks into a new target, wherein the new target has a continuous area with a thickness meeting the sputtering requirement;

[0034] S5: welding the new target to the back plate for secondary use.

[0035] Further, as image 3 As shown, the bombardment area of common t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com