Glass forming bead dripping stove and glass forming system

A technology for glass forming and forming molds, which is applied in glass manufacturing equipment, furnaces, boilers, etc., and can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

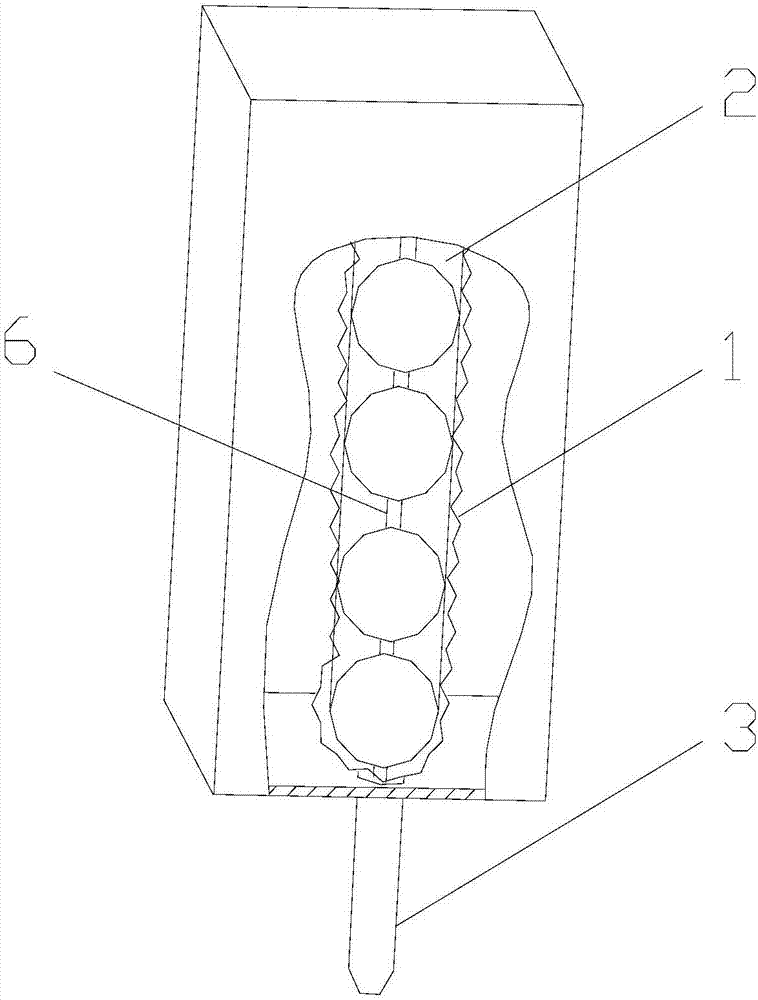

[0040] In the optional scheme of this embodiment, such as figure 1 As shown, a glass forming drip furnace provided in this embodiment includes a heating device 1, a crucible device 2 and a discharge nozzle device 3; the heating device 1 is used to heat the crucible device 2; the crucible device 2 is used to accommodate and Melting glass powder; the discharge nozzle device 3 is vertically connected to the bottom of the crucible device 2 and communicated with the inner cavity of the crucible device 2 .

[0041] Such as Figure 4 As shown, the molding process of the traditional sealing glass is granulation with solder and binder, pressing the blank 7 through a powder press, and then sintering it into a sintering furnace 8 to form it.

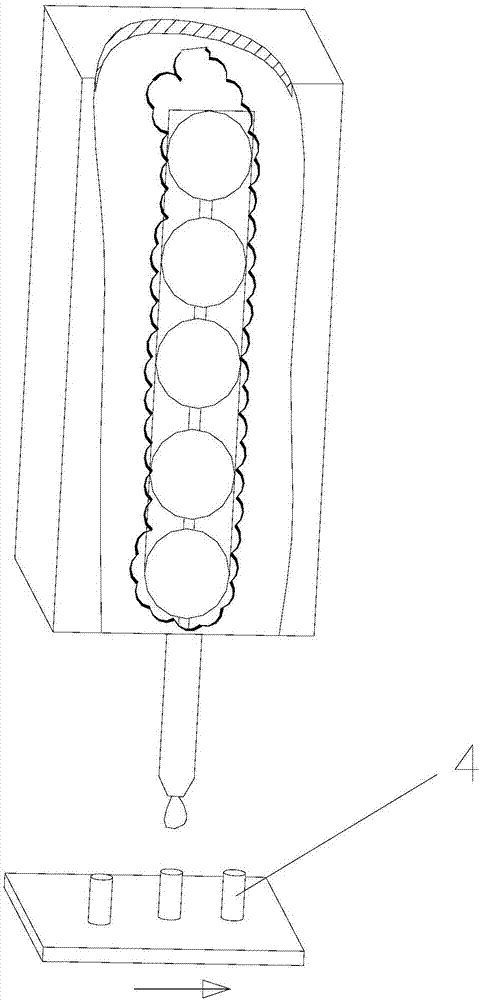

[0042] In this embodiment, the heating device 1 heats the crucible device 2 to 400-1000° C., adds the glass powder into the crucible device 2 and keeps it warm for 10-30 minutes. The glass powder in the crucible device 2 melts and flows into the ...

Embodiment 2

[0062] In the optional scheme of this embodiment, such as figure 1 As shown, a glass forming drip furnace provided in this embodiment includes a heating device 1, a crucible device 2 and a discharge nozzle device 3; the heating device 1 is used to heat the crucible device 2; the crucible device 2 is used to accommodate and Melting glass powder; the discharge nozzle device 3 is vertically connected to the bottom of the crucible device 2 and communicated with the inner cavity of the crucible device 2 .

[0063] In this embodiment, the heating device 1 heats the crucible device 2 to 400-1000° C., adds the glass powder into the crucible device 2 and keeps it warm for 10-30 minutes. The glass powder in the crucible device 2 melts and flows into the In the discharge nozzle device 3, the liquid glass drops from the bottom of the discharge nozzle device 3 in the form of droplets depending on its own weight and surface tension, and forms glass beads after cooling, or is collected and c...

Embodiment 3

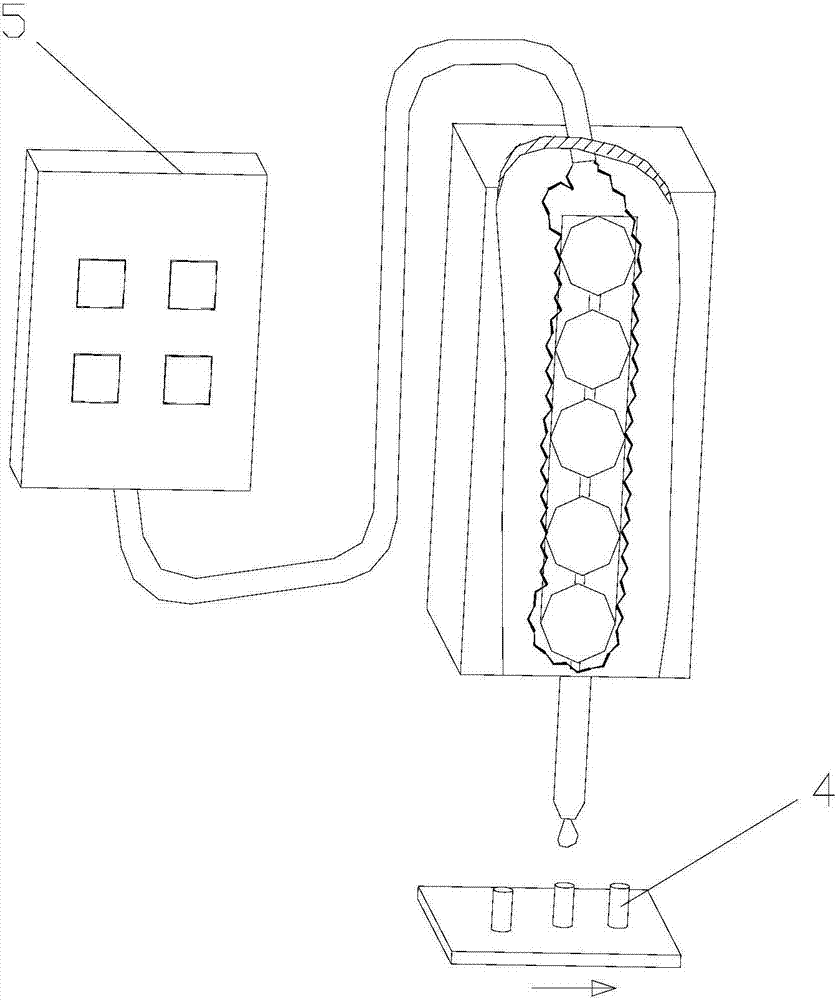

[0086] In an optional solution of this embodiment, a glass forming system provided in this embodiment includes the glass forming bead furnace as described in Embodiment 1 or Embodiment 2.

[0087] In this embodiment, a glass powder feeding device can be provided to feed glass powder into the bead-drop furnace for glass forming according to a certain weight and frequency. After the glass is formed, it will be cut or packaged by other devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com