Gangue paste cementing material and preparation method thereof, gangue paste filling material and preparation method thereof

A technology of cementing material and gangue, which is applied in the field of mine filling, can solve the problems of high raw material cost and low strength, and achieve the effects of reduced production cost, high economic value, and improved coagulation strength and coagulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

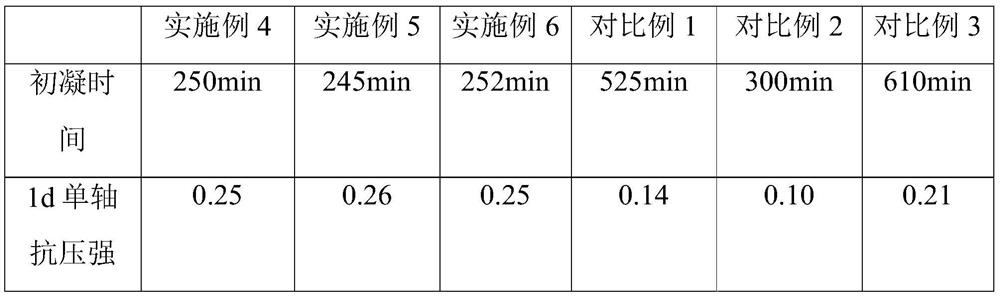

Examples

Embodiment 1

[0035] A meteeration of a meteorite, composed of components of the following mass parts:

[0036] 20 parts of silicate cement, 2 sulfoal saline cement clinkers, 5 modified gypsum, 60 parts of the mineral powder, 5 parts of limestone powder, 0.2 sodium silicate, and 2 additions.

[0037] Among them, the fineness of the silicate cement clinker is between 350-400;

[0038] The sulumide cement clinker is calcined by aluminum aluminum, limestone, gypsum and boric acid after calcination by 1300 ° C, and the powder grinding to a specific surface area ≥ 460m. 2 / kg is obtained, the mass ratio of the aluminum aluminum, limestone, gypsum and boric acid is 30: 45: 8: 1, and the content of alumina in the sulfur-aluminate cement clinker is 29%;

[0039] The external agent is composed of hydroxymethylcellulose, polyacrylamide, high-efficiency water reduction and polycarboxylate, a mass ratio of 2: 1: 1: 1; wherein the high-efficiency water reduction agent is 2: 1 by mass ratio of 2: 1. Calcium...

Embodiment 2

[0045] A meteeration of a meteorite, composed of components of the following mass parts:

[0046] 25 copies of silicate cement, 3 sulfoside cement clinkers, 8 modified gypsum, 65 parts of mineral powder, 8 pieces of limestone powder, 0.25 sodium silicate, and additives: 3 parts.

[0047] Among them, the fineness of the silicate cement clinker is between 350-400;

[0048] The sulfosulctate cement clinker is calcined by aluminum aluminum bauxite, limestone, gypsum and boric acid after calcination of 1350 ° C, powder grinding to a specific surface area ≥ 460m 2 / kg is obtained, the aluminum aluminum, limestone, gypsum and blend of boric acid is 36: 50: 15: 1.5, and the content of alumina in the sulfurate cement clinker is 32%;

[0049] Hydroxymethylcellulose sodium, polyacrylamide, high-efficiency water reducer, and polycarboxylate is composed of hydroxymethylcellulose, polyacrylamide, high-efficiency water reducer, and polycarboxylate; wherein the high-efficiency water reduction age...

Embodiment 3

[0055] A meteeration of a meteorite, composed of components of the following mass parts:

[0056] 30 parts of silicate cement, 4 copies of sulumate cement, 10 modified gypsum, 70 ore powder, 10 limestone powder, 0.3 sodium silicate, and 4 universal.

[0057] Among them, the fineness of the silicate cement clinker is between 350-400;

[0058] The sulfoside cement clinker is calcined by aluminum aluminum, limestone, gypsum and boric acid after calcination of 1400 ° C, powder grinding to a specific surface area ≥ 460m 2 / kg is obtained, the mass ratio of the aluminum aluminous, limestone, gypsum and boric acid is 42: 58: 20: 2, and the content of alumina in the sully aluminate cement clinker is 35%;

[0059] The external agent consists of a mass ratio of 3: 2: 2: 2: 2: polyacrylamide, high-efficiency water reducer, and polycarboxylate; wherein the high-efficiency water reduction is from a mass ratio of 3: 2. Calcium sulfate and sodium ligno sulfonate; polycarboxylate uses a modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com