A kind of glass suitable for uv curing process and preparation method thereof

A curing process and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of glass yellowing and transmittance, reduce the number of irradiation times, strong anti-irradiation ability, and color difference small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

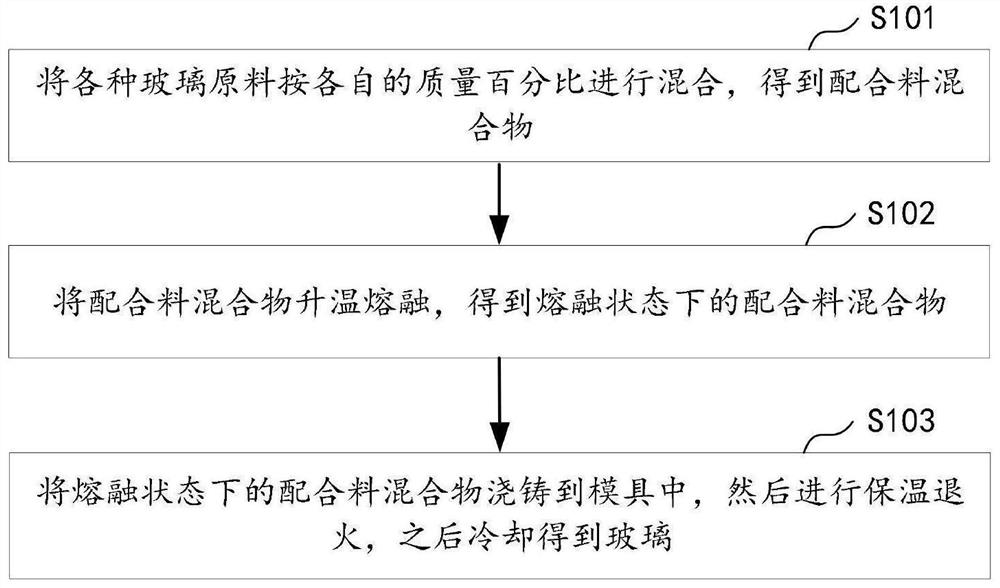

[0059] In Table 1, Table 2 and Table 3, commonly used glass raw materials such as oxides and carbonates, etc. were appropriately selected to have the compositions shown in the tables, and were weighed to obtain 150 g of the batch mixture; The batch mixture was placed in a platinum crucible, and the platinum crucible was placed in a silicon-molybdenum furnace, heated to 1650 °C, melted for 3 hours, homogenized and cast into a mold, kept at 620 °C for 1 hour annealing, and then followed by annealing. Furnace cooling to obtain block glass; the block glass is processed to obtain several pieces of thin glass with a size of 50mm×50mm×0.7mm, and the upper and lower surfaces are polished.

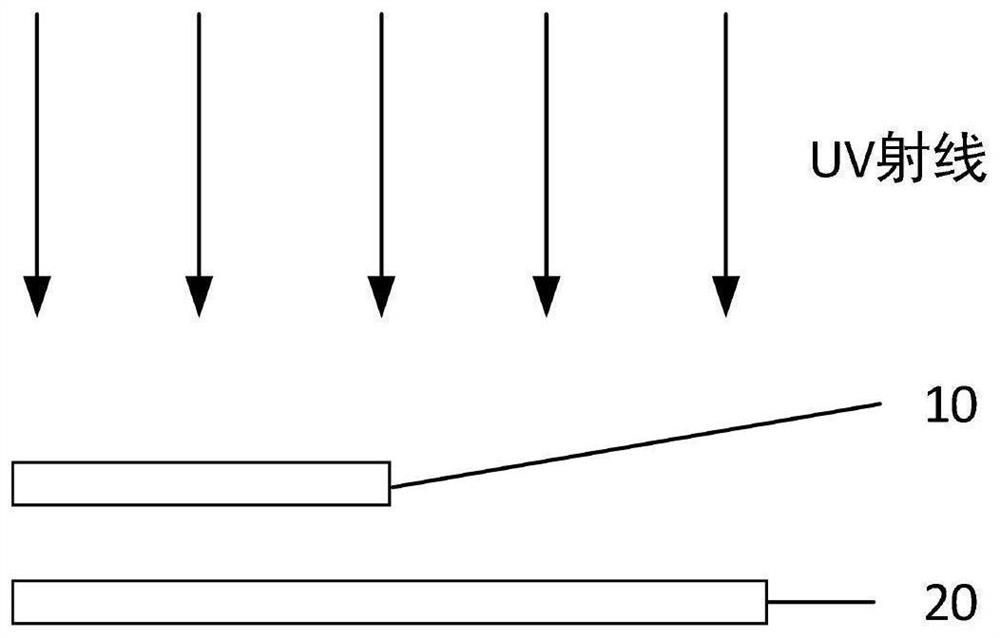

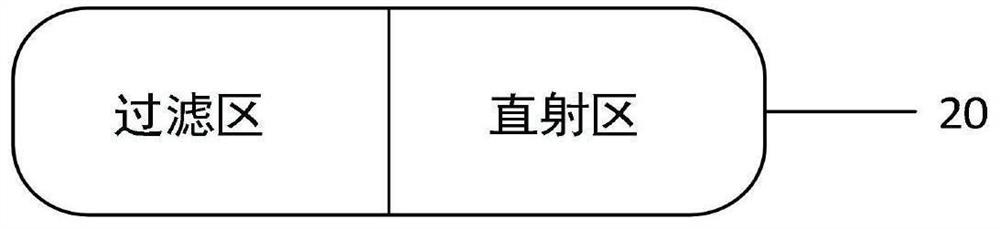

[0060] like figure 2 and image 3 As shown, the above-mentioned glass sample 20 is irradiated twice by a metal halide lamp, and the irradiation time is 5s each time, and the filter 10 is used to cover half of the glass sample 20 during irradiation, and the energy in the direct irradiation area fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com