Glass suitable for UV curing process and preparation method thereof

A curing process and glass technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of glass yellowing and transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

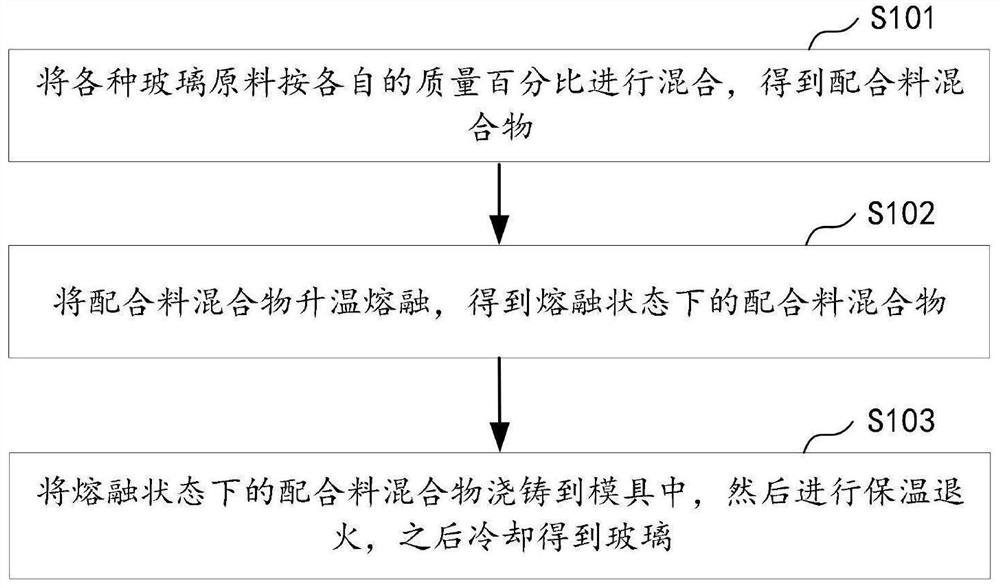

[0060] In Table 1, Table 2, and Table 3, commonly used glass raw materials such as oxides and carbonates, etc. are appropriately selected to have the composition shown in the table, and weighed to obtain 150 g of the batch mixture; then, the Put the batch mixture into a platinum crucible, put the platinum crucible into a silicon-molybdenum furnace, raise the temperature to 1650°C, and melt it for 3 hours, homogenize it and cast it into a mold, keep it at 620°C for 1 hour and anneal, then follow Cool the furnace to obtain block glass; process the block glass to obtain several pieces of thin glass with a size of 50mm×50mm×0.7mm and polished upper and lower surfaces.

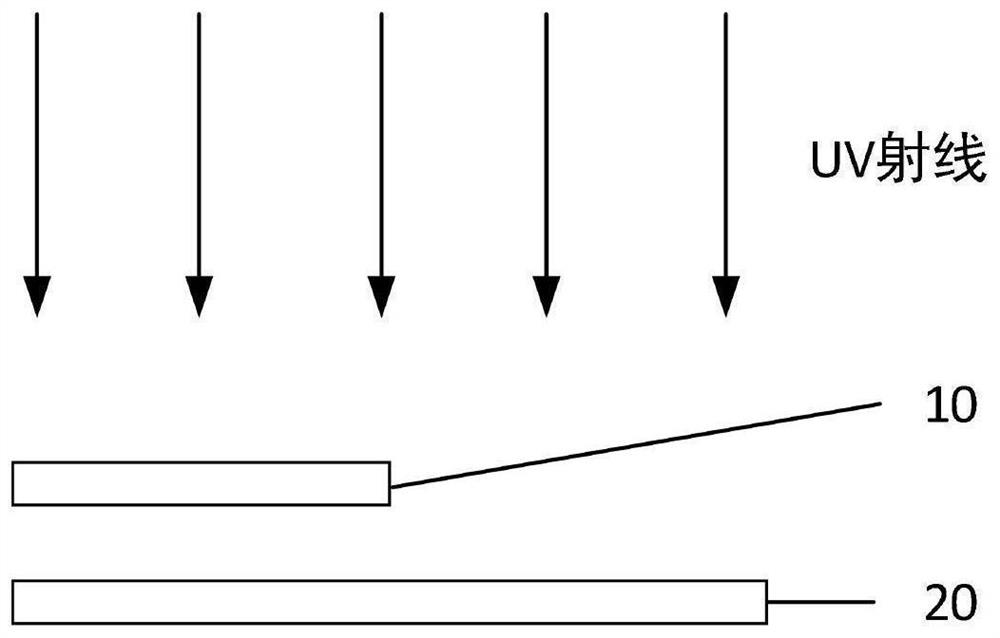

[0061] like figure 2 and image 3 As shown, metal halide lamps are used to irradiate the glass sample 20 twice, each time for 5 s, half of the glass sample 20 is covered with an optical filter 10 during irradiation, and the energy in the direct area of each irradiation is 2800mj / cm 2 , the total energy of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com