Composite nanofiltration membrane taking layered double hydroxides as modified templates and preparation method

A layered bimetallic and composite nanofiltration membrane technology, which is applied in the field of separation membranes, can solve the problems of reducing mechanical strength and the difficulty of modifying the modified support base membrane, so as to improve the separation performance, enhance the surface wrinkle rough structure, and reduce the transmission rate. The effect of mass resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

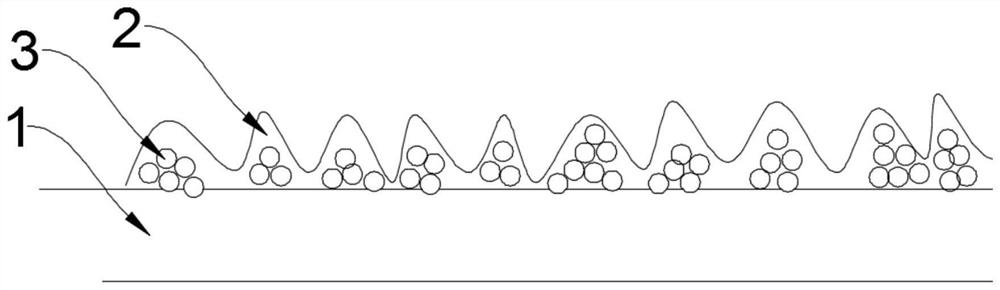

Image

Examples

preparation example Construction

[0020] This embodiment also proposes the preparation method of the composite nanofiltration membrane with the above-mentioned layered double metal hydroxide as a modified template, including the following steps:

[0021] S1, obtaining a layered double metal hydroxide, and modifying the surface of the layered double metal hydroxide with a modifier containing polyphenol molecules to obtain a modified layered double metal hydroxide.

[0022] In a preferred embodiment, the layered double metal hydroxide is obtained according to the following steps: disperse divalent metal salt, trivalent metal salt and precipitant in water, react at 120-180°C for 5-36 hours to obtain a layer double metal hydroxide.

[0023] Further preferably, the metal ion in the divalent metal salt is selected from one or more of magnesium ion, zinc ion, nickel ion, calcium ion, cobalt ion and manganese ion, and the divalent metal salt is selected from chloride salt, sulfate and one or more of nitrates; the con...

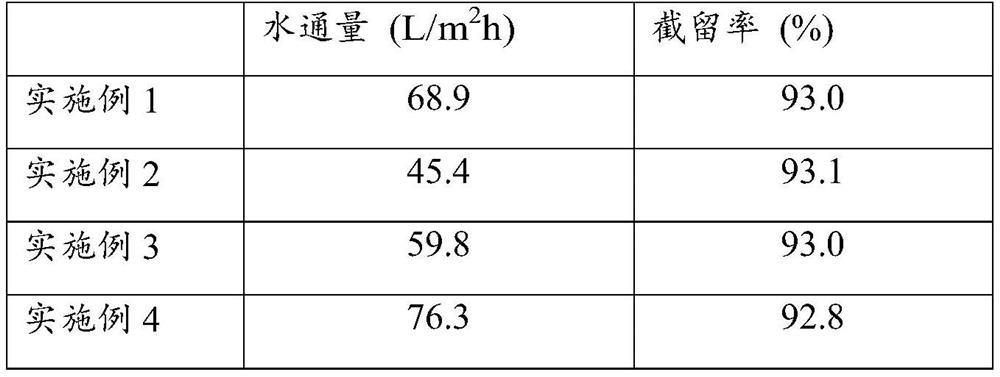

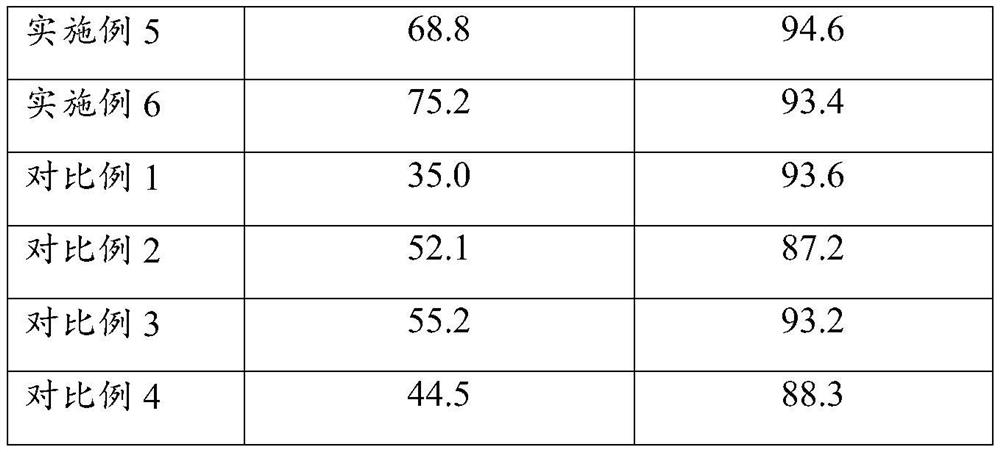

Embodiment 1

[0040] A kind of composite nanofiltration membrane provided by the present embodiment is prepared according to the following steps:

[0041] (1) Weigh 4.69mmol of magnesium chloride, 1.56mmol of aluminum chloride and 8.44mmol of urea, dissolve them in 32mL of deionized water, transfer them to an autoclave after ultrasonication, and react at 160°C for 6h. Centrifuge and wash to obtain layered double hydroxides (LDHs) powder. Disperse 0.03g LDHs powder evenly in 100mL deionized water, add 0.02g dopamine hydrochloride and 0.12g Tris, stir and react for 5h, centrifuge and wash to obtain modified LDHs powder.

[0042] (2) Disperse the modified LDHs powder in water, ultrasonically treat it for 5 min, then filter the uniformly dispersed aqueous solution of modified LDHs onto the polysulfone porous membrane to obtain a modified polysulfone porous membrane, and control the loading capacity of the modified LDHs as 0.4g / m 2 .

[0043] (3) The modified polysulfone porous membrane obtai...

Embodiment 2

[0047] The difference between the composite nanofiltration membrane provided in this example and Example 1 is that the load of modified LDHs is 0.2g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com