AgNWs-PDMS composite flexible conductive optical fiber micro lens and preparation method thereof

A composite flexible and composite conductive technology, which is applied in the medical field, can solve the problems of poor electrical conductivity and light guiding performance, PDMS optical fiber does not have optical fiber waveguide structure, and high resistivity of conductive hydrogel, and achieves low cost, simple preparation method, and high production efficiency. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

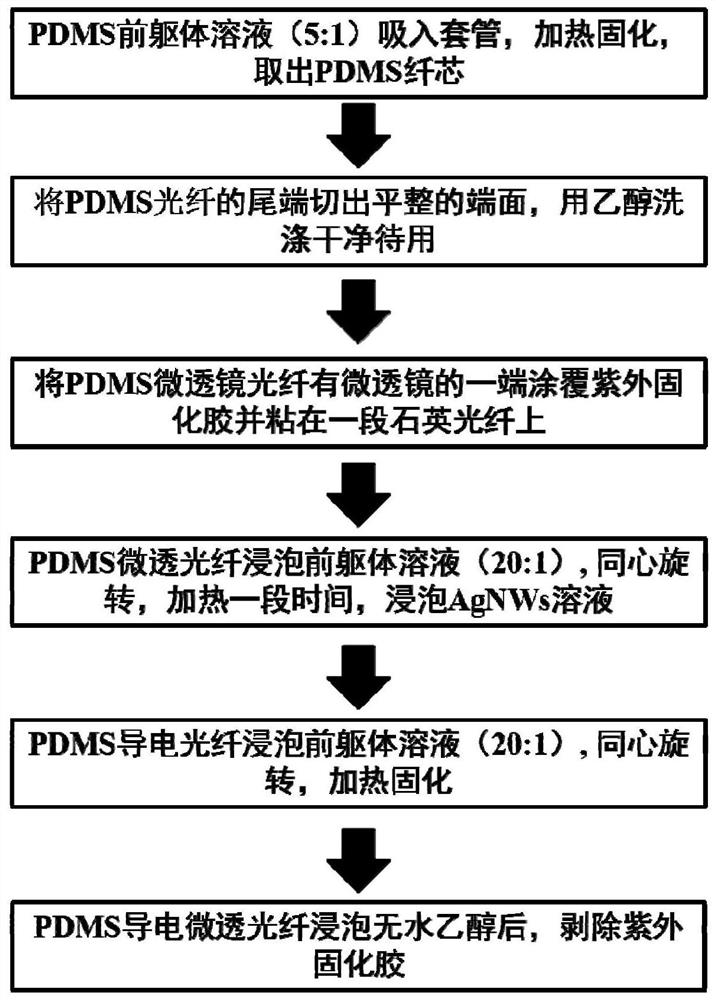

[0054] A kind of preparation method of AgNW-PDMS composite flexible conductive fiber optic microlens, comprises the following steps (can refer to figure 1 shown):

[0055] 1) Inhale the PDMS precursor solution into the sleeve (diameter 200 μm, length 5 cm), put it in an oven to heat and dry for curing treatment, the temperature of the curing treatment is 80 ° C, the curing treatment time is 40 minutes, and the curing is complete After taking it out, the PDMS fiber core is obtained; the PDMS precursor solution is a solution obtained by mixing the polydimethylsiloxane monomer and the curing agent uniformly and removing air bubbles in a vacuum; the polydimethylsiloxane monomer and the curing agent The mass ratio is 5:1.

[0056] 2) The tail end of the PDMS fiber core is cut off to form a flat end face, washed with ethanol, and then the PDMS fiber core is immersed in the PDMS precursor solution; the raw material for the synthesis of PDMS is the polydimethylsilane of Sylgard 184 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com