Multi-channel gyromagnetic filter magnetic circuit

A filter, multi-channel technology, applied in the direction of transformer/inductor core, circuit, transformer/inductor components, etc., can solve the problems of small current bearing capacity, small compensation coil frequency tuning and compensation range, and poor magnetic field uniformity. , to achieve the effect of improving the frequency compensation capability, increasing the compensation frequency modulation range, and reducing the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

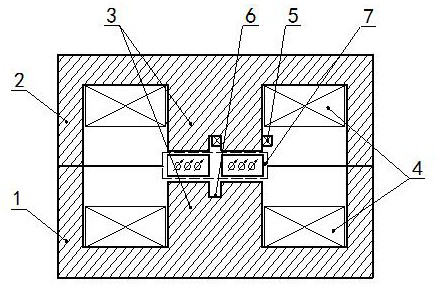

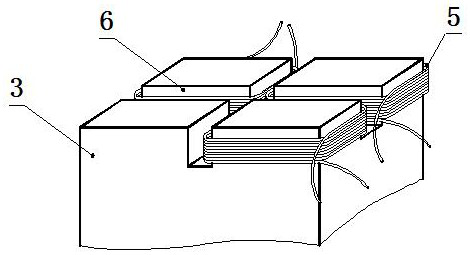

[0038] Example 1: X-Ku band rectangular magnetic pole four-channel integrated magnetic circuit

[0039] see figure 2 with 3 , X-Ku band rectangular magnetic pole four-channel integrated magnetic circuit: including lower magnetic circuit 1, upper magnetic circuit 2, magnetic pole column 3 of upper and lower magnetic circuits, main coil 4, compensation coil 5, coil installation slot 6 and multi-channel resonance circuit 7. The coil installation groove 6 is located at the end faces of the magnetic pole posts 3 of the upper and lower magnetic circuits and is vertical to the end faces. The end faces of the magnetic pole posts 3 of the upper and lower magnetic circuits are respectively divided into four parts, and the compensation coil 5 is set in the coil installation groove 6. The number of compensation coils 5 is 3. In the present embodiment, the 3 compensation coils 5 are respectively drawn out and then connected to respective current exciters, so that independent frequency co...

Embodiment 2

[0043] Embodiment 2: S-C band cylindrical magnetic pole four-channel integrated magnetic circuit

[0044] see figure 2 , Figure 4 , S-C band rectangular magnetic pole four-channel integrated magnetic circuit: including a lower magnetic circuit 1, an upper magnetic circuit 2, a magnetic pole 3 of the upper and lower magnetic circuits, a main coil 4, a compensation coil 5, a coil installation slot 6 and a multi-channel resonance circuit 7; The coil mounting groove 6 is located at the end face of the magnetic pole post 3 of the upper and lower magnetic circuit and is vertical to the end face, and the end face of the magnetic pole post 3 of the upper and lower magnetic circuit is divided into four parts respectively, and the compensation coil 5 is set in the coil mounting groove 6 to compensate The number of coils 5 is 4. In this embodiment, the 4 compensation coils 5 are respectively drawn out and connected to respective current actuators;

[0045] The four-way resonant circu...

Embodiment 3

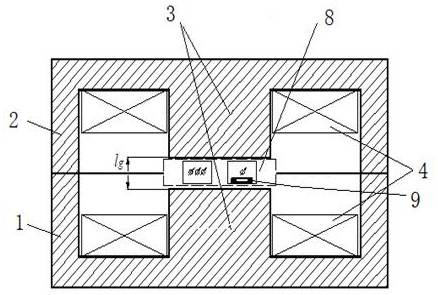

[0046] Embodiment 3: S-C band rectangular magnetic pole column two-channel different-frequency tracking magnetic circuit

[0047] see figure 2 , Figure 5 , S-C band rectangular magnetic pole two-channel different-frequency tracking magnetic circuit: including lower magnetic circuit 1, upper magnetic circuit 2, magnetic pole column 3 of the upper and lower magnetic circuit, main coil 4, compensation coil 5, coil installation slot 6 and two resonant circuits 7. The coil installation groove 6 is located at the end faces of the magnetic pole posts 3 of the upper and lower magnetic circuits and is vertical to the end faces, and the end faces of the magnetic pole posts 3 of the upper and lower magnetic circuits are respectively divided into two parts, and the compensation coil 5 is set in the coil installation groove 6, The number of compensation coils 5 is two, which are respectively located in the coil installation grooves of the same partition of the upper and lower magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com