Breathable and waterproof multi-response fabric sensor

A fabric sensor, breathable and waterproof technology, used in instruments, scientific instruments, surface/boundary effects, etc., can solve problems such as performance degradation, achieve mild and controllable reaction conditions, excellent photothermal response performance, strain and temperature sensing performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of MXene:

[0039] Mix 1 g of LiF and 20 ml of dilute hydrochloric acid (9M) for 15 minutes, then add 1 g of Ti 3 AlC 2 The powder is slowly added to it, and stirring is continued at 35 ℃ for 24 h until the etching is complete. Then, the obtained MXene mixture was centrifuged and washed for 5 min at 3500 rpm with deionized water until the pH of the supernatant was greater than or equal to 6. The supernatant and the precipitate were mixed ultrasonically for 1 hour and centrifuged at 3500 rpm for 1 hour to collect the upper black liquid, which is the MXene colloidal solution. figure 2 In the XRD patterns of MXene and MAX prepared for this example, it can be seen that the Al layer is completely etched and the MXene is completely etched.

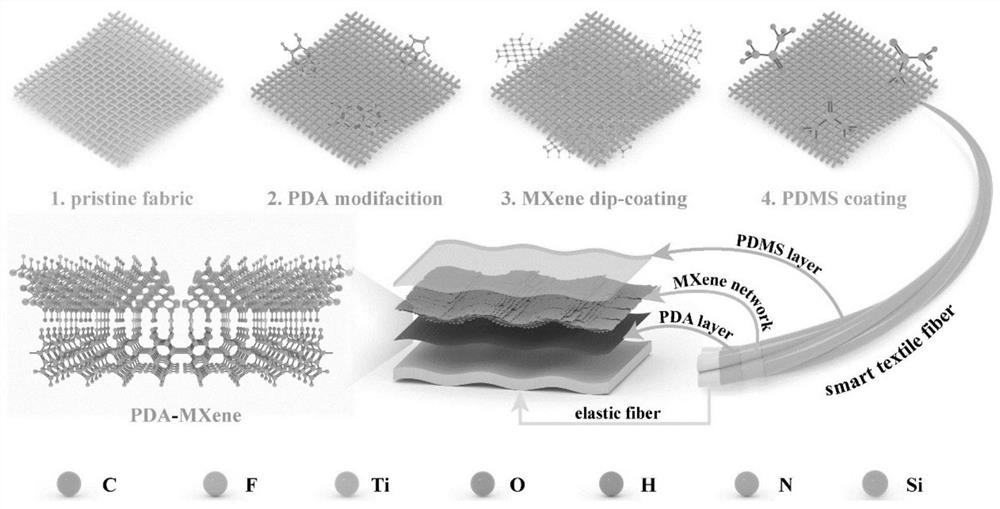

[0040] (2) Preparation of multifunctional MXene fabric sensor:

[0041] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexible elastic fabric into the above solu...

Embodiment 2

[0044] (1) Preparation of MXene:

[0045] The preparation process and conditions are the same as the step (1) of Example 1.

[0046] (2) Preparation of multifunctional MXene fabric sensor:

[0047] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexible elastic fabric into the above solution and react with magnetic stirring for 6 h. After that, take it out and wash it with deionized water and put it in a 40℃ oven. Dry for 12 h. The PDA modified elastic fabric was immersed in the MXene colloidal solution with a concentration of 5 wt.% for 10 minutes, the fabric was taken out and dried at 40°C for 30 minutes, and then the above-mentioned dipping and drying process was repeated twice to make MXene immersed 3 times Fabric. In order to give the fabric super-hydrophobic properties and maintain the inherent breathability of the fabric itself, the fabric immersed in MXene 3 times was immersed in a 1 wt.% PDMS n-heptane solut...

Embodiment 3

[0050] (1) Preparation of MXene:

[0051] The preparation process and conditions are the same as the step (1) of Example 1.

[0052] (2) Preparation of multifunctional MXene fabric sensor:

[0053] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexible elastic fabric into the above solution and react with magnetic stirring for 6 h. After that, take it out and wash it with deionized water and put it in a 40℃ oven. Dry for 12 h. The PDA modified stretch fabric was immersed in a MXene colloidal solution with a concentration of 5 wt.% for 10 minutes, the fabric was taken out and dried at 40°C for 30 minutes, and then the immersion and drying process was repeated 4 times to make a fabric impregnated with MXene 5 times . In order to give the fabric super-hydrophobic properties and maintain the inherent breathability of the fabric itself, the fabric impregnated with MXene for 5 times was immersed in a 1wt.% polydimethylsil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com