Nano-porous copper oxide, preparation method thereof and application thereof in garbage stink

A nanoporous, copper oxide technology, applied in the field of adsorption materials, can solve problems such as poor adsorption effect, and achieve the effect of enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of nanoporous copper oxide, comprising the steps of:

[0031] (1) Stir 20g copper acetate and 40g benzene at 60°C and 4000rpm to form a first mixed solution, which is in a suspension state; mix 5mL isopropanol with 0.5mL deionized water Uniformly form a second mixed solution, add the second mixed solution to the first mixed solution, heat to 80°C, and react for 2 hours under stirring at a speed of 500rpm. During the reaction, nano-clusters are gradually formed, and then evaporated at 90°C 6h, obtain the precursor after evaporating to dryness;

[0032] (2) The temperature of the precursor was raised to 300° C. for 3 h at a temperature increase rate of 1° C. / min in a high-temperature furnace, and the precursor was calcined at a constant temperature for 3 hours. After cooling, nanoporous copper oxide was obtained.

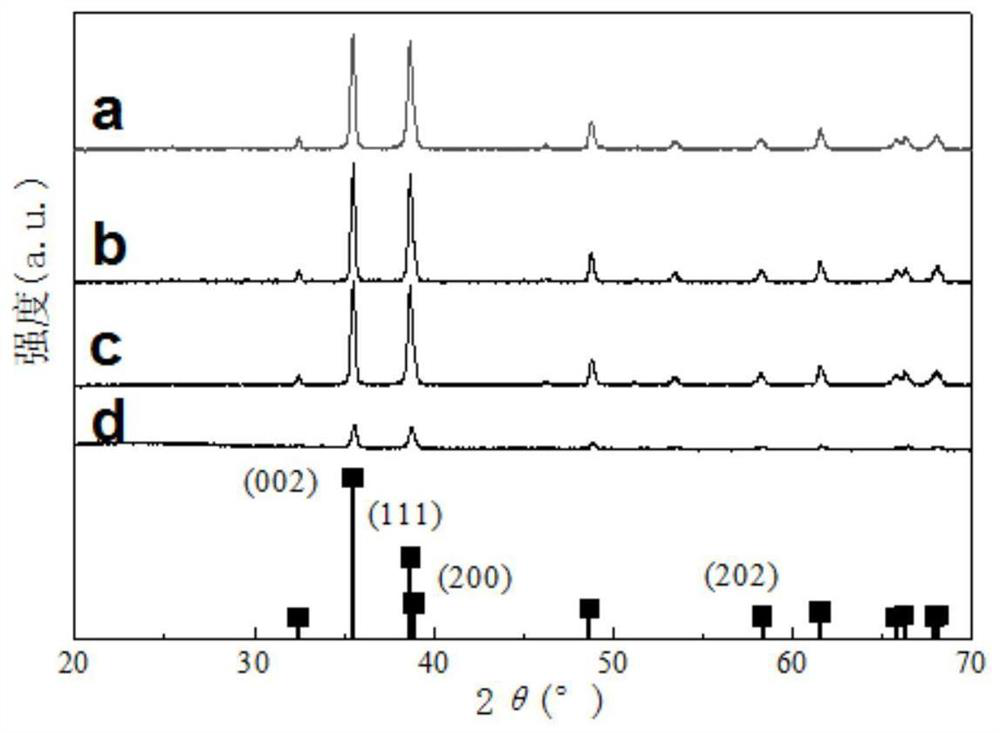

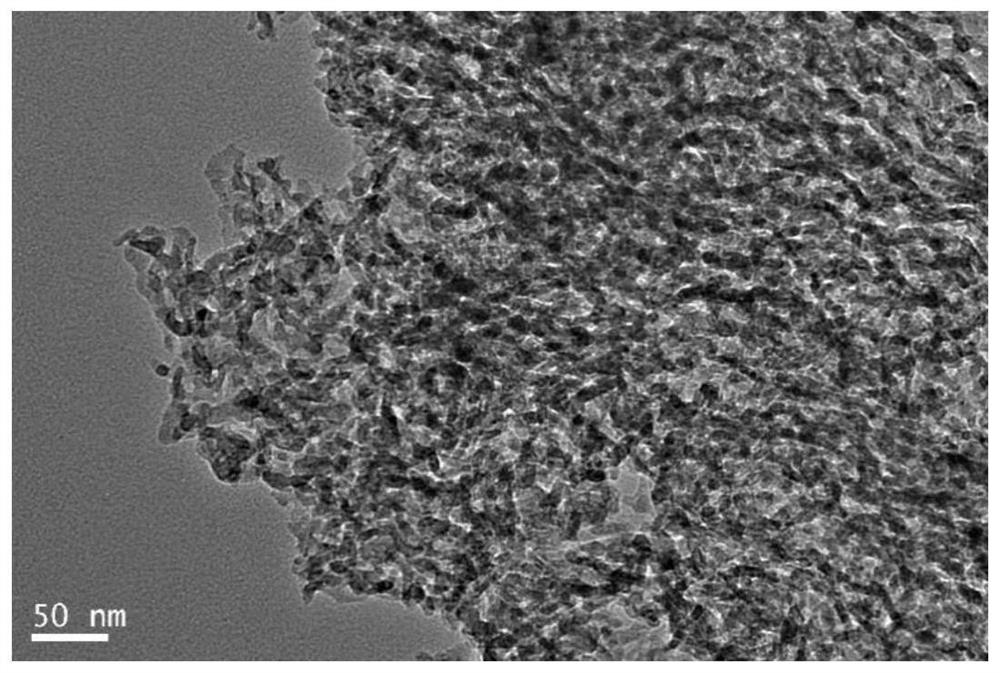

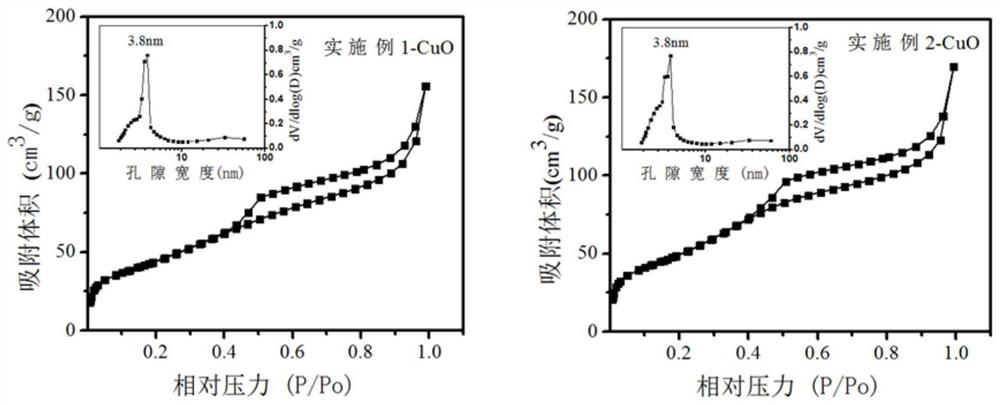

[0033] The nanoporous copper oxide of the present embodiment is characterized by X-ray diffraction, and the XRD figure is shown in 1a, wh...

Embodiment 2

[0038] A preparation method of nanoporous copper oxide, comprising the steps of:

[0039] (1) Stir 30g copper acetate and 60g ethylbenzene at 80°C and 4000rpm to form a first mixed solution; the state of the first mixed solution is a suspension; mix 8mL ethanol and 6mL deionized water evenly to form The second mixed solution, adding the second mixed solution to the first mixed solution, heating to 120° C. and reacting for 3 hours under stirring at a speed of 1000 rpm, gradually forming nano-clusters during the reaction, and then evaporating at 120° C. for 10 hours, Obtain the precursor after evaporating to dryness;

[0040] (2) The precursor was calcined at a constant temperature of 400° C. for 5 hours at a heating rate of 3° C. / min in a high-temperature furnace, and the nanoporous copper oxide was obtained after cooling.

[0041] The nanoporous copper oxide of this embodiment is characterized by X-ray diffraction, and the XRD figure is shown in 1b, which is obtained by figu...

Embodiment 3

[0044] A preparation method of nanoporous copper oxide, comprising the steps of:

[0045] (1) Stir 40g copper acetylacetonate and 80g toluene at 70°C and 4000rpm to form a first mixed solution, which is a homogeneous solution; mix 10mL butanol and 8mL deionized water evenly to form a second mixed solution solution, adding the second mixed solution to the first mixed solution, heating to 100°C and stirring at a speed of 2000rpm for 4h, then evaporating at 100°C for 8h, and obtaining the precursor after evaporation to dryness;

[0046] (2) The temperature of the precursor is raised to 500° C. for 8 hours at a temperature increase rate of 5° C. / min in a high-temperature furnace, and the precursor is calcined at a constant temperature for 8 hours, and the nanoporous copper oxide is obtained after cooling.

[0047] The nanoporous copper oxide of this embodiment is characterized by X-ray diffraction, and the XRD figure is shown in 1c, which is obtained by figure 1 c, it can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com