Protective mask and preparation method thereof

A mask and porous membrane technology, applied in protective equipment, protective clothing, separation methods, etc., can solve problems such as the decline in filtration efficiency of protective masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the protective mask described in the above technical solution, comprising the following steps:

[0041] According to the lamination sequence, each layer of material is laminated and then hot-rolled to obtain the composite layer of the main body of the protective mask;

[0042] According to the size of the main body of the protective mask, the composite layer of the main body of the protective mask is cut to obtain the main body of the protective mask;

[0043] The main body of the protective mask is connected with the ear loop to obtain the protective mask.

[0044] According to the invention, each layer of materials is laminated according to the lamination sequence and then hot-rolled to obtain the composite layer of the main body of the protective mask.

[0045] In the present invention, the materials of each layer are consistent with the structural materials of each layer of the main body of the protective...

Embodiment 1

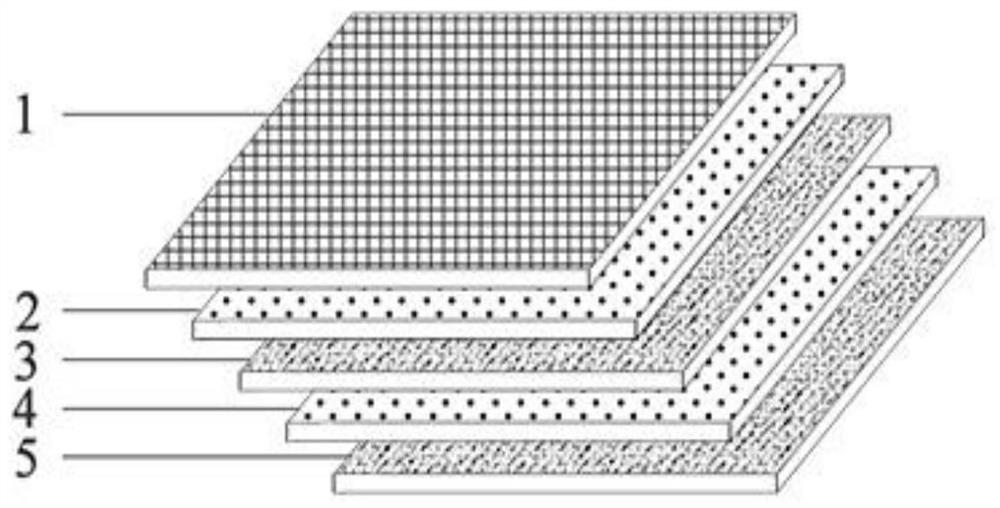

[0053] According to the order from the outside to the inside, the fabric layer, the hot-melt fiber web, the first porous membrane material layer, the bi-component fabric layer, the second porous membrane material layer and the non-woven fabric layer are stacked in sequence, wherein the fabric layer Polyester filament fabric is used, the warp and weft are both 36.1tex, the warp density is 190 / 10cm, and the weft density is 160 / 10cm; the first porous membrane material layer is polytetrafluoroethylene porous membrane, with an average The pore size is 3.9 μm, and the porosity is 86%; the hot-melt fiber web is a polyamide fiber web with a melting point of 130°C, and the weight is 10g / cm 2 ;The two-component fabric layer is a fiber net formed by mixing PET fibers with a melting point of 230°C and PP fibers with a melting point of 130°C, wherein the mass ratio of PET to PP is 7:3, and the weight of the two-component fabric layer is 45g / cm 2 The second porous membrane material layer ...

Embodiment 2

[0059] According to the order from the outside to the inside, the fabric layer, the hot-melt fiber web, the first porous membrane material layer, the bi-component fabric layer, the second porous membrane material layer and the non-woven fabric layer are stacked in sequence, wherein the fabric layer It adopts two-component spunbond nonwoven fabric, which is composed of PET fiber with a melting point of 230°C and PP fiber with a melting point of 130°C, and the weight is 100g / cm 2 The first porous membrane material layer is a polytetrafluoroethylene porous membrane with an average pore size of 3.9 μm and a porosity of 86%; the hot-melt fiber web is a polyamide fiber web with a melting point of 130° C. and a grammage of 10 g / cm 2 ;The two-component fabric layer is a fiber net formed by mixing PET fibers with a melting point of 230°C and PP fibers with a melting point of 130°C, wherein the mass ratio of PET to PP is 7:3, and the weight of the two-component fabric layer is 45g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Inhalation resistance | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com