Inner protective gas rod for welded pipe welding

A shielding gas and welded pipe technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of pipe cracking, stress corrosion, stress angle, etc., and achieve the effect of avoiding collapse and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

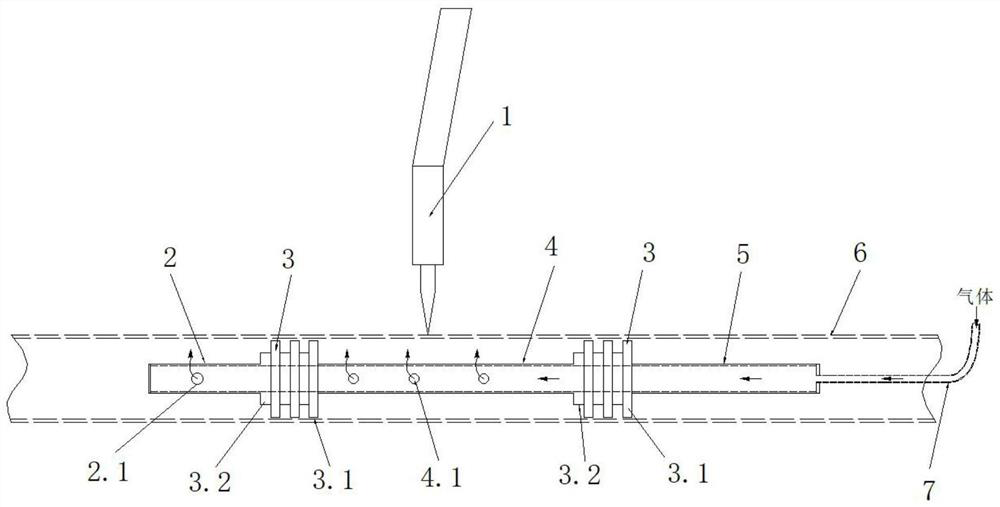

[0026] see figure 1 , an inner protective gas rod for welded pipe welding, comprising a terminal rod section 2, a plug 3 and an air outlet rod section 4, the air outlet rod section 4 is provided with a plurality of air outlet holes 4.1 and two ends are respectively provided with plugs 3 , through two plugs 3 and the inner wall of the welded pipe 6 to form an air pressure chamber covering the outside of the air outlet rod section 4; the end rod section 2 is provided with an end air hole 2.1 and the end rod section 2 communicates with the air outlet rod section 4 to enter the air outlet The gas in the rod section 4 is discharged through the air outlet hole 4.1 and the terminal air hole 2.1.

[0027] The material of the welded pipe in this embodiment is titanium, and the inner shielding gas rod in this embodiment is for welding protection of titanium pipes. Titanium is an easily oxidizable metal, and the terminal air hole 2.1 is set at the end rod section 2 to prevent the titaniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com