Copper/ steel composite material connecting method for preset joint

A connection method and composite material technology, applied in the field of copper/steel composite material connection, can solve problems such as failure of welded structures, reduction of joint strength, etc., and achieve the effect of reducing welding difficulty, reducing the difference in thermophysical properties, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

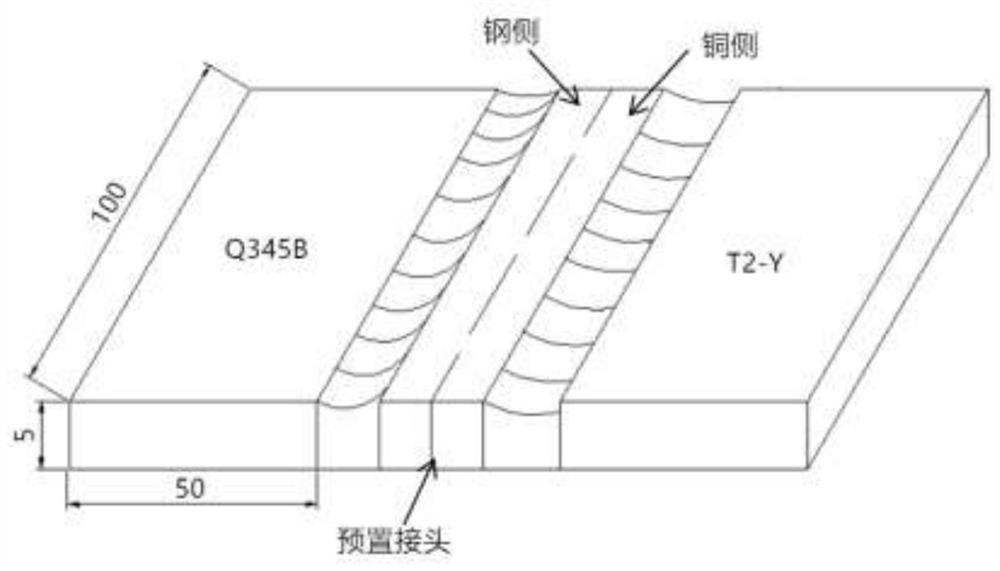

Embodiment 1

[0034] Step 1. Prepare pre-set joints with φ1.2mm CHW50C6 carbon steel welding wire and S211 silicon bronze welding wire. The welding robot is used to complete the additive preparation of the preset joint. The joint specification is 100×5×5mm, and each material is surfacing three layers, and each layer of welding bead must be polished with a wire brush to prevent inclusion. The specific additive preparation parameters are: ① Preparation of steel side preset joint: welding current is 190A, welding voltage is 21V, welding speed is 5mm / s, volume fraction is 90% Ar + volume fraction is 10% CO 2 The total volume percentage of the above components is 100%, and the gas flow rate is 15L / min; ②The preparation of the copper side preset joint: welding current is 210A, welding voltage is 22V, welding speed is 4mm / s, and inert shielding gas is the volume The ratio is 99.99% pure argon, and the flow rate is 15L / min.

[0035] Step 2: Clean the test board before welding, including mechanical pol...

Embodiment 2

[0038] Step 1. Prepare pre-set joints with φ1.2mm CHW50C6 carbon steel welding wire and S211 silicon bronze welding wire. A welding robot is used to complete the additive preparation of the preset joint. The joint specification is 100×5.5×5mm, and each material is surfacing three layers, and each layer of weld bead must be polished with a wire brush to prevent inclusion. The specific additive preparation parameters are: ① Preparation of the steel side preset joint: welding current is 200A, welding voltage is 22V, welding speed is 5.5mm / s, volume fraction is 90% Ar + volume fraction is 10% CO 2 The total volume percentage of the above components is 100%, and the gas flow rate is 16L / min; ②Preparation of the copper side preset joint: welding current is 220A, welding voltage is 23V, welding speed is 4.5mm / s, and inert shielding gas is Pure argon with a volume percentage of 99.99% and a flow rate of 16L / min.

[0039] Step 2: Clean the test board before welding, including mechanical p...

Embodiment 3

[0042] Step 1. Prepare pre-set joints with φ1.2mm CHW50C6 carbon steel welding wire and S211 silicon bronze welding wire. A welding robot is used to complete the additive preparation of the preset joint. The joint specification is 100×6.5×5mm, and each material is surfacing three layers. Each layer of weld bead must be polished with a wire brush to prevent inclusion. The specific additive preparation parameters are: ① Preparation of the steel side preset joint: welding current is 205A, welding voltage is 23.5V, welding speed is 6.5mm / s, volume fraction is 90% Ar + volume fraction is 10% CO 2 The total volume percentage of the above components is 100%, and the gas flow rate is 16L / min; ②Preparation of the copper side preset joint: welding current is 235A, welding voltage is 25V, welding speed is 5mm / s, and inert shielding gas is the volume The percentage of pure argon is 99.99%, and the flow rate is 16L / min.

[0043] Step 2: Clean the test board before welding, including mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com