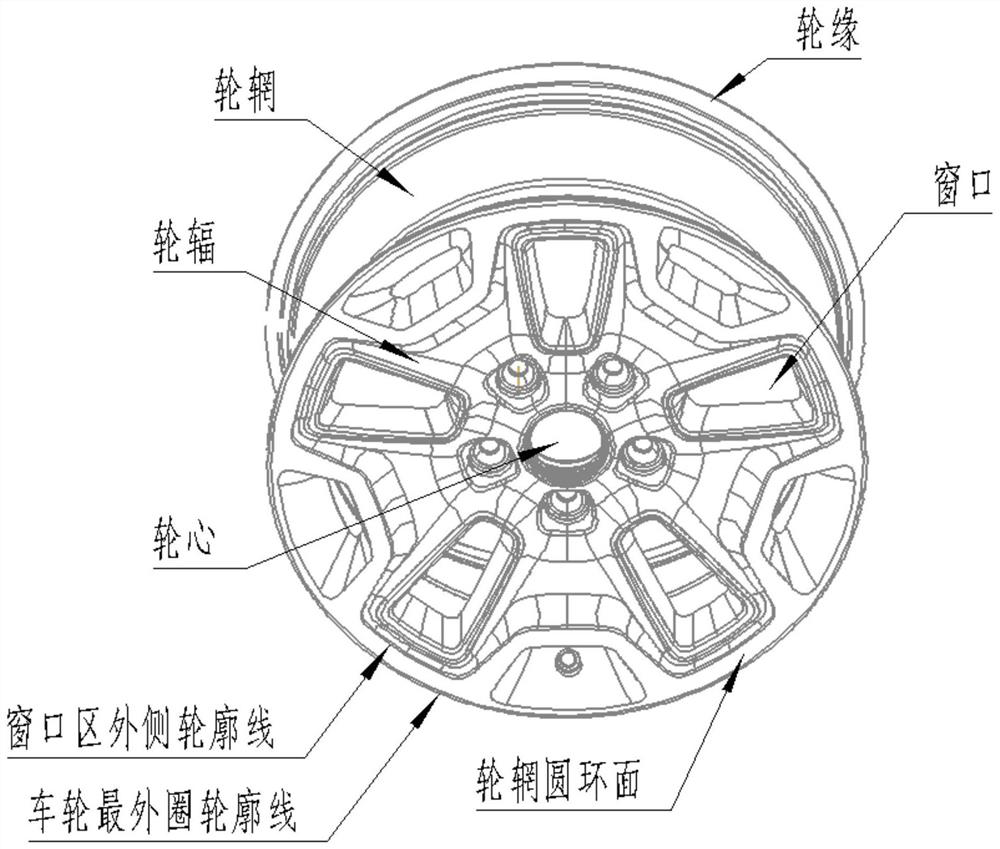

Rapid wheel progressive solidification forming device and method based on multiple lift tubes

A molding device and wheel technology, applied in the field of casting, can solve problems such as uncontrollable filling time, uncontrollable solidification sequence, and unsmooth gas discharge, so as to eliminate shrinkage defects, accelerate cooling speed and cooling effect, and smooth flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

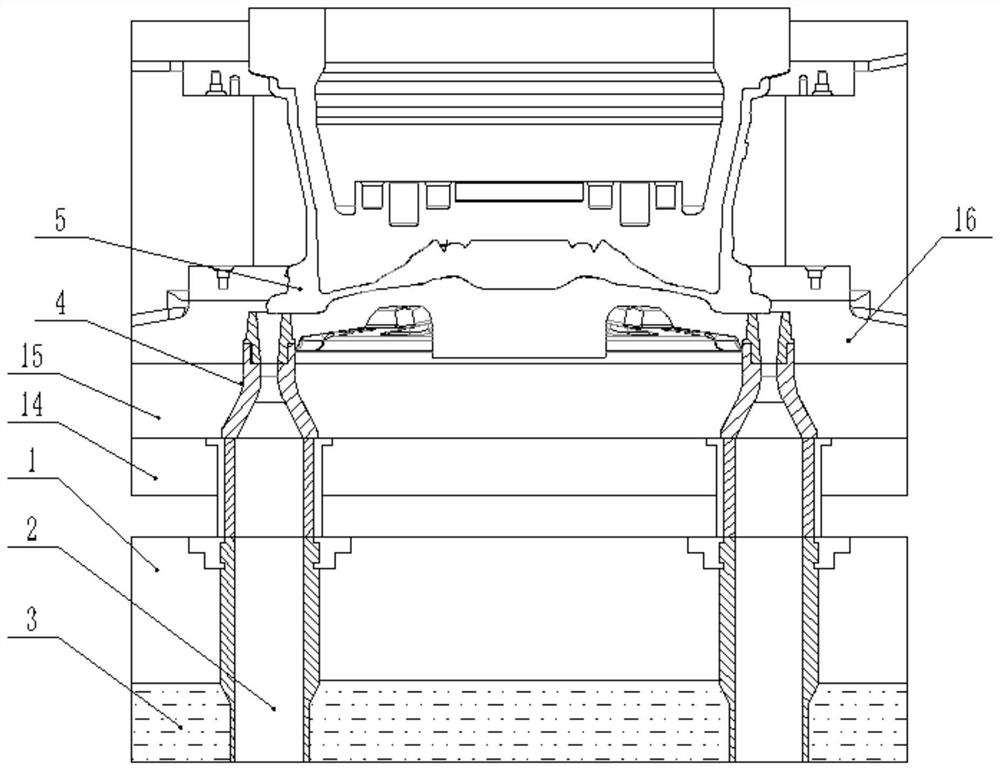

Method used

Image

Examples

Embodiment 1

[0063] Using 2 risers and gates, the mass percentage of the metal melt used is as follows: Si: 5-9%, Mg: 0.3-0.5%, Zr: 0.01-0.02%, B: 0.005-0.007%, RE: 0.002 ~0.005%, Fe: 0.05~0.15%, Mn: 0.05~0.1%, Ti: 0.08~0.14%, and the rest are Al and unavoidable impurities.

[0064] (1) Lifting liquid: Pressurize the aluminum liquid in the holding furnace through a high-pressure gas source, so that the aluminum liquid rises to the gate position along the liquid rising pipe under pressure. The pressure increasing speed at this stage is 3.5kPa / s, Pressure increased to 20kPa;

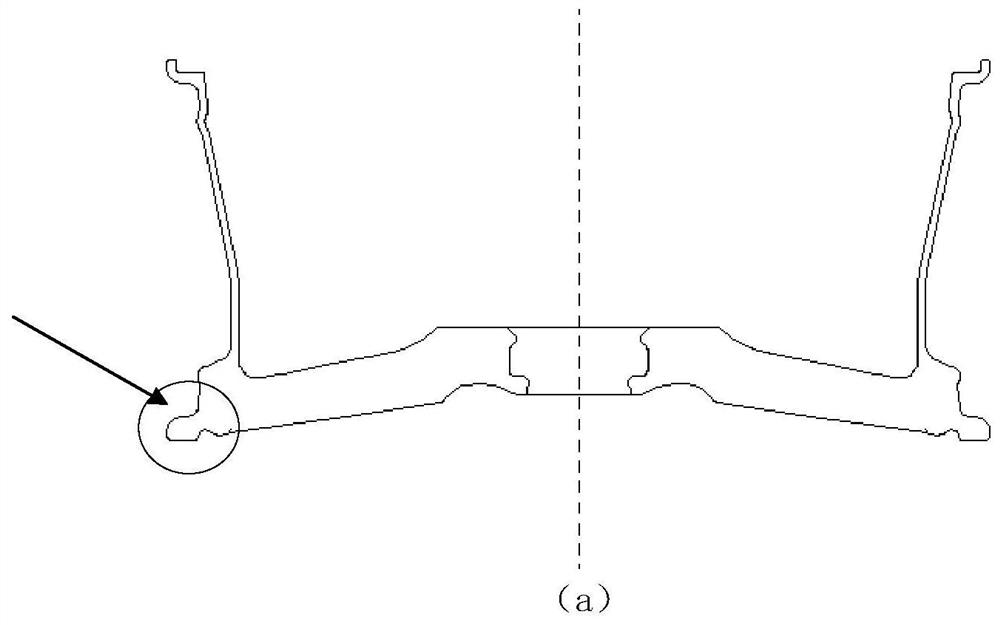

[0065] (2) Mold filling: Continue to increase the pressure so that the molten aluminum enters the cavity through the gate. The first stage increases the pressure at a speed of 0.2kPa / s and takes 1.8s to fill the molten metal smoothly. image 3 The area indicated by the arrow b, then enters the second stage and then quickly fills the mold at a boosting speed of 0.66kPa / s until the cavity is full;

[0066] (3) Crystall...

Embodiment 2

[0069] Using 4 risers and gates, the mass percentage of the metal melt used is as follows: Si: 5-9%, Mg: 0.3-0.5%, Zr: 0.01-0.02%, B: 0.005-0.007%, RE: 0.002 ~0.005%, Fe: 0~0.15%, Mn: 0.05~0.1%, Ti: 0.08~0.14%, and the rest are Al and unavoidable impurities.

[0070] (1) Lifting liquid: Pressurize the aluminum liquid in the holding furnace through a high-pressure gas source, so that the aluminum liquid rises to the gate position along the liquid rising pipe under pressure. The pressure increasing speed at this stage is 3.5kPa / s, Pressure increased to 20kPa;

[0071] (2) Mold filling: Continue to increase the pressure so that the molten aluminum enters the cavity through the gate. The first stage increases the speed at 0.15kPa / s, and the time is 2.2s, so that the metal melt can be filled smoothly image 3 The area indicated by the arrow b, then enters the second stage and then quickly fills the mold at a boosting speed of 0.92kPa / s until the cavity is full;

[0072] (3) Cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com