Cooling bed rack control method

A control method and cooling bed technology, applied in cooling bed, tail end control, manufacturing tools, etc., can solve the problems of destroying steel bar tailings cooling bed rack, increasing labor intensity of workers, unable to identify steel bar tailings and throwing steel. , to avoid the phenomenon of flying and the loss of materials and energy, reduce the labor intensity of workers, and reduce the processing time of refurbishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

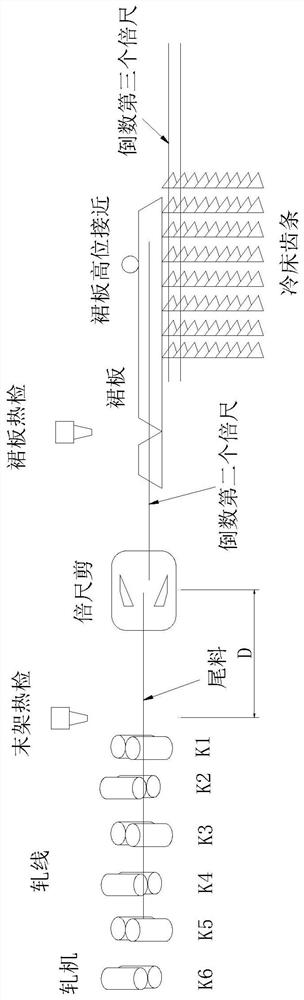

[0029] like figure 1 As shown, the cooling bed rack control method includes the following steps:

[0030] a. Obtain the length L of the steel tailings when the steel tailings hit the rack; obtain the length L of the steel tailings according to the impact of the racks during the previous steel throwing process.

[0031] b. Obtain the position S of the steel tailings on the rolling line when the length of the steel tailings is L; the specific steps include:

[0032] (1) According to the length L of the steel tailings, calculate the time T of the steel tailings running on the rolling line, T=(L-D) / V, where V is the linear speed of the rolling mill, and D is the thermal detection time of the end frame the distance of the ruler;

[0033] (2) Detect the time t1, t2, t3, ..., ti required by the main PLC to detect the time t1, t2, t3, ..., ti for the steel bars on the rolling line from leaving each rolling mill to the thermal inspection of the last frame; that is, the need for the s...

Embodiment 2

[0044] like figure 1 As shown, the cooling bed rack control method includes the following steps:

[0045] a. According to the impact of the rack in the process of throwing steel bars in the past, the length L of the steel tailings when the steel tailings hit the rack is 50m;

[0046] b. Obtain the position S of the steel tailings on the rolling line when the length of the steel tailings is 50m; the specific steps include:

[0047] (1) According to the length of the rebar tailings of 50m, calculate the time T of the rebar tailings running on the rolling line, T=(L-D) / V=(50-24) / 14≈1.86s; where V=14m / s, is the linear speed of the rolling mill; D=24m, is the distance from the thermal detection of the last frame to the double-length shear;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com