Self-repairing concrete anti-collision wall

A self-repairing concrete technology, which is applied in building maintenance, roads, construction, etc., can solve the problems of reducing the use effect of anti-collision walls and driving safety, concrete spalling damage, and untimely repair of cracks, etc., so as to reduce manual repair costs and environmental protection. The harm is small and the effect of reducing the cost of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0018] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

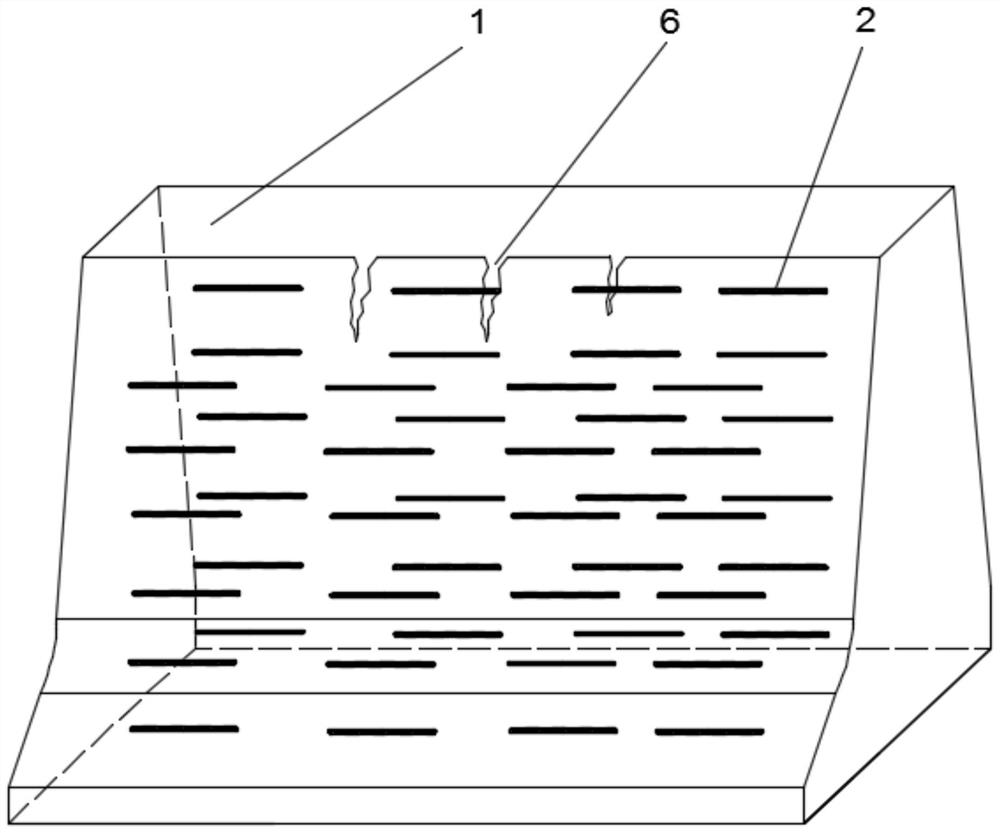

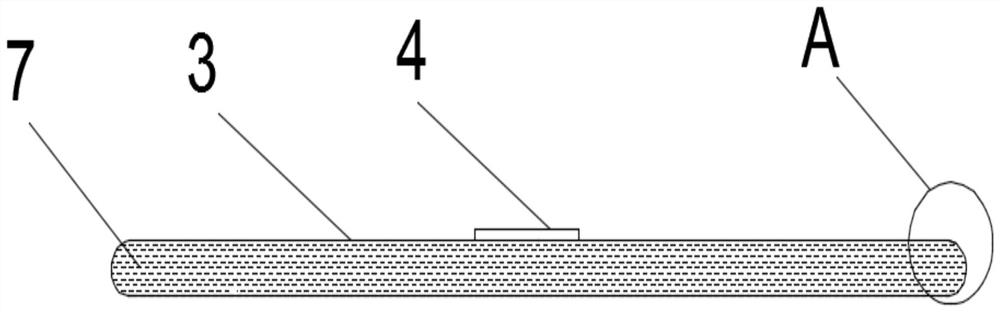

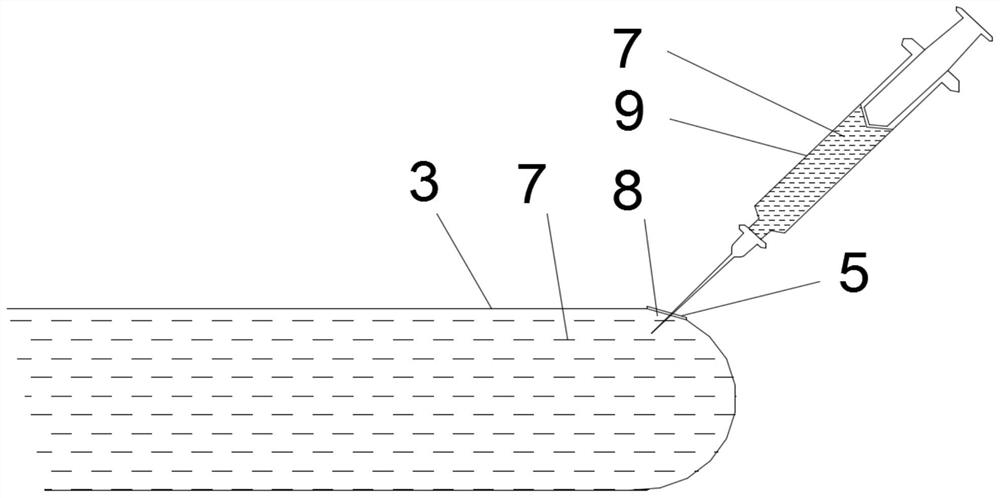

[0019] 1 is the anti-collision block, 2 is the self-repairing component, 3 is the glass tube, 4 is the sensor, 5 is the epoxy resin, 6 is the crack, 7 is the polyurethane repair agent, 8 is the injection port, and 9 is the syringe.

[0020] combine figure 1 , figure 2 , image 3 As shown, a self-repairing concrete anti-collision wall includes anti-collision blocks and self-repairing components installed in the anti-collision blocks; the self-repairing components include glass tubes, polyurethane repair agents in the glass tubes, and sensors installed on the glass tubes ; The glass tube is airtight, and the polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com