Waterborne fluorocarbon modified acrylic polyurethane coating

An acrylic polyurethane, water-based fluorocarbon technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, reflective/signal coatings, etc., can solve the problem that steel pipes are easily affected by sunlight, complex structures of rails and linear motors, and pipeline structures. and complication of composition to achieve the effect of light weight, long service life and good reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A water-based fluorocarbon modified acrylic polyurethane coating, comprising A component and B component, the ratio of the A component to the B component is 3:1~10:1, wherein, the A component is set according to the following mass fraction Components:

[0089] Waterborne fluorocarbon modified acrylic resin (48%) 45%~65%

[0091] Titanium dioxide 15%~25%

[0092] Defoamer 0.2%~1%

[0093] Wetting and dispersing agent 0.3%~0.8%

[0094] Water-based rheology additive 0.1%~0.6%

[0095] Bactericidal preservative 0.3%~0.6%

[0096] Antifungal agent 0.4%~0.8%

[0097] Glass microspheres 3%~15%

[0098] Ceramic microspheres 5%~15%

[0099] Deionized water 1%~15%

[0100] Coalescing agent 2%~5%

[0101] pH regulator 0.3%~0.6%;

[0102] The B component is HDI dimer / trimer, alcohol ether and alcohol ester solvents.

[0103] In this embodiment, the water-based fluorocarbon-modified propylene resin is a low-viscosity resin with hydroxyl gr...

Embodiment 2

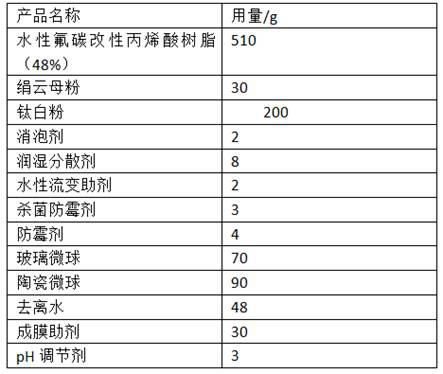

[0110] A kind of waterborne fluorocarbon modified acrylic polyurethane coating, as described in Table 1, raw material is mixed and processing steps are as follows:

[0111]

[0112] Table 1

[0113] (1) Add 48g of deionized water, 8g of wetting and dispersing agent, 2g of defoamer, and 3g of pH regulator into the dispersion tank at 300r / min, and disperse evenly for 3-5min;

[0114] (2) Preparation of white slurry: at a stirring speed of 500-800r / min, add 30g of sericite powder, 200g of titanium dioxide, and 100g of ceramic microspheres in sequence, and disperse evenly for 5-10min at a stirring speed, and then use a sand mill to Disperse to a fineness below 50 microns;

[0115] (3) Add 480g of water-based fluorocarbon modified acrylic resin to the slurry prepared in the above (2) and disperse evenly, then add 2g of water-based rheology additive and 30g of film-forming aid alcohol ester twelve at a stirring speed of 800r / min ;

[0116] (4) On the basis of (3) above, add 80...

Embodiment 3

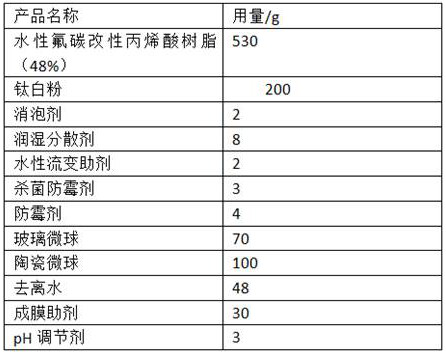

[0119] A kind of waterborne fluorocarbon modified acrylic polyurethane coating, as described in table 2, raw material is mixed and processing steps are as follows:

[0120]

[0121] Table 2

[0122] (1) Add 48g of deionized water, 8g of wetting and dispersing agent, 2g of defoamer, and 3g of pH regulator into the dispersion tank at 300r / min, and disperse evenly for 3-5min;

[0123] (2) Preparation of white slurry: at a stirring speed of 500-800r / min, add 30g of sericite powder, 200g of titanium dioxide, and 90g of ceramic microspheres in sequence, and disperse evenly for 5-10min at a stirring speed, and then use a sand mill to Disperse to a fineness below 50 microns;

[0124] (3) Add 520g of water-based fluorocarbon modified acrylic resin to the slurry prepared in the above (2) and disperse evenly, then add 2g of water-based rheology additive and 32g of film-forming aid alcohol ester twelve at a stirring speed of 800r / min ;

[0125] (4) On the basis of the above (3), add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com