Method for preparing L-glufosinate-ammonium

A technology of glufosinate-ammonium and methylphosphine dichloride, applied in the field of preparation of L-glufosinate-ammonium, can solve the problems of difficult separation, low yield, poor substrate tolerance, etc., and achieve easy-to-obtain raw materials and simple steps , cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

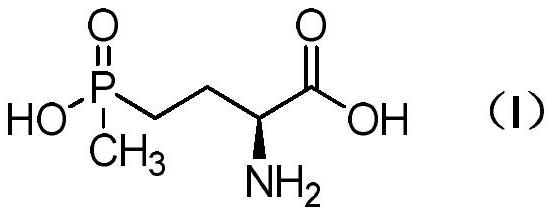

[0040] (1) Synthesis of compound 2

[0041]

[0042] In a nitrogen atmosphere, add 27.1g of compound (1) (90% ee value), 38.1g of triethylamine and 100mL of trimethylbenzene into a three-necked flask, drop down to -20°C, add 10g of methylphosphine dichloride dropwise, and keep - The reaction was stirred at 20°C, and the reaction solution was monitored by Ms. After the raw materials were completely reacted, trimethylbenzene and triethylamine were distilled off under reduced pressure to obtain 28.1 g of crude product compound (2). The molar yield based on compound (1) was 90%. The crude product compound (2) was directly used in the next step without further purification.

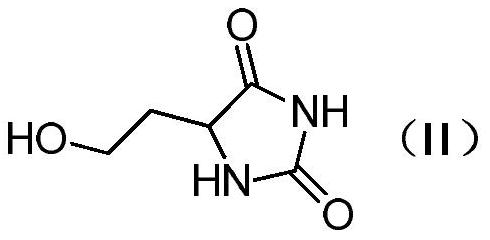

[0043] (2) Synthesis of compound 3

[0044]

[0045] Under a nitrogen atmosphere, compound (2) was dissolved in trimethylbenzene (120 mL), and 1.2 g of granular iodine was added. The temperature was raised to 150° C., and the reaction was stirred until the raw materials were completely reacted. Trimet...

Embodiment 2

[0052]According to the method of Example 1, the base type, solvent type and reaction temperature in step (1) were changed, and the results are shown in Table 1 below.

[0053] The molar yield in the table is the molar yield of compound (2) based on compound (1).

[0054] Table 1

[0055]

Embodiment 3

[0057] According to the method of Example 1, the catalyst type, solvent type and reaction temperature in step (2) were changed, and the results are shown in Table 2 below.

[0058] The molar yield in the table is the molar yield of compound (3) based on compound (2).

[0059] Table 2

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com