A titanium alloy anchor chain for ships and ocean engineering and its welding production process

A technology of marine engineering and production technology, applied in welding equipment, welding accessories, electron beam welding equipment, etc., can solve the problems of end stress concentration affecting the service life of the anchor chain, reducing the strength of the anchor chain, affecting the strength of the joint, etc. Lightweight and high-strength seawater corrosion resistance, improved connection quality, and guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1, blanking: select a high-strength titanium alloy rod with a diameter of 40mm as the raw material, the performance of the titanium alloy rod is 780MPa yield strength, 880MPa tensile strength, 12% elongation, and 35% reduction in area;

[0034] Step 2, heating: use a heating furnace to heat the titanium alloy rod coated with high-temperature anti-oxidation coating to 850°C, and keep it warm for 1 hour to ensure that the core of the titanium alloy rod is close to the surface temperature, so that the rod is completely heated;

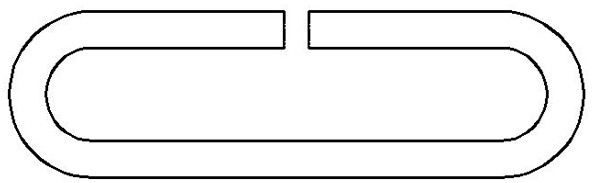

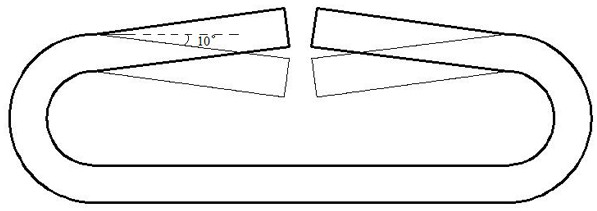

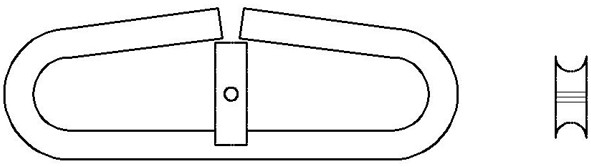

[0035] Step 3, bending ring: bend the heated titanium alloy bar on the bending ring mechanism, set the bending mandrel at the two starting positions of the titanium alloy bar to be bent, and first bend the titanium alloy bar The mandrel is bent into a U-shape with a horizontal bottom, and then the two sides of the U-shape are bent around the bending mandrel in the middle, so that the two end faces of the titanium alloy rod are close to each oth...

Embodiment 2

[0043] Step 1, blanking: select a high-strength titanium alloy rod with a diameter of 30mm as the raw material, the performance of the titanium alloy rod is 820MPa yield strength, 900MPa tensile strength, 10% elongation, and 31% reduction in area;

[0044] Step 2, heating: use an induction coil to heat the titanium alloy bar coated with high-temperature anti-oxidation coating to 940°C, and keep it warm for 30 minutes to ensure that the core of the titanium alloy bar is close to the surface temperature, so that the bar is completely heated;

[0045] Step 3, bending ring: bend the heated titanium alloy bar on the bending ring mechanism, set the bending mandrel at the two starting positions of the titanium alloy bar to be bent, and first bend the titanium alloy bar The mandrel is bent into a U-shape with a horizontal bottom, and then the two sides of the U-shape are bent around the bending mandrel in the middle, so that the two end faces of the titanium alloy rod are close to each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com