A Spray Forming Synchronous Ultrasonic Hot Finish Rolling Preparation Technology

A spray forming and hot finishing technology, applied in the field of composite materials, can solve the problems that anisotropic particles do not form a good metallurgical bond, affect the material shape, toughness and poor fatigue performance, etc., so as to eliminate blank defects and reduce process Costs, the effect of shortening the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

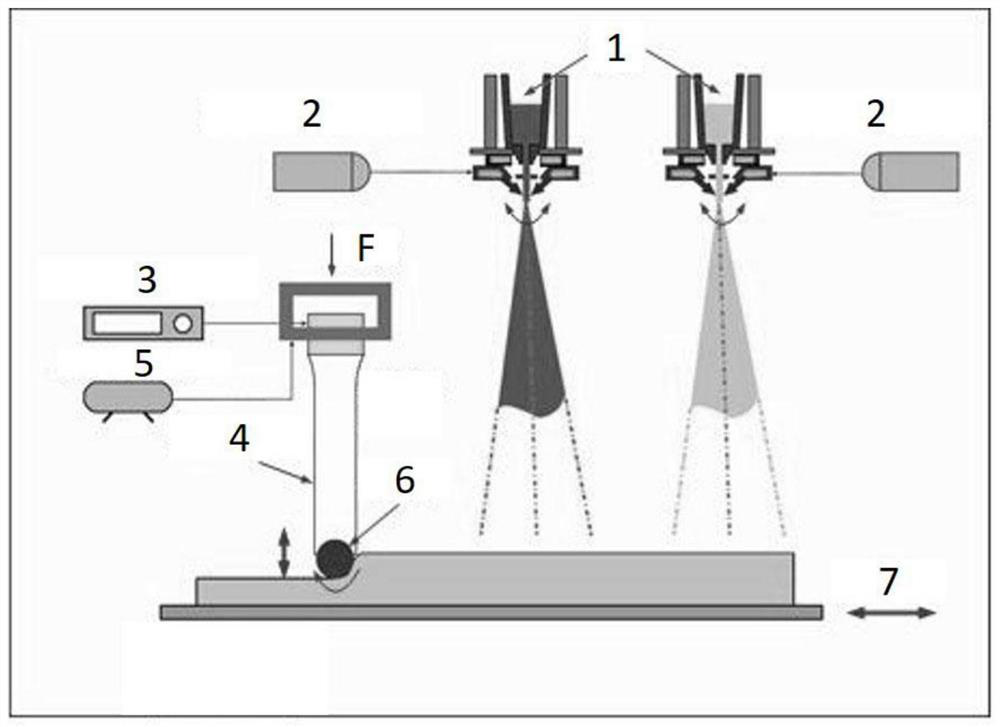

[0021] Such as figure 1 As shown, it is a schematic diagram of equipment for spray forming synchronous ultrasonic hot finish rolling of the present invention, including a spray forming device, an ultrasonic device, and a hot finish rolling device; wherein the spray forming device includes a leak bag 1, a nozzle scanning electric frequency motor 2, and a base 7; The ultrasonic device includes an ultrasonic power supply 3 and an ultrasonic working head 4; the hot finish rolling device includes a gasoline compressor 5 and an impact head 6. Its working principle can be described as: the metal melt in the leakage bag 1 flows into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com