Preparation method of nitrogen-doped graphene loaded core-shell-shaped copper-carbon composite catalyst for producing formic acid through electro-catalysis of carbon dioxide

A nitrogen-doped graphene and carbon dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as low stability and poor product selectivity , to achieve good stability, increase the adsorption capacity, and improve the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

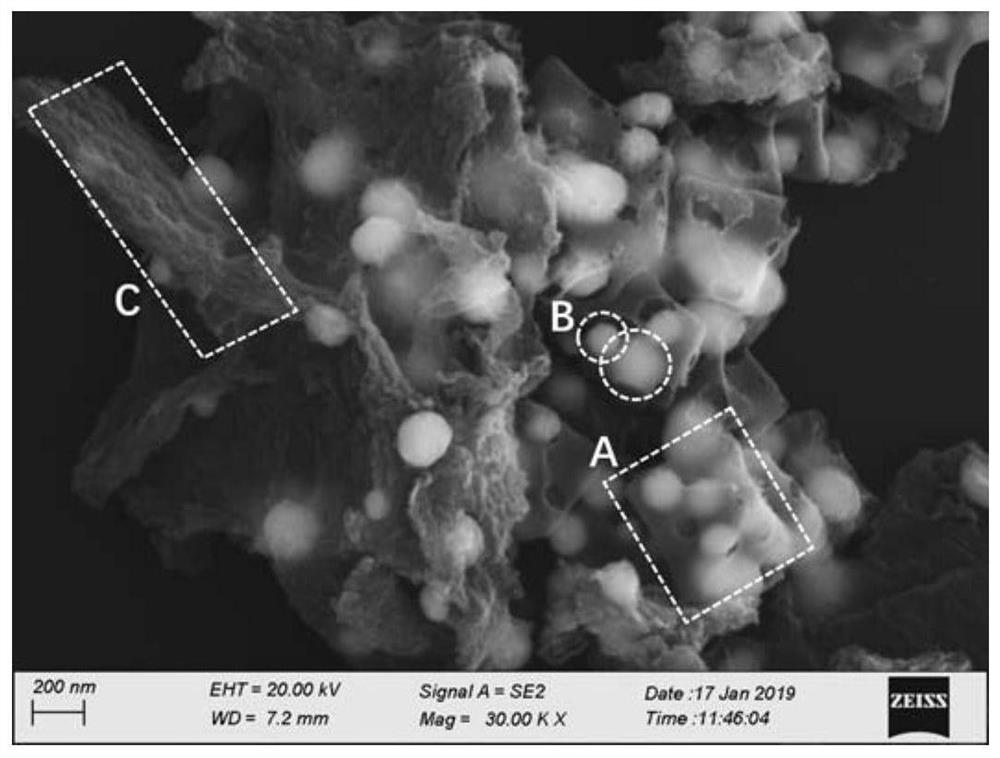

[0030] Embodiment 1: This embodiment is a method for preparing a nitrogen-doped graphene-loaded core-shell copper-carbon composite catalyst for carbon dioxide electrocatalytic production of formic acid, which is carried out according to the following steps:

[0031] 1. Configure the precursor solution:

[0032] Nitrogen-doped reduced graphene oxide was added to the mixed solution of N,N-dimethylformamide and ethanol to fully disperse, and then Cu(NO 3 ) 2 ·3H 2O continue to stir until completely dissolved to obtain a mixed solution; dissolve benzimidazole in a mixed solution of N,N-dimethylformamide and ethanol and stir until dissolved to obtain a benzimidazole solution; dissolve trimesic acid in N , Stir in the mixed solution of N-dimethylformamide and ethanol until dissolved to obtain trimesic acid solution;

[0033] Cu(NO 3 ) 2 ·3H 2 The concentration of O is 2.5mg / mL~3.0mg / mL; Cu(NO 3 ) 2 ·3H 2 The mass ratio of O to nitrogen-doped reduced graphene oxide is 1:(0.1...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the nitrogen-doped reduced graphene oxide described in step 1 is specifically prepared according to the following steps: adding graphene oxide powder into deionized water, and then Add urea and transfer to a reaction kettle, and react at a temperature of 150°C to 200°C for 3h to 8h to obtain nitrogen-doped reduced graphene oxide; the mass of the graphene oxide powder and the volume of deionized water The ratio is 1 mg:(1-5) mL; the mass ratio of the graphene oxide powder to urea is 1:(20-40). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the purity of the high-purity Ar gas described in Step 4 is 99.99%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com