Nanofiltration membrane, preparation method and application thereof

A nanofiltration membrane and microfiltration membrane technology, applied in the field of materials, can solve the problems of low filtration flux and slow diffusion, and achieve the effect of ultra-high separation water flux, high retention rate, and good mechanical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

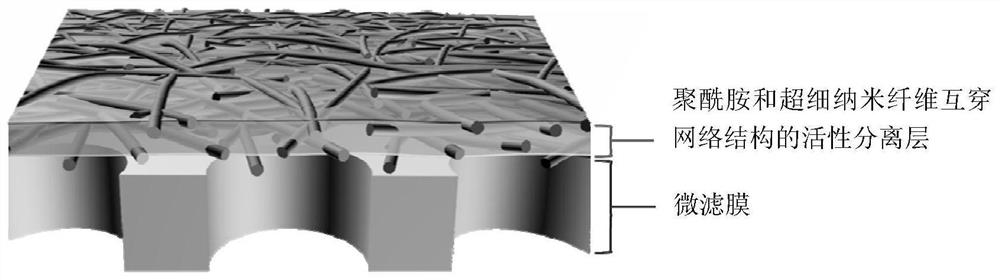

[0040] As another aspect of the technical solution of the present invention, it also relates to a preparation method of a nanofiltration membrane, which includes:

[0041] An ultrafine nanofiber layer is arranged on the microfiltration membrane to obtain an ultrafine nanofiber / microfiltration membrane composite substrate;

[0042] The polyethylenimine monomer and the acid chloride monomer are subjected to interfacial polycondensation reaction on the surface of the ultrafine nanofiber / microfiltration membrane composite substrate, followed by heat treatment to obtain the nanofiltration membrane.

[0043]The preparation principle of the nanofiltration membrane of the present invention may lie in that ultrafine nanofibers play a key role in the formation process and separation performance of the ultrathin active separation layer. First, the ultra-fine nanofibers run through the polyamide layer and play a good supporting role, making the ultra-thin polyamide layer have pressure res...

Embodiment 1

[0076] Suction filter the carbon nanotubes onto a commercial polyethersulfone microfiltration membrane with a density of 2.3 μg cm -2 . Deposit polyethyleneimine with a weight average molecular weight of 600 on the carbon nanotube substrate with a concentration of 5 mg ml -1 The solution on the surface of the membrane was soaked for 60s after soaking in aqueous solution of polyethyleneimine, and then the surface of the membrane was soaked in a concentration of 0.3mg ml -1 In the 1,3,5-trimesoyl chloride hexane solution, after reacting at 20°C for 60s, soak the membrane in hexane to wash away excess 1,3,5-trimesoyl chloride. Finally, the membrane was heated at 60 °C for 25 min and stored in deionized water.

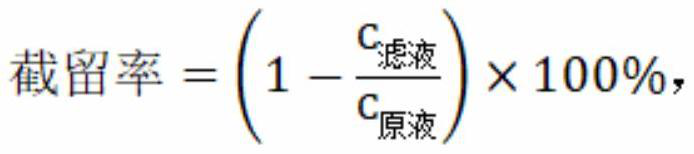

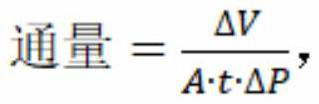

[0077] The nanofiltration membrane prepared above was used with 1000ppm MgCl 2 Aqueous solution test, the test temperature is 28°C, the operating pressure is 5bar, and the flux is 30L m -2 h -1 bar -1 , The rejection rate is 96%. The membrane is sensitive to 1000ppm...

Embodiment 2

[0079] Suction filter the carbon nanotubes onto a commercial polyethersulfone microfiltration membrane with a density of 2.3 μg cm -2 . Deposit polyethyleneimine with a weight average molecular weight of 600 on the carbon nanotube substrate with a concentration of 5 mg ml -1 The solution on the surface of the membrane was soaked in polyethyleneimine aqueous solution for 60s, and then the surface of the membrane was soaked in a concentration of 0.6mg ml -1 In the 1,3,5-trimesoyl chloride hexane solution, after reacting at 20°C for 60s, soak the membrane in hexane to wash away excess 1,3,5-trimesoyl chloride. Finally, the membrane was heated at 60 °C for 25 min and stored in deionized water.

[0080] The nanofiltration membrane prepared above was used with 1000ppm MgCl 2 Aqueous solution test, the test temperature is 28°C, the operating pressure is 5bar, and the flux is 27L m -2 h -1 bar -1 , The rejection rate is 97%. The membrane is sensitive to 1000ppm CaCl 2 The reje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com