A preparation method of a headless fiber-reinforced resin-based composite material combustion chamber shell for rockets

A fiber-reinforced resin and composite material technology, which is applied in the field of polymer-based composite material preparation, can solve the problems of poor heat insulation, low blasting strength, heavy weight, etc., and achieve the effects of increasing strength, increasing blasting pressure, and increasing shear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

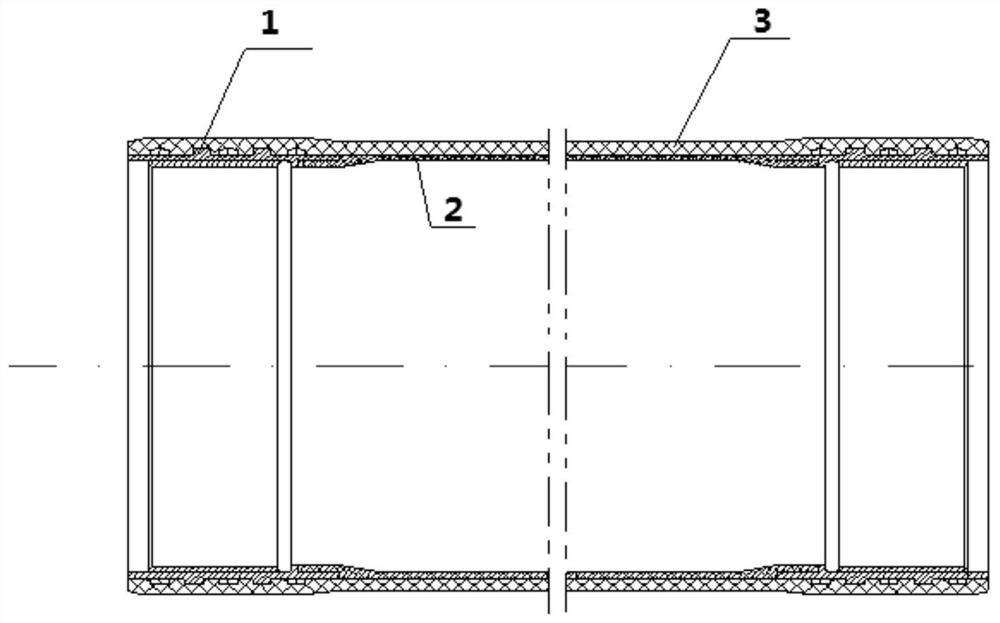

[0028] Embodiment 1: In this embodiment, a method for preparing a headless fiber-reinforced resin-based composite combustion chamber shell for rockets is specifically carried out in the following steps:

[0029] 1. Milling the surface of the outer ring of the metal ring to form a uniformly arranged wire hanging table to obtain a metal wire hanging ring;

[0030] 2. Assemble the inner lining material and the metal hanging wire ring on the mandrel to obtain the assembly parts;

[0031] 3. Put the fiber yarn into the modified epoxy resin glue for dipping, and then wrap it on the surface of the assembly obtained in step 2 to obtain the shell prefabricated part;

[0032] 4. Heat the shell preform to 90-100°C and keep it warm for 1-2 hours, then heat it to 110-120°C and keep it warm for 1-2 hours, then heat it up to 150-160°C and keep it warm for 4-6 hours, then cool and demould. The combustion chamber casing is obtained, and the preparation method of the headless fiber-reinforced ...

specific Embodiment approach 2

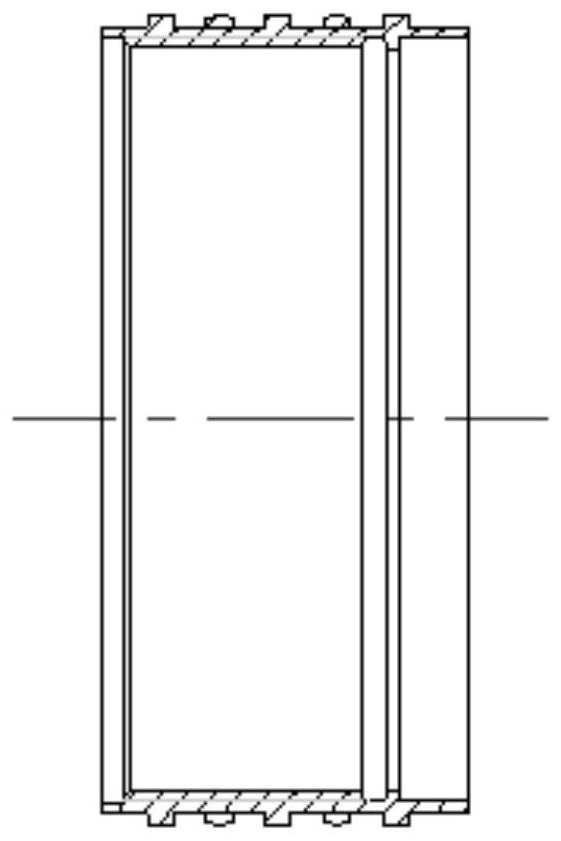

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the material of the metal ring is 30CrMnSiA or TC4; the outer diameter of the metal ring is 68-200 mm, the wall thickness is 2-5 mm, and the width is 30-80 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

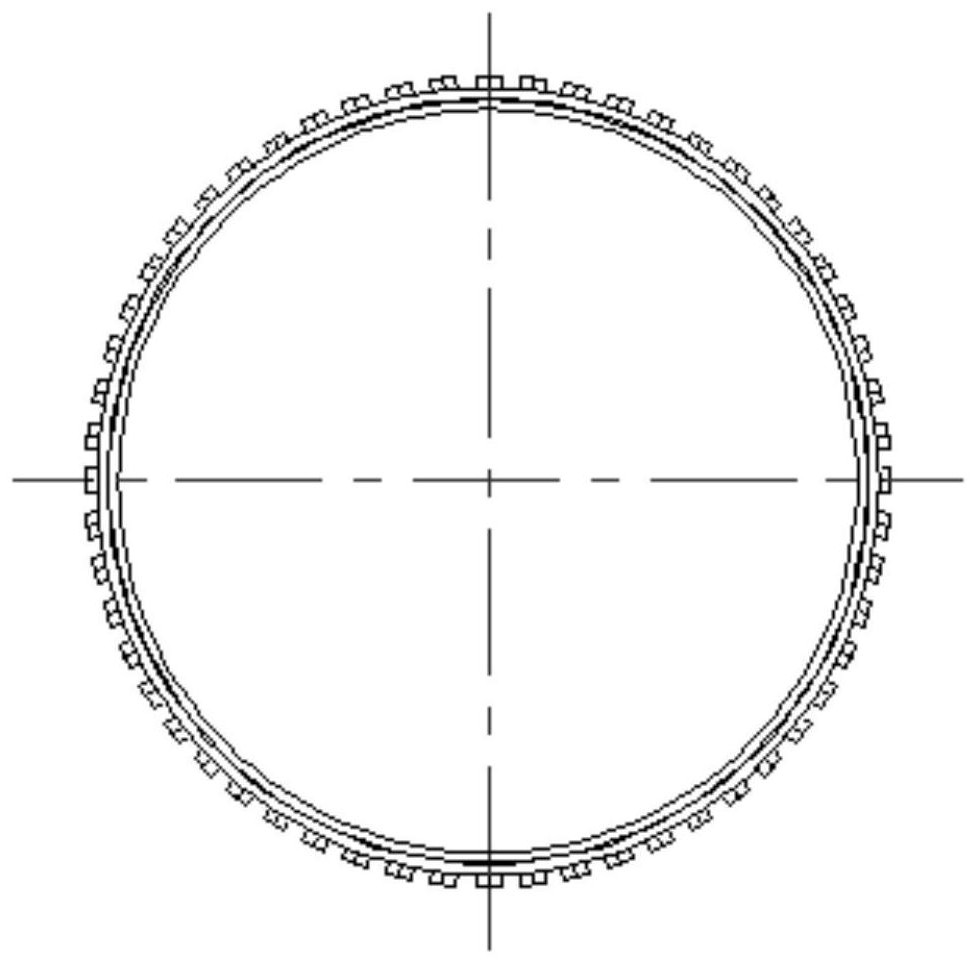

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the metal wire ring is obtained by cross milling, and the total number of wire hanging tables on the surface of the metal wire ring is 42 to 140. The number of wire hanging tables is 14 to 28, a total of 3 to 5 rings; the root of the wire hanging table is prismatic, the side length is 1 to 2 mm, the angle between adjacent sides is 45° to 90°, and the height of the wire hanging table is 0.5 ~1mm, and the upward "draft" slope is 1°~3°. Others are the same as in the first or second embodiment.

[0037] In this embodiment, the number of rings distributed on the surface of the metal wire hanging ring is 3 to 5 rings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com